Product Video

Certificate

System Introduction

Energy storage system chiller is an integrated product developed by our company specifically for heat dissipation in the energy storage (such as battery) industry.

The applicable scenarios are as follows:

●The batteries inside the energy storage container generate a lot of heat.

●The equipment inside the energy storage container is sensitive to environmental temperature.

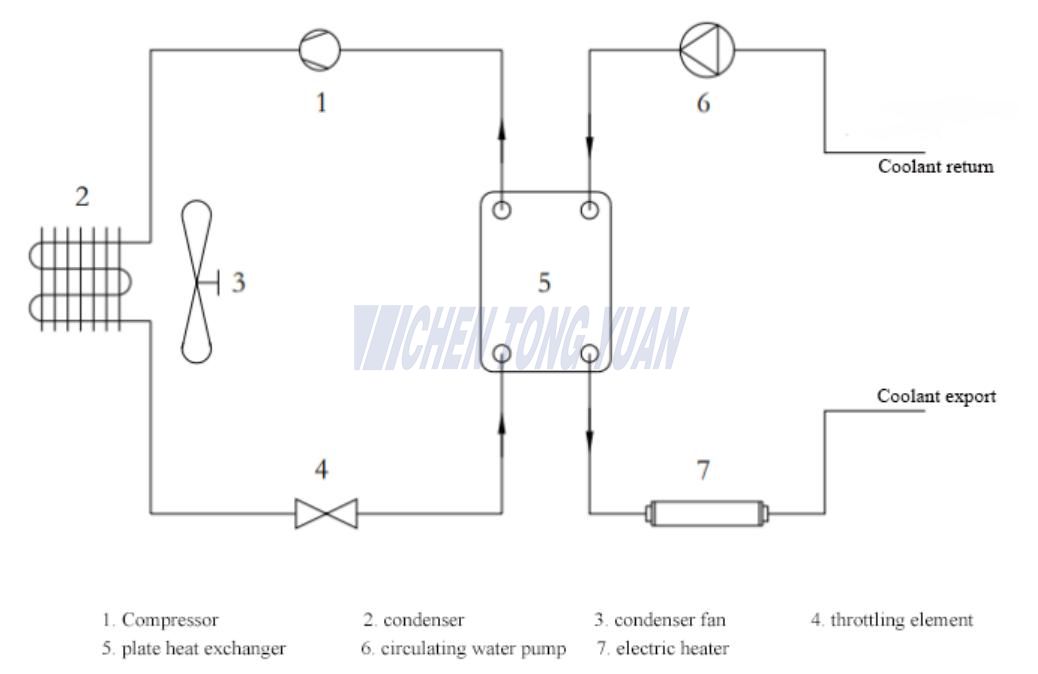

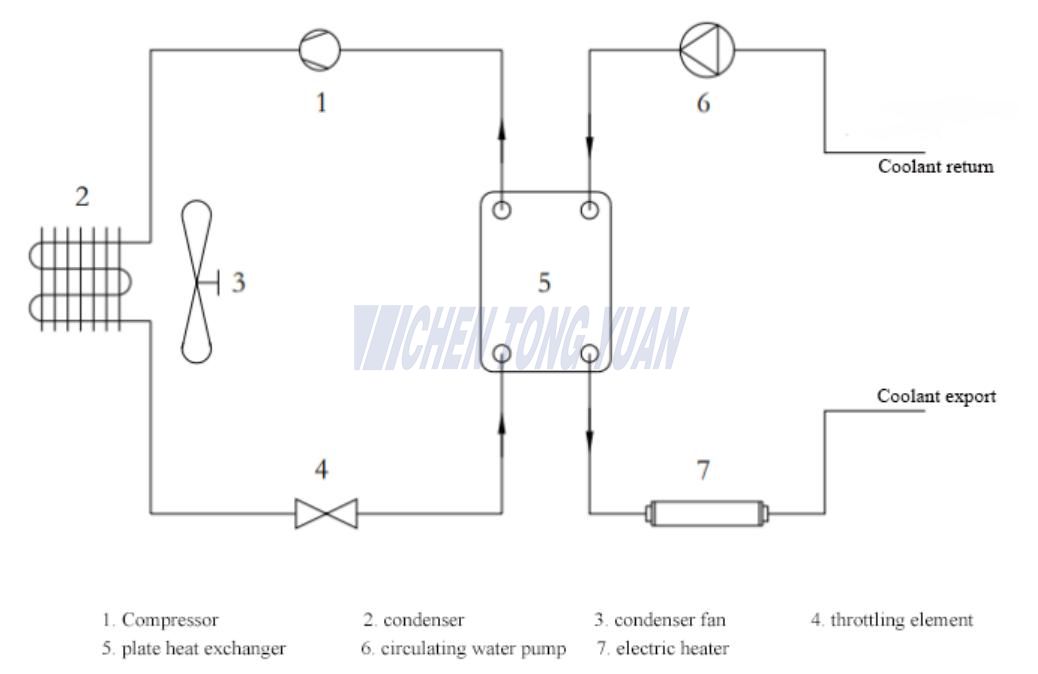

System principle

Energy storage system air-cooled chiller consists of a refrigeration system and a coolant circulation system, and the system principle is shown in the figure:

The Energy Storage System chiller is currently a popular direction for power battery thermal management. It utilizes the performance of coolant with large heat capacity and the ability to remove excess heat from the battery system through circulation to achieve suitable working temperature conditions for battery packs. The basic components of the liquid cooling system include: liquid cooling plate, liquid cooling unit (heater optional), liquid cooling pipeline (including temperature sensor, valve), high and low voltage wiring harness; cooling liquid (ethylene glycol aqueous solution), etc.

● Compressor: responsible for compressing the refrigerant and providing power for the refrigerant system.

● Condenser: Designed with a parallel flow microchannel heat exchanger, it has high heat transfer efficiency, and the refrigerant condenses and releases heat in the condenser.

● Condenser fan: centrifugal fan is used to provide high static pressure and large air volume, which is responsible for discharging the heat released by the refrigerant in the condenser to the outside.

● Throttling element: Electronic expansion valve is used to control the refrigerant flow rate through adjustment.

● Plate heat exchanger: The plate heat exchanger is the intersection of the refrigeration cycle system and the coolant cycle system, responsible for the heat exchange between the refrigerant and the coolant.

● Circulating water pump: responsible for conveying coolant and providing power for the coolant circulation system.

● Electric heating: responsible for heating the coolant.

Parameters of Energy storage system chillers

Model | CY-ESSC40 |

Rated Voltage(V) | 380AC±15﹪ |

Rated frequency(Hz) | 50±2﹪ |

Cooling capacity(KW) | 45.6 |

Heating load(KW) | 6.5 |

Rated power(KW) W15/L35 | 20.5 |

Rated current(A)W15/L35 | 24.5 |

Refrigerant | R407C/8.0kg |

Circulating water volume | 500L/min |

Coolant | 50% ethylene glycol aqueous solution |

Working Ambient Temperature | -30℃~+55℃ |

Water inlet and outlet method | Top inlet and outlet water |

IP grade | IP20 |

Weight | 540Kg |

Overall dimensions(W*D*H) |

995mm*995mm*2200mm |

Function of Water Chillers in Energy Storage Systems

Temperature Regulation in Energy Storage Systems

Water chillers play a crucial role in maintaining the desired temperature within an energy storage system. Temperature regulation is essential for the efficient functioning of energy storage systems, ensuring optimal performance and enhancing their longevity. By controlling the thermal environment, chillers help manage the heat generated during energy storage and retrieval processes.

Improving System Efficiency with Energy Storage Cooling System

The efficiency of an energy storage system directly depends on maintaining an optimal temperature range. By effectively managing heat, energy storage cooling systems ensure that the system operates at peak efficiency. This helps minimize energy losses and allows for faster charging and discharging cycles. A well-regulated temperature environment contributes to higher efficiency in both storing and releasing energy.

Preventing Thermal Degradation in Energy Storage Systems

Thermal degradation can significantly impact the performance and lifespan of an energy storage system. Chillers are vital in preventing this issue by maintaining the storage medium within the prescribed temperature limits. This is especially important in thermal energy storage systems where a precise temperature range is necessary to prevent damage to the storage material, ensuring the system’s long-term effectiveness.

In summary, energy storage cooling systems, particularly water chillers, are integral to optimizing the performance, efficiency, and longevity of energy storage systems. Their role in temperature regulation, system efficiency, and preventing thermal degradation is essential to the success of modern energy storage solutions.

Advantages of Energy Storage Cooling System

Optimal Temperature Control with Industrial Precision Backpack Type Air Conditioning (AC) Units

Energy storage systems rely heavily on maintaining a stable thermal environment to ensure their efficient operation. Industrial precision backpack type air conditioning (AC) units provide the precise temperature regulation needed for these systems. These AC units are specifically designed to manage the varying thermal loads within energy storage facilities, ensuring that both the storage medium and the entire system function optimally. By maintaining a consistent temperature range, industrial precision AC units prevent overheating and improve the overall lifespan of the energy storage system.

Efficiency and Reliability in Server Room Air Conditioners

The use of server room air conditioners within energy storage systems brings an added layer of efficiency and reliability. These specialized units are designed to cool high-density areas, ensuring that the components of the energy storage system, such as servers or storage devices, stay within the ideal temperature limits. This not only maximizes performance but also reduces the risk of thermal damage, which could lead to costly downtime or system failure. Server room air conditioners, when integrated with an energy storage cooling system, significantly enhance the overall operational reliability.

Sustained Performance of Energy Storage Cooling System

An energy storage cooling system plays a pivotal role in the continuous performance of energy storage solutions. By using advanced cooling techniques like industrial precision backpack type air conditioning (AC) units and server room air conditioners, energy storage systems can operate efficiently, even under demanding conditions. These cooling systems help preserve the integrity of the stored energy and minimize energy losses. Additionally, by regulating temperature consistently, they prevent thermal degradation, which can otherwise diminish storage capacity and affect the system’s longevity.

In conclusion, the advantages of an Energy Storage Cooling System are clear: they ensure optimal temperature control, enhance system efficiency, and prevent potential thermal damage. The integration of industrial precision backpack type air conditioning (AC) units and server room air conditioners is key to maximizing the performance and reliability of energy storage systems.