Advantages of Thermoelectric Coolers

Energy Efficiency

Thermoelectric Cooler (TEC) technology is renowned for its exceptional energy efficiency. Unlike traditional cooling systems that rely on compressors and refrigerants, a Thermoelectric Cooler operates using the Peltier effect to transfer heat. This process significantly reduces power consumption, making Thermoelectric Cooler solutions an environmentally friendly choice. The ability of a Thermoelectric Cooler to precisely regulate temperatures without energy waste leads to lower electricity costs over time, making it a sustainable and cost-effective cooling method.

Environmentally Friendly

Thermoelectric Cooler systems eliminate the need for harmful refrigerants, thereby reducing environmental impact. Many conventional cooling technologies rely on chemicals that contribute to greenhouse gas emissions and ozone depletion. With Thermoelectric Cooler technology, there are no such harmful substances involved, making it a responsible and eco-conscious cooling solution.

Precise Temperature Control

One of the key benefits of a Thermoelectric Cooler is its precise temperature regulation. Thermoelectric Cooler units maintain consistent temperature ranges with minimal fluctuation, which is crucial for applications requiring accuracy, such as laboratory equipment, temperature-sensitive products, and delicate electronics. The Thermoelectric Cooler ensures optimal performance by preventing overheating or excessive cooling.

Adaptability Across Applications

Thermoelectric Cooler systems offer versatile applications across various industries. From medical devices to industrial machinery, a Thermoelectric Cooler adapts to specific temperature requirements. The Thermoelectric Cooler responds quickly to temperature changes, ensuring stable conditions even in environments prone to fluctuations.

Compact and Lightweight Design

A major advantage of Thermoelectric Cooler technology is its compact and lightweight design. Thermoelectric Cooler units are ideal for applications where space is limited. Unlike traditional cooling systems, a Thermoelectric Cooler does not require bulky components, making integration into small or confined spaces effortless. Additionally, the lightweight nature of a Thermoelectric Cooler enhances portability and ease of installation.

Space-Saving Integration

The compact nature of a Thermoelectric Cooler allows its integration into various applications, such as portable cooling systems, medical devices, and wearable cooling solutions. A Thermoelectric Cooler can seamlessly fit into space-constrained environments while maintaining high performance.

Fast Response Times

One of the primary advantages of a Thermoelectric Cooler is its rapid response to temperature changes. A Thermoelectric Cooler can initiate cooling or heating almost instantly, making it ideal for applications where immediate temperature adjustments are necessary. Thermoelectric Cooler technology is crucial for scenarios that demand real-time temperature control.

Instantaneous Cooling or Heating

Industries such as telecommunications, automotive applications, and food storage require precise temperature management. A Thermoelectric Cooler provides an effective and fast solution, ensuring stable conditions and enhancing operational efficiency.

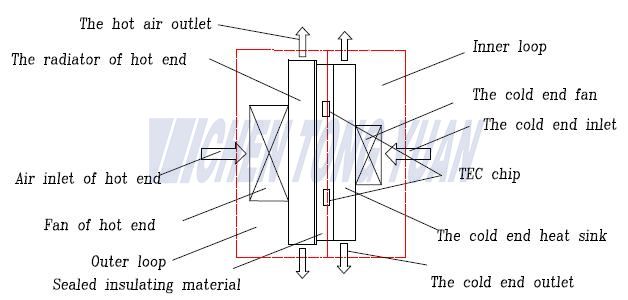

No Refrigerants or Moving Parts

Unlike traditional cooling systems that rely on compressors and refrigerants, a Thermoelectric Cooler operates with a solid-state design. This feature makes a Thermoelectric Cooler highly reliable, as there are no moving parts prone to mechanical failure. With fewer maintenance requirements, a Thermoelectric Cooler is a durable and long-lasting cooling solution.

Enhanced Durability and Reliability

The absence of moving components in a Thermoelectric Cooler minimizes wear and tear, leading to an extended operational lifespan. Additionally, without refrigerant leaks, a Thermoelectric Cooler ensures consistent efficiency and environmental safety.

Silent Operation

Thermoelectric Cooler technology is known for its silent operation. Unlike conventional cooling systems that generate significant noise due to compressors and fans, a Thermoelectric Cooler operates quietly, making it ideal for noise-sensitive environments.

Ideal for Noise-Sensitive Environments

A Thermoelectric Cooler is the preferred choice for settings such as hospitals, research labs, libraries, and residential areas where noise reduction is essential. By eliminating excessive noise, a Thermoelectric Cooler enhances comfort and maintains a peaceful environment.

Thermoelectric Cooler technology continues to revolutionize cooling solutions with its efficiency, adaptability, and environmentally friendly design. Whether for industrial, medical, or consumer applications, a Thermoelectric Cooler provides a superior alternative to traditional cooling methods.