200W Peliter Thermoelectric Cooling Module TEC Cooler Product Video

200W Peliter Thermoelectric Cooling Module TEC Cooler Certificate

200W Peliter Thermoelectric Cooling Module TEC Cooler Product Introduction

Thermoelectric cooling or TEC cooler is mainly made of Semiconductor refrigeration piece, Heat sink, fans, panel. TEC is small, light, easy to install, No refrigerant, no pollution to the environment, Cooling and heating functions can interchangeable, Can be connect an external emergency fan and hydrogen fan, can remote monitoring though RS485 .

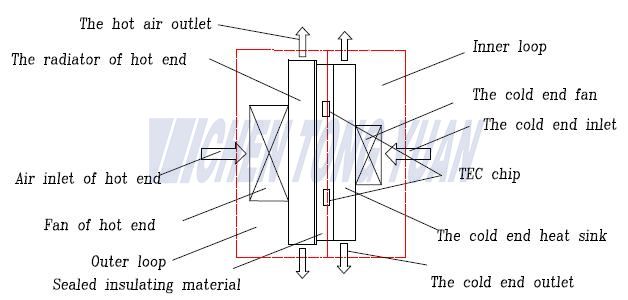

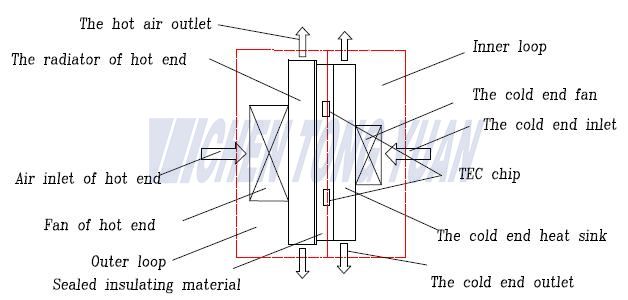

Working principle of Thermoelectric Cooling Module

When the DC flow through the circuit, which is formed by different conductor connection in nodes produces endothermic or exothermic phenomenon,this phenomenon called peltier effect .

Thermoelectric Cooling Module use in this peltier effect . When Thermoelectric cooler power on , one side cooling through the fan and the heat sink to absorb heat, contained in the other side of the heating through the fan and heat sink get heat away.

Product parameters of Thermoelectric Cooling Module

Name | TEC cooler |

Model | FF-200W-48C |

Mounting Method | Semi-embedded Mounting |

Power Supply | 48V DC |

Cooling capacity | 200W |

Power capacity | 230W |

Max Noise Level | 63dB(A) |

IP Grade | IP55 |

Net Weight | 8kg |

Dimensions | 180*400*198 (mm,W*H*D) |

More option for Thermoelectric Cooling Module

| Name | Model | Voltage | Nominal cooling capacity(W) (L35/L35) | Nominal cooling capacity(Btu/hr) (L35/L35) | Power consumption(W)(L35/L35) | IP Grade | OPERATING TEMP ℃ |

| Thermoelectric Cooling Module | A10HA1E | DC12V,DC24V,DC48V | 100 | 340 | 95 | IP55,NEMA 4, NEMA 4X | -10℃~+70℃ |

| Thermoelectric Cooling Module | A20HA1E | DC12V,DC24V,DC48V | 200 | 680 | 230 | IP55,NEMA 4, NEMA 4X | -10℃~+70℃ |

| Thermoelectric Cooling Module | A30HA1E | DC24V,DC48V | 300 | 1020 | 410 | IP55,NEMA 4, NEMA 4X | -10℃~+70℃ |

| Thermoelectric Cooling Module | A50HA1E | DC48V | 500 | 1700 | 700 | IP55,NEMA 4, NEMA 4X | -10℃~+70℃ |

| Thermoelectric Cooling Module | A70HA1E | DC48V | 700 | 2390 | 1100 | IP55,NEMA 4, NEMA 4X | -10℃~+70℃ |

Advantages of Thermoelectric Cooling Module

The thermoelectric cooling module is transforming temperature regulation with its efficiency and precision. Below are the primary benefits of using this advanced technology:

1. Energy Efficiency

The thermoelectric cooling module is incredibly energy-efficient compared to traditional cooling methods. Unlike systems that use excess power or refrigerants, thermoelectric cooling units regulate temperatures with minimal energy consumption, offering both environmental and cost benefits over time.

2. Precise Temperature Control

One of the standout features of the thermoelectric cooling module is its ability to achieve precise temperature control. Whether it's used in electronics or Semiconductor Cooling Systems, TEC modules ensure stable, accurate temperatures, critical for sensitive devices and equipment.

3. Compact and Lightweight Design

The thermoelectric cooling unit offers a compact, lightweight design, making it ideal for installations in tight spaces. Whether it's a thermoelectric panel cooler in a server rack or a cooling system for small electronic components, its space-saving nature doesn't compromise performance.

4. Fast Response Times

TEC coolers, including thermoelectric cooling modules, are known for their rapid response times. These systems can quickly adjust to temperature fluctuations, making them essential for environments where immediate cooling or heating is necessary.

5. No Refrigerants or Moving Parts

Unlike traditional cooling systems, a thermoelectric cooling module operates without refrigerants or moving parts, reducing the risk of mechanical failures. This design enhances reliability and reduces the need for maintenance, which is especially beneficial in Semiconductor Cooling Systems.

6. Silent Operation

A significant advantage of the thermoelectric cooling module is its silent operation. This makes it ideal for noise-sensitive environments such as labs, medical facilities, and office spaces. The absence of compressors and fans in thermoelectric cooling units ensures a quiet, efficient operation.

Applications of Thermoelectric Cooling Module

1. Electronics Cooling

The thermoelectric cooling module is extensively used for electronics cooling, particularly in high-performance computers and Semiconductor Cooling Systems. These modules prevent overheating, helping to extend the life of sensitive electronic components.

2. Medical Equipment

In medical devices, thermoelectric cooling modules regulate temperature-sensitive equipment like diagnostic tools, refrigerated drug storage, and laser systems. Their precise temperature control ensures the optimal functioning of critical medical equipment.

3. Aerospace Industry

The thermoelectric cooling unit is essential in aerospace applications, where it helps maintain the temperature stability of spacecraft and satellite electronics. Thermoelectric cooling modules ensure that these systems perform correctly despite the harsh temperature variations in space.

4. Vehicle Climate Control

In vehicle climate control, the thermoelectric cooling panel cooler is used to regulate interior temperatures, such as in thermoelectric cooling units for car seats. Additionally, these modules help maintain the temperature in refrigerated trucks, ensuring the safety of temperature-sensitive goods during transport.

5. Laboratory & Research Equipment

Laboratories rely on the thermoelectric cooling module to ensure the temperature stability of research equipment. Instruments like spectrophotometers, chromatographs, and DNA sequencers rely on thermoelectric cooling units for precise temperature control, ensuring accurate results.

6. Photovoltaic Solar Panels

The thermoelectric cooling module also plays a role in photovoltaic solar panels. By controlling the temperature of solar cells, thermoelectric cooling units help improve the efficiency of solar energy systems, contributing to better energy conversion.

7. Telecommunications Equipment

In telecommunications, thermoelectric cooling modules are used to cool critical network equipment like amplifiers and transceivers. This cooling ensures stable operation, preventing overheating and improving system reliability in high-demand environments.

Conclusion: The Future of Cooling Technology

The thermoelectric cooling module represents the future of temperature control, offering unmatched energy efficiency, precision, and reliability. Whether in electronics cooling, Semiconductor Cooling Systems, or medical equipment, TEC systems offer a compact, cost-effective solution. By eliminating the need for refrigerants and moving parts, thermoelectric cooling units provide an environmentally-friendly and low-maintenance alternative to traditional cooling systems.