Introduction

As the global transition to renewables accelerates, battery energy storage systems (BESS) have become indispensable for grid operators, commercial facilities, and industrial sites alike. Whether the goal is peak-shaving, backup power, or ancillary services, every successful BESS relies on a carefully orchestrated suite of hardware and software. This article examines each critical component —from the electrochemical cells to the high-level management software—and highlights international trends shaping today’s market.

1. Battery Cells & Chemistries

At the heart of any BESS are its battery modules, built from individual cells. The choice of cell chemistry profoundly affects cost, lifespan, safety, and energy density:

Lithium Iron Phosphate (LFP): Praised for inherent thermal stability and long cycle life (4,000–8,000 cycles), LFP is rapidly becoming the go-to for utility-scale and commercial installations where safety and longevity outweigh footprint constraints.

Lead-Acid & Others: While mature lead-acid technology still finds niche use in low-cost backup applications, emerging alternatives such as sodium-ion, solid-state, and high-temperature sodium-sulfur are under development to balance cost, safety, and cycle life in specialized deployments.

Today’s BESS integrators typically select LFP for high-safety grid projects and NMC/NCA for compact C&I systems, with flow batteries reserved for very long-duration needs.

2. Battery Management System (BMS)

A robust BMS ensures each cell operates safely and evenly:

Protective Actions: Automatically disconnects strings or modules if thresholds for over-voltage, over-current, or over-temperature are breached, thwarting cascade failures and thermal runaway.

Data Communication: Feeds critical status data upstream (to the PCS/EMS) and receives control commands via CAN, Modbus, or proprietary links, often in a multi-tier architecture (cell → string → system controller).

Modern BMS platforms employ predictive analytics and machine-learning models to forecast aging trends and optimize charging profiles—essential for maximizing ROI on commercial and grid-scale assets.

3. Power Conversion System (PCS) / Inverter

A Power Conversion System (PCS)—or inverter is the critical link that converts and manages bi-directional energy flow between DC battery banks and the AC grid or on-site loads. By performing high-efficiency (≥97%) AC-to-DC charging and DC-to-AC discharging, a PCS ensures seamless integration with renewable sources, maintains grid compliance (voltage, frequency, reactive power), and supports both grid-connected and islanded operation. Scalable from kilowatt to megawatt installations, modern PCS designs feature modular construction for easy maintenance, remote monitoring and control via EMS/SCADA, and robust protection against overvoltage, overcurrent, and faults. With its ability to maximize system efficiency, guarantee reliable power delivery, and enable advanced grid services such as demand response and peak shaving, a well-engineered BESS PCS inverter is essential for optimizing performance, enhancing system stability, and reducing operational costs in commercial, industrial, and utility-scale energy storage projects.

4. Energy Management System (EMS)

An Energy Management System (EMS) for Battery Energy Storage Systems (BESS) is an intelligent software platform designed to monitor, control, and optimize energy usage across storage and grid-connected systems. It enables real-time monitoring of battery performance, load balancing, and integration with renewable sources such as solar and wind. EMS optimizes charging and discharging schedules based on usage patterns, electricity pricing, and grid demand—maximizing energy efficiency, reducing costs, and extending battery life. With advanced features like remote control, data logging, predictive analytics, fault detection, and support for grid services like peak shaving and frequency regulation, EMS plays a vital role in enhancing system reliability, enabling participation in energy markets, and ensuring compliance with utility and safety standards. A well-integrated BESS EMS is essential for modern, scalable, and sustainable energy storage operations.

5. Thermal Management / HVAC

Battery Energy Storage System (BESS) thermal management and HVAC systems are critical for maintaining optimal battery performance, safety, and longevity. These systems regulate temperature (ideally between 20°C and 30°C), manage airflow, control humidity, and integrate with the Battery Management System (BMS) to prevent overheating and thermal runaway. Key components include air conditioners, heaters, fans, sensors, and heat exchangers—each supporting reliable energy storage operation in various climates. Depending on system size and environment, BESS cooling methods include air cooling, liquid cooling, or passive solutions like phase change materials (PCM). An efficient HVAC setup ensures longer battery life, improved energy efficiency, reduced maintenance costs, and compliance with safety standards such as UL 9540A. Proper BESS thermal management is essential for optimizing performance in commercial, industrial, and utility-scale energy storage applications.

6. Safety & Protection Mechanisms

Safety is multi-layered in modern BESS:

Electrical Isolation: High-voltage fuses, contactors, and breakers on both DC and AC sides instantly isolate faults, preventing sustained arcing or ground faults.

Fire Detection & Suppression: Distributed smoke, heat, and gas sensors trigger clean-agent systems (Novec 1230, FM-200) or water-mist sprinklers, quenching thermal-runaway events without damaging electronics.

Regulatory Certification: Compliance with UL 9540/9540A, NFPA 855, IEC 62619, and local codes ensures systems are tested for both electrical and fire safety, lowering permit delays and insurance premiums.

A well-engineered safety architecture not only protects lives and assets, but also underpins stakeholder confidence in large-scale energy storage deployments.

7. Enclosures & Packaging

Turnkey BESS often arrive in purpose-built shelters or ISO shipping containers:

Weatherproof & Secure: NEMA/IP-rated walls, lockable doors, and intrusion alarms protect against dust, rain, and unauthorized access.

Modular Expansion: Standardized container footprints (10 ft, 20 ft, 40 ft) allow plug-and-play capacity additions, enabling projects to scale from hundreds of kWh to hundreds of MWh with minimal engineering overhead.

Such self-contained units streamline logistics and accelerate time-to-market for both behind-the-meter and front-of-meter projects.

8. Control & Communication Infrastructure

Digital integration makes BESS a “smart” asset:

Open Protocols: CANbus/Modbus RTU for BMS links, Modbus TCP/IEC 61850/DNP3 for PCS and grid interfaces ensure interoperability with utility control centers, DERMS, and building automation systems.

This networked approach empowers asset owners to deliver grid services with millisecond responses and maintain maximum uptime.

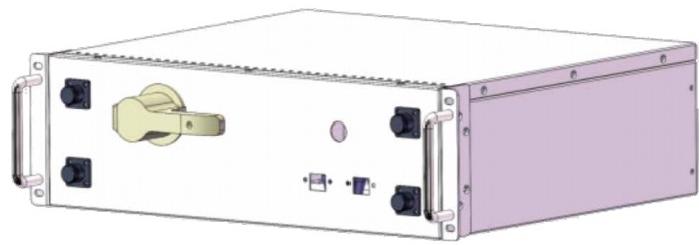

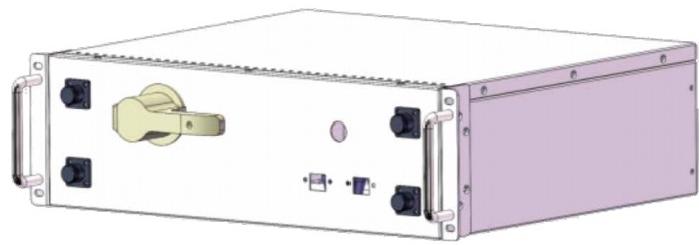

Case Spotlight: Cytech’s Industrial-Grade Control Cabinets for BESS Deployment When building a robust control and communication infrastructure for BESS, selecting field-proven industrial hardware is critical. Cytech’s NEMA 4 battery enclosure and pole-mounted control cabinets are engineered for harsh environmental conditions, making them ideal for housing critical BMS, EMS, and telemetry systems. These enclosures feature IP-rated sealing, active thermal management, SCADA-ready interfaces, and optional fiber-optic and redundant UPS configurations—ensuring continuous operation under demanding load and weather scenarios. With a modular design that allows rapid deployment and easy scalability, Cytech products have been widely adopted in solar-plus-storage and microgrid projects across North America and Southeast Asia. Their “plug-and-play” architecture helps accelerate commissioning timelines while delivering long-term reliability for commercial and industrial-scale installations.

9. Emerging Trends & Market Outlook

A few key trends are reshaping the BESS landscape:

Long-Duration Storage: Systems offering 8–12 hours of discharge (often via flow batteries or novel chemistries) are gaining traction for deep renewables integration and capacity shifting.

Second-Life Batteries: Retired EV packs repurposed for stationary storage can reduce capex by up to 30 %, though developers must account for uneven residual capacity and warranty considerations.

Hybrid Energy Hubs: Combining batteries with solar, wind, diesel/gas gensets, or hydrogen systems creates resilient microgrids and 24/7 renewable power offerings.

Virtual Power Plants (VPPs): Aggregating distributed BESS assets behind multiple meters unlocks participation in wholesale markets, enhancing revenue streams for commercial customers.

Advanced Materials: Sodium-ion, solid-state, and silicon anode technologies promise further cost reductions, safety improvements, and energy-density gains in the coming decade.

By 2030, McKinsey and BNEF forecast global BESS capacity to exceed 1 TW/4 TWh, driven by supportive policy frameworks (IRA, EU Fit for 55), EV supply chain expansion, and emerging business models like storage-as-a-service.

Conclusion

For purchasers, distributors, and system integrators in the commercial and industrial BESS arena, understanding these core components is paramount. The interplay of cell chemistry, management electronics, power conversion, thermal controls, safety systems, and digital orchestration determines not only performance and lifespan, but also project economics and regulatory compliance.

As the grid-scale energy storage market matures, the winners will be those who select the right chemistry for their application, partner with vendors offering proven BMS/PCS platforms, and implement advanced EMS and safety architectures. By staying abreast of emerging technologies—long-duration storage, second-life cells, hybrid microgrids—you can position your business to capitalize on the next wave of energy storage growth.

Invest wisely, design meticulously, and your BESS will deliver reliable, cost-effective power for years to come.