Outline

1. Introduction

2. Understanding Thermoelectricity

3. The Seebeck Effect

4. The Peltier Effect

5. The Thomson Effect

6. How Thermoelectric Coolers Work

7. Materials Used in Thermoelectric Coolers

8. Design and Construction

9. Advantages of Thermoelectric Coolers

10. Limitations and Challenges

11. Applications of Thermoelectric Coolers

12. Recent Advances and Innovations

13. Future Prospects

14. Environmental Impact

15. Conclusion

16. FAQs

Introduction

Imagine a cooler that doesn't use any refrigerants, has no moving parts, and can fit in the palm of your hand. This is not science fiction but the reality of thermoelectric coolers. These innovative devices have revolutionized how we think about cooling by leveraging the science of thermoelectricity. In this article, we’ll dive deep into the fascinating world of thermoelectric coolers, exploring how they work, their benefits, and their various applications.

What Are Thermoelectric Coolers?

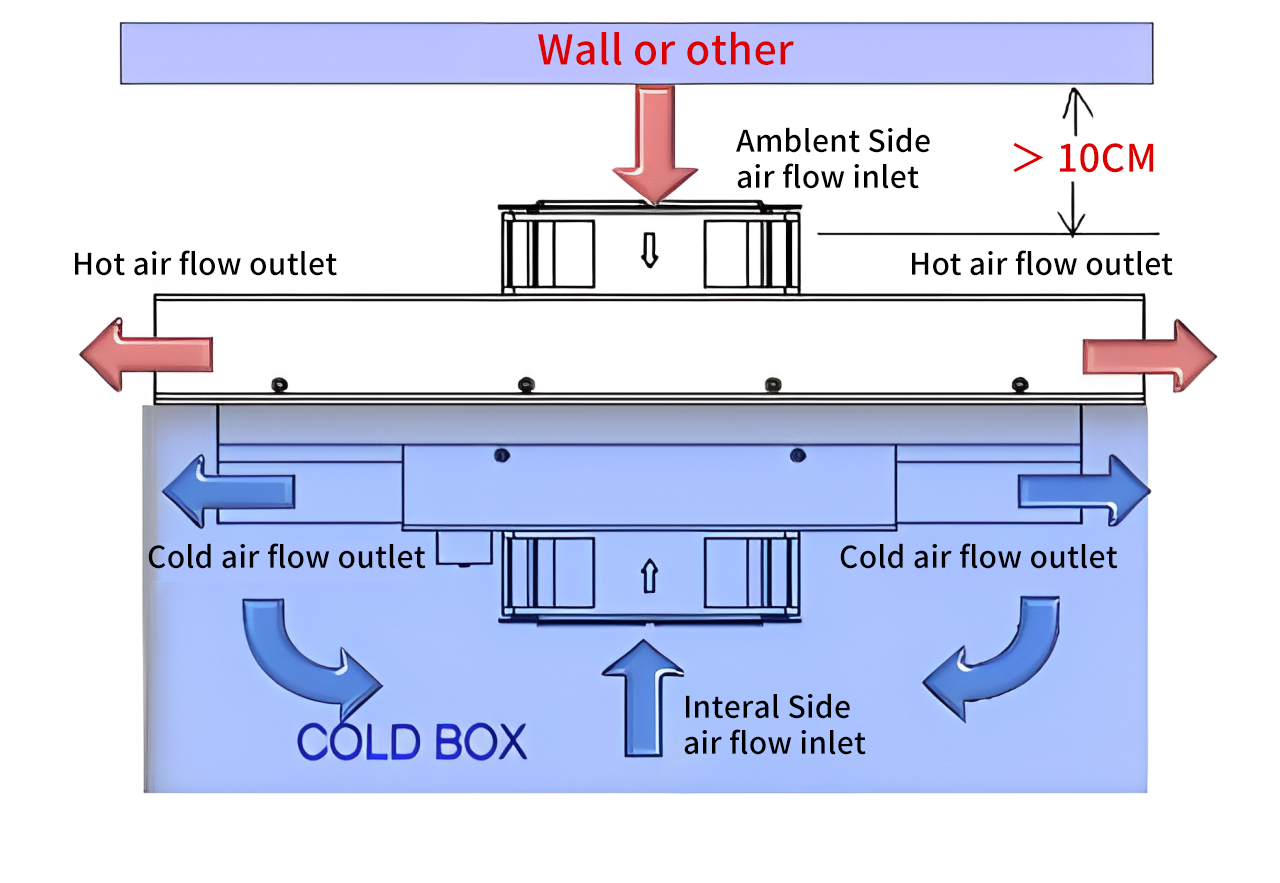

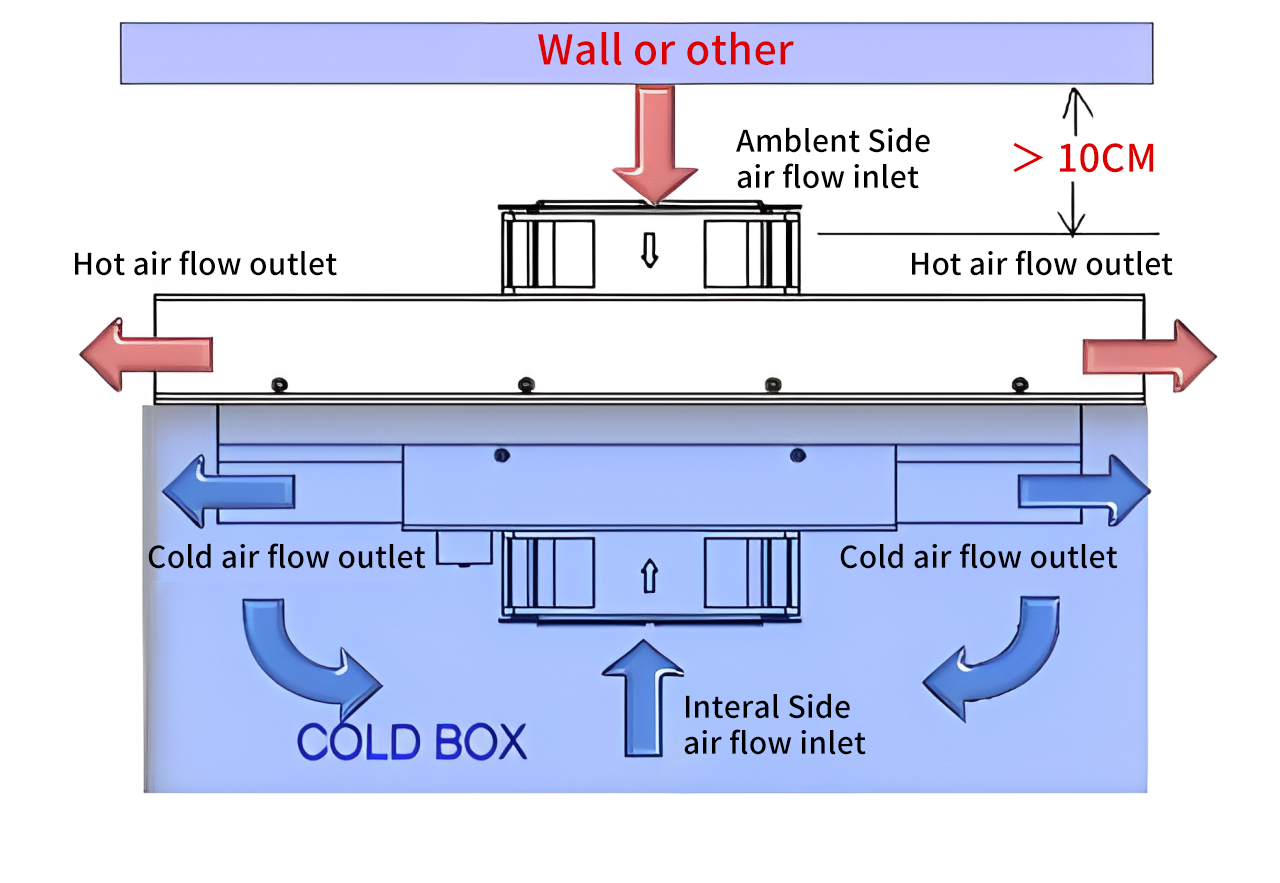

Thermoelectric coolers (TECs) are solid state thermoelectric air conditioner devices that use electrical energy to create a temperature difference. They consist of semiconductor materials sandwiched between two ceramic plates. When an electric current passes through these materials, it causes heat to move from one side to the other, effectively cooling one side while heating the other.

700W Thermoelectric Peltier Air Conditioner

Importance and Applications

Thermoelectric coolers (thermoelectric ac units) are crucial in various fields due to their ability to provide precise temperature control without moving parts. Their applications range from cooling electronic components and medical devices to providing refrigeration in portable coolers.

Understanding Thermoelectricity

Basic Concept of Thermoelectricity

Thermoelectricity involves the direct conversion of temperature differences to electric voltage and vice versa. This phenomenon is a result of thermoelectric effects, primarily the Seebeck effect, the Peltier effect, and the Thomson effect.

Historical Background

The discovery of thermoelectric effects dates back to the early 19th century, with scientists like Thomas Johann Seebeck and Jean Charles Athanase Peltier laying the foundation for modern thermoelectric technology.

The Seebeck Effect

Discovery and Explanation

The Seebeck effect, discovered by Thomas Johann Seebeck in 1821, occurs when a temperature difference between two dissimilar electrical conductors or semiconductors produces a voltage difference. This effect is the basis for thermocouples used in temperature measurement.

Practical Applications

The Seebeck effect is widely used in power generation, where thermoelectric generators convert heat into electrical energy, providing power in remote or off-grid applications.

The Peltier Effect

Discovery and Explanation

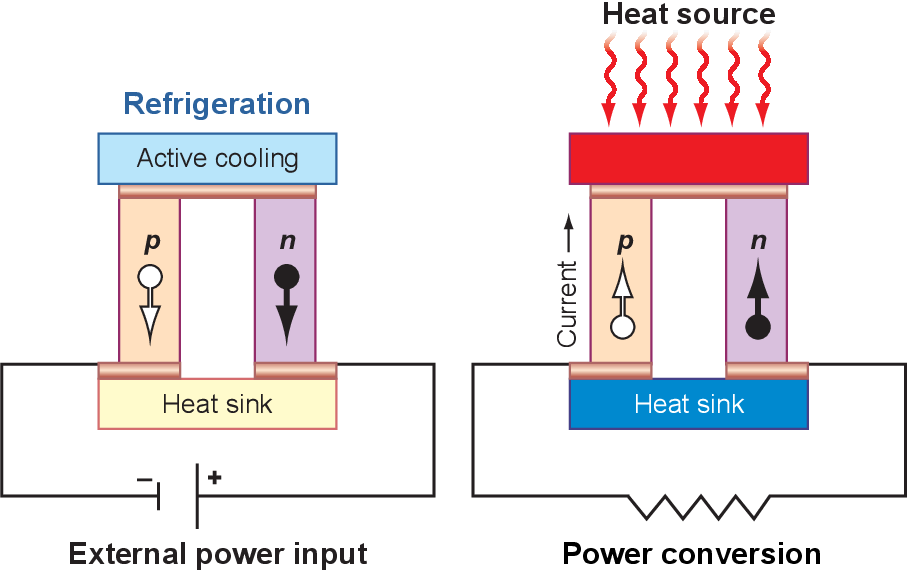

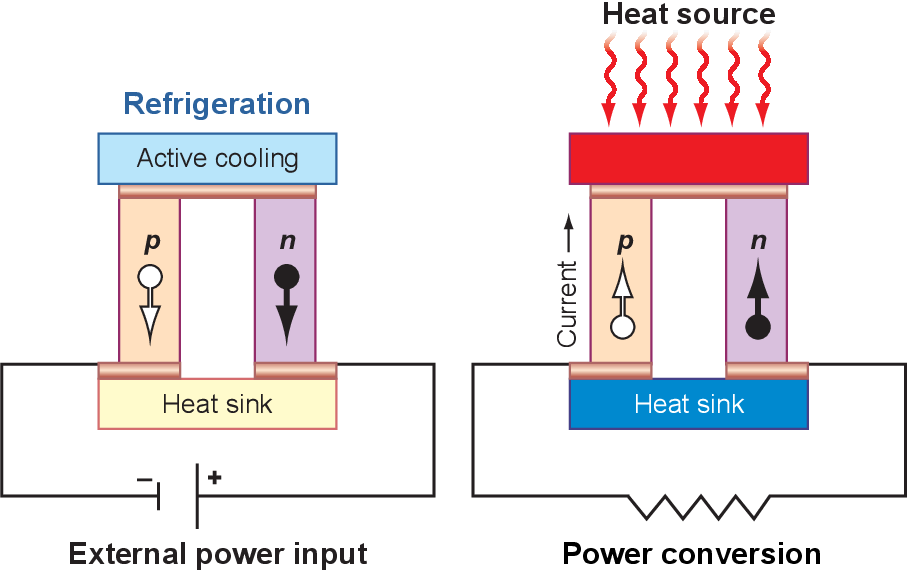

The Peltier effect, discovered by Jean Charles Athanase Peltier in 1834, describes the heating or cooling at the junction of two different conductors when an electric current flows through them. This effect is the fundamental principle behind thermoelectric coolers.

How It Relates to Thermoelectric Coolers

In a thermoelectric cooler (thermoelectric ac) , the Peltier effect is used to transfer heat from one side of the device to the other, effectively cooling one side while heating the other. This process is reversible, allowing for precise temperature control.

The Thomson Effect

Explanation and Relevance

The Thomson effect, discovered by William Thomson (Lord Kelvin) in 1851, describes the heating or cooling of a conductor with a temperature gradient along its length when an electric current passes through it. This effect is less pronounced than the Seebeck and Peltier effects but still plays a role in thermoelectric devices.

Impact on Thermoelectric Devices

The Thomson effect can influence the performance of thermoelectric coolers, particularly in terms of efficiency and temperature control. Understanding this effect helps in optimizing the design of thermoelectric systems.

How Thermoelectric Coolers Work

Basic Mechanism

At the heart of a TEC are thermoelectric modules made of n-type and p-type semiconductor materials. When a direct current (DC) passes through these modules, electrons move from the p-type to the n-type material, carrying heat with them. This movement causes one side of the module to cool down (cold side) and the other side to heat up (hot side). The heat from the hot side is typically dissipated using a heat sink, enhancing the cooling effect.

Components of a Thermoelectric Cooler

To function effectively, a TEC system comprises several key components:

Thermoelectric Modules

These are the core units where the thermoelectric effect takes place. They are composed of multiple pairs of n-type and p-type semiconductors.

Heat Sinks

Heat sinks are attached to the hot side of the module to dissipate the absorbed heat into the environment, maintaining the temperature difference.

Power Supply

A DC power supply provides the necessary electrical current to drive the thermoelectric modules.

Materials Used in Thermoelectric Coolers

Common Materials

Thermoelectric coolers typically use materials such as bismuth telluride (Bi2Te3), lead telluride (PbTe), and silicon-germanium (SiGe) alloys. These materials are chosen for their high thermoelectric efficiency and stability.

Advances in Materials Science

Recent advancements in materials science have led to the development of new thermoelectric materials with improved efficiency and performance. Nanostructured materials and complex alloys are being explored to enhance thermoelectric properties.

Design and Construction

Typical Structure

A typical thermoelectric cooler consists of multiple thermoelectric modules sandwiched between two ceramic plates. The modules are connected electrically in series and thermally in parallel to maximize the temperature difference and heat transfer.

Importance of Design in Efficiency

The design of thermoelectric coolers is crucial for their efficiency. Factors such as the arrangement of thermoelectric elements, the choice of materials, and the integration of heat sinks play a significant role in determining the performance of the device.

Advantages of Thermoelectric Coolers

TECs offer several benefits over traditional cooling systems:

Environmental Benefits

Unlike conventional refrigeration systems, TECs do not use refrigerants, which can be harmful to the environment. They are also quieter since they lack moving parts.

Efficiency and Control

TECs provide precise temperature control and can be easily adjusted by varying the input current. This makes them highly efficient for specific applications.

Reliability and Durability

With no moving parts, TECs are highly reliable and have a long lifespan, requiring minimal maintenance.

Limitations and Challenges

Efficiency Issues

Despite their advantages, thermoelectric coolers face challenges in terms of efficiency. They are generally less efficient than traditional cooling methods like vapor-compression refrigeration, which limits their widespread adoption.

Cost Considerations

The cost of thermoelectric materials and the complexity of manufacturing thermoelectric devices can be higher than conventional cooling systems, posing a barrier to their broader use.

Applications of Thermoelectric Coolers

Consumer Electronics

Thermoelectric coolers are commonly used in consumer electronics to manage heat in devices such as CPUs, GPUs, and portable refrigerators. They provide efficient cooling in compact and portable designs.

Industrial Uses

In industrial applications, thermoelectric coolers are used for precise temperature control in processes such as laser cooling, telecommunications, and instrumentation.

Medical Devices

Thermoelectric coolers are also employed in medical devices to maintain the temperature of sensitive biological samples, medical lasers, and portable diagnostic equipment.

Recent Advances and Innovations

Nanotechnology

Nanotechnology is playing a significant role in advancing thermoelectric coolers. Nanostructured materials have shown promise in improving thermoelectric efficiency by reducing thermal conductivity and enhancing electrical conductivity.

Hybrid Systems

Hybrid systems that combine thermoelectric cooling with other cooling methods, such as vapor-compression or liquid cooling, are being explored to overcome efficiency limitations and provide more effective cooling solutions.

Future Prospects

Potential Developments

The future of thermoelectric coolers looks promising, with ongoing research focused on discovering new materials, improving device efficiency, and reducing costs. These developments could lead to more widespread use of thermoelectric cooling technology.

Integration with Renewable Energy Sources

Thermoelectric coolers have the potential to be integrated with renewable energy sources, such as solar and waste heat recovery systems, to provide sustainable and eco-friendly cooling solutions.

Environmental Impact

Eco-friendliness

Thermoelectric coolers are environmentally friendly because they do not use harmful refrigerants, which are common in traditional cooling systems. This makes them an attractive option for reducing greenhouse gas emissions.

Comparison with Traditional Cooling Methods

Compared to traditional cooling methods, thermoelectric coolers offer benefits in terms of reduced environmental impact, lower maintenance requirements, and the potential for integration with renewable energy sources.

Conclusion

Thermoelectric coolers represent a fascinating intersection of physics and engineering, leveraging thermoelectric effects to provide reliable and precise cooling solutions. While they face challenges in terms of efficiency and cost, ongoing research and advancements in materials science hold the promise of overcoming these hurdles. The future of thermoelectric coolers looks bright, with potential developments in hybrid systems and integration with renewable energy sources paving the way for more sustainable and efficient cooling technologies.

FAQs

What is the primary principle behind thermoelectric coolers?

The primary principle behind thermoelectric coolers is the Peltier effect, which involves the transfer of heat from one side of a device to the other when an electric current passes through it.

How efficient are thermoelectric coolers compared to traditional coolers?

Thermoelectric coolers are generally less efficient than traditional cooling methods like vapor-compression refrigeration, but they offer advantages such as no moving parts, reliability, and eco-friendliness.

Can thermoelectric coolers be used for heating?

Yes, thermoelectric coolers can be used for heating as well. By reversing the direction of the current, the device can switch from cooling to heating.

What are some common applications of thermoelectric coolers?

Common applications of thermoelectric coolers include cooling electronic components, portable refrigerators, medical devices, laser cooling, and telecommunications.

What advancements are being made in the field of thermoelectric cooling (thermoelectric peltier cooler air conditioner)?

Advancements in the field of thermoelectric cooling include the development of nanostructured materials, hybrid cooling systems, and integration with renewable energy sources to improve efficiency and sustainability.