System Installation

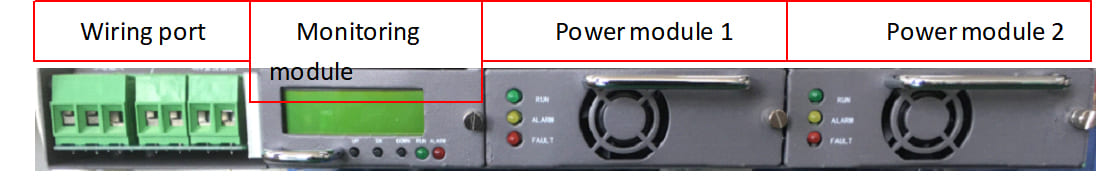

When the E4860 system is packaged and transported, the monitoring module and all rectifier modules have been installed on the system mainframe, as shown in the figure (the system configuration capacity is 60A, that is, it consists of two 4830 rectifier modules and one monitoring module).

E4860 Main Chassis (Front View)

E4860 Main Chassis (Rear View)

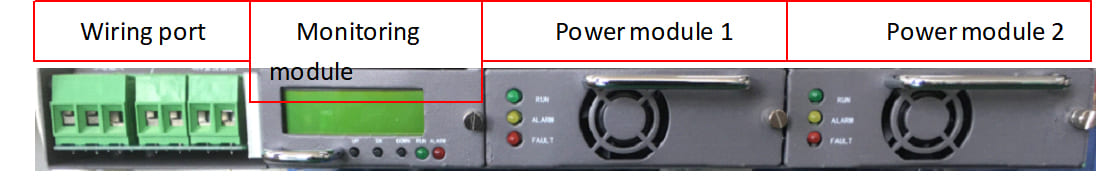

Electrical connection between the main cabinet and the outside

Electrical connection between the main cabinet and the outside

Description of electrical connection

The main cabinet make its electrical connection with the outside through its system interface board. Interface position of the system interface board is shown in the figure.

System interface board interface position diagram of E4860 power supply

Description of wiring terminals connection:

AC input interface: L (Line), N (Neutral), PE (ground);

From left to right: output cathode, output anode, battery anode, battery cathode,

Electrical connection process

The electrical connection between the main cabinet and the external equipment includes: connection of AC input, connection of DC output and storage battery, connection of communication wire, and connection of grounding wire. As will be described in detail below, the key point of electrical connection is safety and reliability.

(1) System AC lead-in connection

The AC lead-in of E4860 system is terminal block, which is located on the front panel of the system; The AC connecting wire can be connected directly.

Notice

1. The AC lead-in wire is a high-voltage working wire. During operation, it is necessary to ensure that the AC input is powered off. During operation, temporary prohibition signs shall be added to the switches that are not allowed to be used.

2. AC wire terminal contacts and other unnecessary exposed places shall be fully insulated.

3. Must be grounded before power on.

(2) System DC working wire connection

Load wire connection

The load terminals of the E4860 system are the "LOAD + and LOAD-" terminals, which are located on the front panel of the system and can be wired directly.

A. The selection and routing of the load wire shall be based on the engineering design requirements, and the appropriate cable shall be selected.

B. Connect one end of the positive connecting wire to the "LOAD +" terminal on the front panel of the system;

C. Connect one end of the negative connecting wire to the "LOAD-" end on the front panel of the system;

Battery cable connection

The wiring between the system and the battery is terminal block, marked with "BAT +" and "BAT-", which is used to connect the battery. The connecting wire can be directly connected to the terminal block. The following is a detailed description of the battery connection process.

A. Prepare the positive and negative connecting wires (including connecting the terminal and positive or negative identification).

B. Tie up the battery cable.

C. Connect one end of the positive connecting wire to the BAT + terminal on the rear panel of the system;

D. Connect one end of the negative connecting wire to the BAT- terminal on the rear panel of the system;

(3) Ground wire installation

Protective grounding connection: connect the chassis grounding point of the system main chassis to the external grounding busbar with a wire of more than 6mm2.

(4) Installation of communication wire

The communication wire interface RS485 of the E4860 system is located on the rear panel of the system. RS485 is a communication port for communication with the position machine.

RS485 communication mode:

A. Connect one end of the communication wire to RS485 on the rear panel of E4860.

B, connecting the other end of the communication wire to RS485 of the position machine, wherein the positive terminal and the negative terminal of RS485 respectively correspond to the positive terminal and the negative terminal of RS485.

Installation inspection

(1) Contents: check the installation stability of the frame body and each assembly units.

(2) AC lead-in and power distribution inspection: whether the AC wire chromatogram is standardized, whether the original wiring of the rack is loose, and whether the safety signs of the AC power distribution part are complete. Check the AC wiring and the use of wires according to the design data.

(3) Check the DC output and battery connection area, number and wire sequence polarity, check the stability of cable connection area, check the correctness and reliability of busbar connection, and re-check the battery connection polarity and sequence.

(4) Set all switches at the off position.

Installation instructions of monitoring module and rectifier module

The installation position of the monitoring module and the rectifier module on the E4860 system main chassis is shown in the figure.

Schematic Diagram of Installation Position of Components on E4860 Main Chassis

1. Two 4830 rectifier module slots.

2. One monitoring module interface slot.

The panels of the monitoring module and the rectifier module are provided with handles. When inserting into the main chassis, hold the handle with one hand and hold up the component with the other hand, and slowly push it into the corresponding slot until the connecting terminal of the rear panel of the component is inserted into the corresponding socket of the motherboard of the main chassis system. Finally, tighten the fixing screw on the upper side of the panel on the main chassis, and the installation is completed. When each component exits the main chassis, loosen the fixing screws on the upper side of the panel, hold the handle tightly, and slowly withdraw the component from the corresponding slot.

Notice

The 4830 module has the function of plug and play, but the indicator lights on the module panel must all be off before the module is inserted.

Electrical connection between the main cabinet and the outside

Electrical connection between the main cabinet and the outside