Outline

1. Introduction

Importance of Cooling Electrical Panels

Overview of Cost-Effective Solutions

2. Understanding Electrical Panel Overheating

Causes of Overheating

Consequences of Overheating

3. The Basics of Electrical Panel Cooling

What is Electrical Panel Cooling?

Benefits of Proper Cooling

4. Passive Cooling Solutions

Natural Ventilation

Heat Sinks

5. Active Cooling Solutions

Fans and Blowers

Air Conditioning Units

6. Hybrid Cooling Solutions

Combining Passive and Active Cooling

Examples of Hybrid Solutions

7. Innovative Cooling Technologies

Liquid Cooling

Thermoelectric Cooling

8. Energy-Efficient Cooling Practices

Optimizing Cooling System Settings

Regular Maintenance and Inspections

9. Cost Analysis of Cooling Solutions

Initial Costs vs. Long-Term Savings

Return on Investment (ROI)

10. Case Studies

Successful Implementation in Various Industries

Lessons Learned from Failures

11. Choosing the Right Cooling Solution

Assessing Your Specific Needs

Factors to Consider

12. Installation and Maintenance Tips

Best Practices for Installation

Routine Maintenance Guidelines

13. Common Mistakes to Avoid

Overlooking Proper Ventilation

Ignoring Regular Maintenance

14. Future Trends in Electrical Panel Cooling

Emerging Technologies

Predictions for the Next Decade

15. Conclusion

Recap of Key Points

Final Thoughts

16. FAQs

What are the signs that my electrical panel is overheating?

How often should I inspect my cooling systems?

Can I install cooling solutions myself, or do I need a professional?

What is the most cost-effective cooling solution for small businesses?

Are there any eco-friendly cooling options available?

Introduction

Keeping electrical panels cool is crucial for maintaining the efficiency and longevity of electrical systems. Overheating can lead to equipment failure, costly repairs, and even dangerous fire hazards. In this guide, we'll explore a variety of cost-effective cooling solutions for electrical panels, ensuring your systems run smoothly without breaking the bank.

Understanding Electrical Panel Overheating

Causes of Overheating

Electrical panels can overheat due to several factors, including inadequate ventilation, high ambient temperatures, and excessive electrical load. Poorly maintained equipment and clogged filters can also contribute to rising temperatures within the panel.

Consequences of Overheating

When an electrical panel overheats, it can cause damage to the internal components, leading to malfunctions and potential safety risks. In extreme cases, overheating can result in fires, posing significant danger to personnel and property.

The Basics of Electrical Panel Cooling

What is Electrical Panel Cooling?

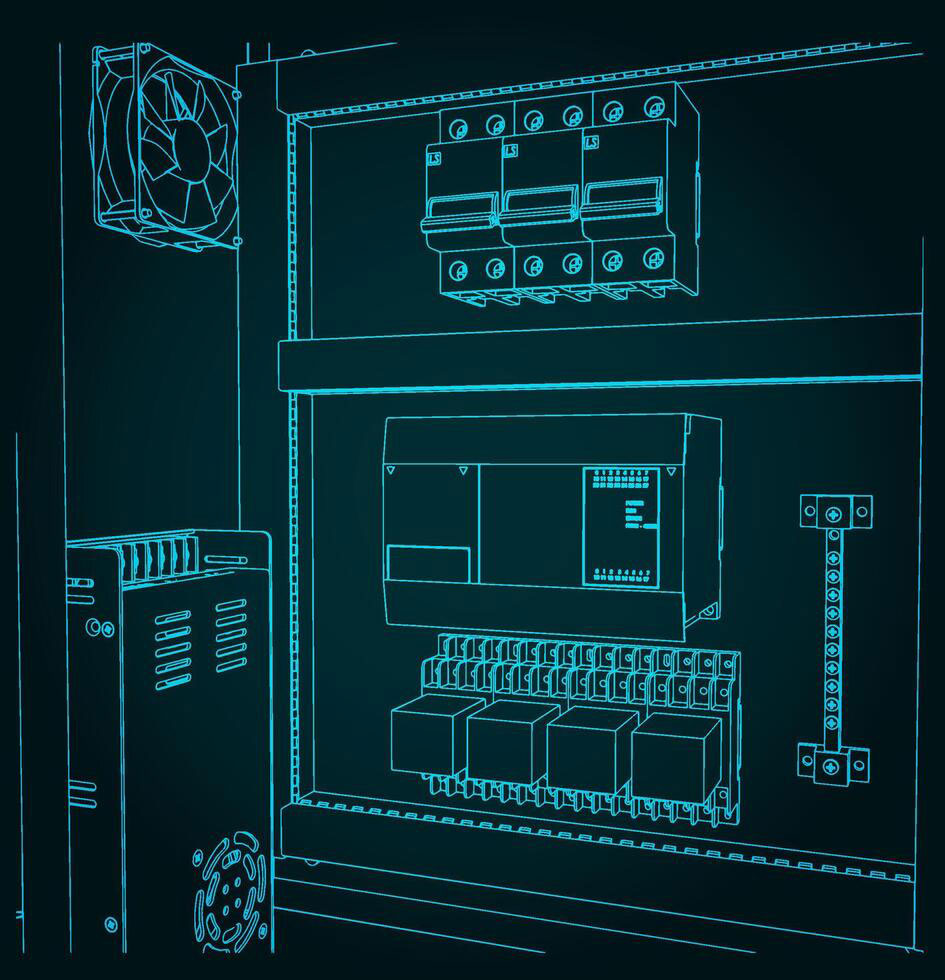

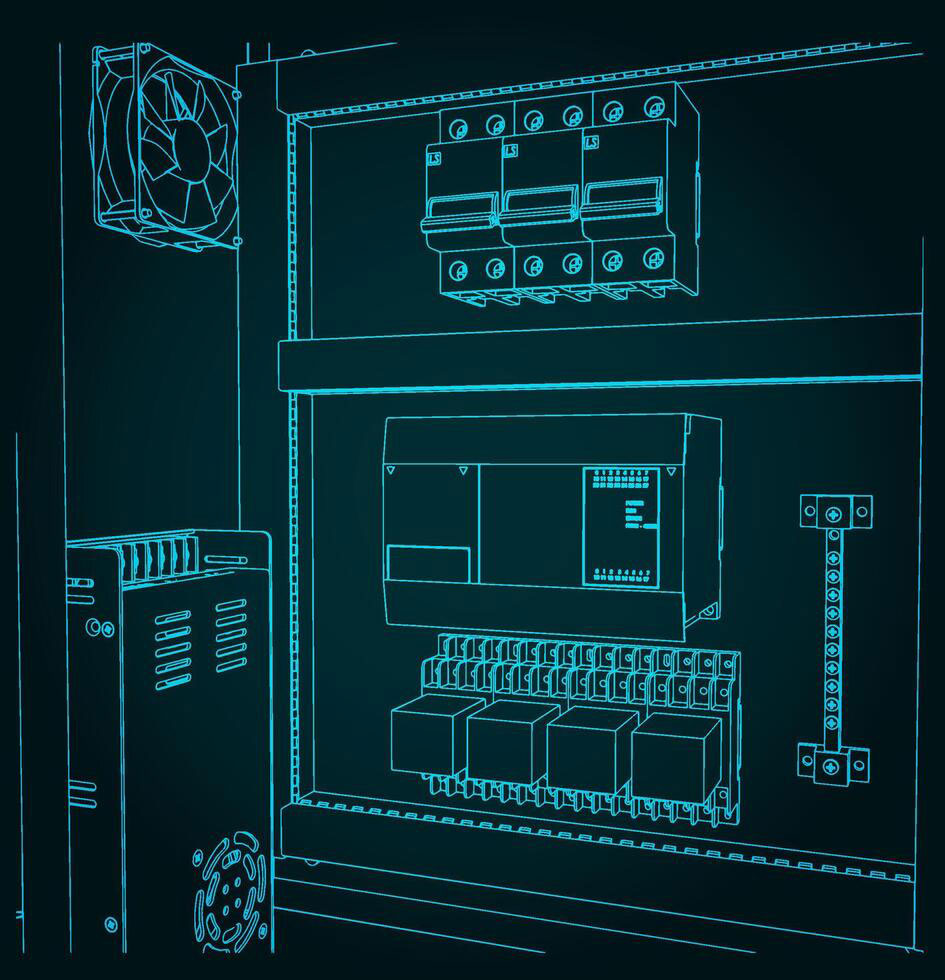

Electrical panel cooling (electrical panel cooling ac) refers to the various techniques and devices designed to manage and regulate the temperature within electrical panels, ensuring that electrical components operate within their optimal temperature range. This cooling process is vital for maintaining the efficiency, longevity, and reliability of electrical systems. Cooling methods can vary from basic passive techniques like ventilation to more advanced solutions such as active cooling systems, including air conditioners and heat exchangers.

The primary goal of electrical panel cooling is to dissipate the heat generated by the electrical components, such as circuit breakers, switches, and transformers, which can accumulate due to electrical resistance, high loads, or external environmental factors. Effective cooling prevents overheating, which can lead to component failure, reduced operational lifespan, or even fire hazards in extreme cases.

Benefits of Proper Cooling

Extended Lifespan of Electrical Components

Prolonged exposure to high temperatures can degrade electrical components, causing them to fail prematurely. Proper cooling reduces the risk of thermal stress, preserving the integrity and operational life of critical components like circuit breakers, transformers, and relays.

Improved Performance

Electrical components operate most efficiently within a specific temperature range. By maintaining an optimal temperature through effective cooling, the performance of the system remains consistent, and energy efficiency is maximized. Heat buildup can cause components to work harder, leading to inefficiencies and higher energy consumption.

Reduced Risk of Failures and Downtime

Overheating is a leading cause of electrical failures, which can result in costly downtime. By implementing an effective cooling system, the likelihood of overheating is significantly reduced, improving system reliability and reducing maintenance costs.

Enhanced Safety

Overheating of electrical panels can pose serious safety risks, including the potential for fires or electrical accidents. Effective cooling methods mitigate these risks by maintaining safe operational temperatures and reducing the chance of overheating-related accidents.

Compliance with Industry Standards

Many industries, such as manufacturing, utilities, and telecommunications, have strict guidelines regarding temperature control within electrical systems. Proper cooling ensures compliance with these regulations, preventing fines and legal complications.

Conclusion

Electrical panel cooling is an essential aspect of maintaining the integrity and functionality of electrical systems, especially in demanding environments where heat generation is inevitable. Whether through passive ventilation or more advanced electrical panel cooling methods such as air conditioning or liquid cooling, selecting the right cooling solution can significantly extend the life of electrical components, improve system performance, and ensure safety. By understanding and implementing the appropriate cooling techniques, businesses can optimize their electrical systems for maximum efficiency and reliability.

Passive Cooling Solutions

Natural Ventilation

One of the simplest and most cost-effective cooling solutions is natural ventilation. By allowing air to flow freely through the panel, heat can escape naturally, reducing the overall temperature.

Heat Sinks

Heat sinks are devices that absorb and dissipate heat from electrical components. They are easy to install and require no power, making them an efficient passive cooling option.

Active Cooling Solutions

Fans and Blowers

Installing fans and blowers inside the electrical panel can help circulate air and cool down the components. These devices are relatively inexpensive and can be highly effective when properly maintained.

Air Conditioning Units

For environments with higher cooling demands, electrical panel air conditioning units can be used to regulate the temperature within electrical panels. Although more costly upfront, they provide reliable cooling for critical systems.

Hybrid Cooling Solutions

Combining Passive and Active Cooling

Hybrid cooling solutions leverage the strengths of both passive and active methods. For instance, combining natural ventilation with strategically placed fans can enhance cooling efficiency without significantly increasing costs.

Examples of Hybrid Solutions

A common hybrid solution is using heat sinks alongside fans to maximize heat dissipation. Another example is integrating air conditioning with natural ventilation for large, high-heat-generating panels.

Innovative Cooling Technologies

Liquid Cooling

Liquid cooling involves circulating a coolant through the panel to absorb and remove heat. This method is highly effective but can be more expensive and complex to implement.

Thermoelectric Cooling

Thermoelectric cooling air conditioner (thermo tec air conditioner) uses semiconductor materials to create a temperature difference and transfer heat away from the panel. This technology is energy-efficient and can be used in compact spaces.

Energy-Efficient Cooling Practices

Optimizing Cooling System Settings

Adjusting the settings of your cooling systems to match the specific needs of your electrical panel can save energy and reduce costs. Avoid overcooling, which can be as wasteful as overheating.

Regular Maintenance and Inspections

Routine maintenance and inspections are crucial for ensuring your cooling systems operate efficiently. Clean filters, check for blockages, and ensure all components are functioning properly.

Cost Analysis of Cooling Solutions

Initial Costs vs. Long-Term Savings

While some cooling solutions may have higher initial costs, they often result in long-term savings through reduced energy consumption and prolonged equipment life.

Return on Investment (ROI)

Calculating the ROI of different cooling solutions can help you determine the most cost-effective option for your needs. Consider both direct savings and indirect benefits such as reduced downtime and maintenance costs.

Case Studies

Successful Implementation in Various Industries

Examining case studies of successful cooling solution implementations can provide valuable insights. Industries like manufacturing, data centers, and telecommunications often share their best practices.

Lessons Learned from Failures

Learning from failures is equally important. Understanding common pitfalls and how to avoid them can help you make better decisions when selecting and implementing cooling solutions.

Choosing the Right Cooling Solution

Assessing Your Specific Needs

Evaluate your specific cooling requirements based on factors like the size of the electrical panel, heat generation, and environmental conditions. This assessment will guide you in selecting the most appropriate solution.

Factors to Consider

Consider factors such as cost, energy efficiency, ease of installation, and maintenance requirements when choosing a cooling solution. Balancing these factors will help you achieve optimal performance and cost savings.

Installation and Maintenance Tips

Best Practices for Installation

Proper installation is key to the effectiveness of your cooling solution. Follow manufacturer guidelines, ensure proper placement of cooling devices, and double-check all connections.

Routine Maintenance Guidelines

Regular maintenance is essential for the longevity and efficiency of your cooling systems. Schedule periodic inspections, clean components, and replace any faulty parts promptly.

Common Mistakes to Avoid

Overlooking Proper Ventilation

Neglecting ventilation can lead to overheating, even with cooling systems in place. Ensure that there is adequate airflow within and around the electrical panel.

Ignoring Regular Maintenance

Failing to perform regular maintenance can result in reduced efficiency and increased costs. Establish a maintenance schedule and stick to it to keep your cooling systems in top shape.

Future Trends in Electrical Panel Cooling

The field of electrical panel cooling is evolving rapidly, driven by the increasing need for efficiency, reliability, and sustainability in electrical systems. As electrical panels are becoming more complex and energy-dense, the demand for advanced cooling solutions, such as electrical panel coolers, is growing. Future trends are expected to focus on innovative technologies and methods that offer better performance, energy efficiency, and environmental sustainability.

Emerging Technologies

Advanced Materials for Heat Dissipation

One of the major areas of innovation is the development of advanced materials that offer better thermal conductivity and heat dissipation capabilities. Materials like graphene, advanced ceramics, and carbon nanotubes are being explored for their potential to improve the cooling performance of electrical panel coolers. These materials can increase the efficiency of heat transfer, allowing for more compact and effective cooling solutions.

Smart Cooling Systems

The integration of smart technology into electrical panel cooling is a key trend. Smart cooling systems can monitor the temperature of the electrical panel in real time and adjust the cooling methods accordingly. For instance, sensors and IoT (Internet of Things) devices can detect heat buildup and trigger the activation of cooling mechanisms such as fans, air conditioners, or liquid cooling systems when necessary. These systems can also send alerts for preventive maintenance, ensuring continuous operation and reducing downtime.

Thermal Energy Storage

Another emerging technology is the use of thermal energy storage systems in electrical panel cooling. These systems store excess heat generated during peak periods and release it later when cooling demand is lower. This can improve overall energy efficiency and reduce the burden on electrical panel coolers during high-demand periods, thus optimizing the cooling process.

Predictions for the Next Decade

Eco-Friendly Cooling Solutions

As sustainability becomes more critical, there will be a shift towards environmentally friendly cooling methods. Traditional air conditioning systems, which rely on refrigerants, may give way to electrical panel coolers that use natural cooling fluids or even evaporative cooling methods that consume less energy and produce fewer greenhouse gases. Companies are increasingly looking to minimize their carbon footprint, and the adoption of eco-friendly cooling technologies will align with these goals.

Integration with Renewable Energy Sources

The integration of renewable energy sources like solar or wind power into the cooling systems of electrical panels is another trend to watch. By harnessing renewable energy to power cooling systems, companies can achieve significant reductions in energy consumption and costs. This approach can be especially beneficial in remote locations where access to traditional energy grids may be limited.

More Efficient and Compact Cooling Solutions

As electrical panels become smaller and more energy-dense, cooling systems will need to become more compact without compromising performance. Innovations such as micro-cooling technologies and miniature heat exchangers will allow electrical panel coolers to fit into tighter spaces while still effectively dissipating heat. These systems will provide high performance in a smaller footprint, which is essential for modern electrical systems in confined environments.

Integration of AI and Machine Learning

The future of electrical panel cooling may also involve the use of artificial intelligence (AI) and machine learning algorithms to predict and adjust cooling needs dynamically. By analyzing historical temperature data and predicting load fluctuations, AI-powered systems can optimize the operation of electrical panel coolers, reducing energy usage while maintaining optimal cooling levels. These intelligent systems can also predict potential failures, enabling preemptive maintenance actions before an issue arises.

Wireless and Remote Monitoring

Wireless monitoring systems will become more prevalent in the coming years. These systems will allow operators to remotely monitor and control the temperature and cooling status of electrical panels, making it easier to manage multiple systems and reduce the need for on-site intervention. Integration with mobile apps or cloud-based platforms will enable users to access real-time data, receive notifications, and adjust cooling settings from anywhere.

Conclusion

In conclusion, cooling electrical panels effectively is crucial for maintaining system performance and safety. By understanding the various cost-effective cooling solutions available, you can make informed decisions that balance efficiency and budget. Regular maintenance and staying updated on emerging technologies will ensure your cooling systems remain effective for years to come.

FAQs

1. What are the signs that my electrical panel is overheating?

Signs of overheating include unusual noises, burning smells, discoloration, and frequent tripping of circuit breakers.

2. How often should I inspect my cooling systems?

Cooling systems should be inspected at least once every six months, but more frequent checks may be necessary in high-demand environments.

3. Can I install cooling solutions myself, or do I need a professional?

While some cooling solutions can be installed by individuals with basic technical knowledge, more complex systems should be installed by professionals to ensure proper functioning.

4. What is the most cost-effective cooling solution for small businesses?

For small businesses, passive cooling solutions like natural ventilation and heat sinks are often the most cost-effective and easy to implement.

5. Are there any eco-friendly cooling options available?

Yes, eco-friendly options include energy-efficient fans, thermoelectric cooling, and advanced materials designed for better heat dissipation with minimal environmental impact.