Introduction

When it comes to staying cool, especially in confined or specific areas, panel air conditioners (panel ACs) offer a versatile and efficient solution. Unlike traditional air conditioning systems, panel air conditioners are designed to meet the unique demands of industrial, commercial, and even residential spaces. This article will provide an in-depth look at these innovative cooling systems, exploring their features, benefits, and potential drawbacks. Whether you're searching for a panel AC manufacturer or just curious about how these units work, we’ve got you covered.

What Are Panel Air Conditioners (Panel ACs)?

Panel air conditioners, often referred to as enclosure air conditioners or cabinet air conditioners, are specialized cooling units designed to regulate the temperature within electrical and electronic enclosures. Unlike traditional air conditioning units, which are meant to cool living spaces, panel air conditioners focus on maintaining an optimal environment for sensitive equipment. This ensures they operate within safe temperature ranges. This makes them essential in industrial and commercial settings where equipment reliability is crucial. Panel AC manufacturers provide these systems, offering a range of solutions to meet diverse needs across sectors.

Working Principle of Panel Air Conditioners (Panel ACs)

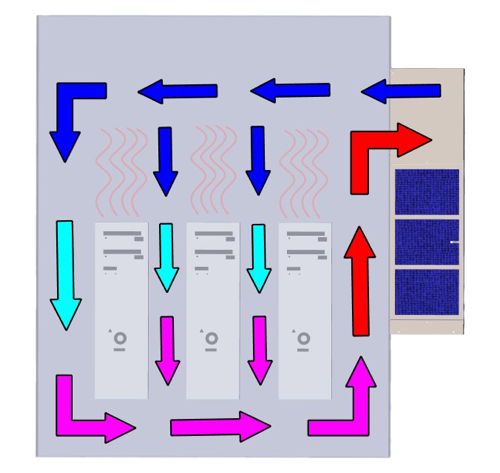

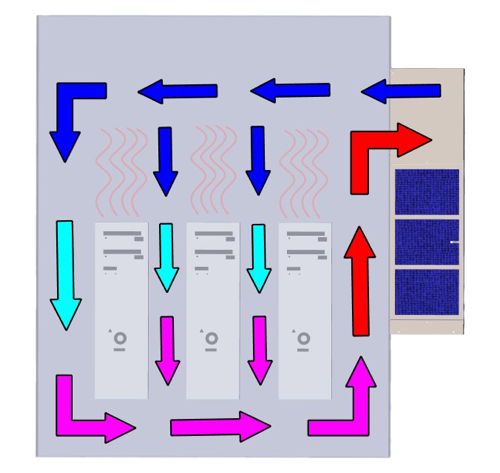

Panel air conditioners (panel ac) work on the same basic principle as traditional air conditioning units, involving the refrigeration cycle. The process begins with the evaporator coil, where the refrigerant absorbs heat from the enclosure, converting from a liquid to a gas. The compressor then pressurizes this gas, increasing its temperature. The heat is expelled outside the enclosure through the condenser coil, where the refrigerant returns to a liquid state, ready to start the cycle again. This continuous process ensures that the temperature inside the enclosure remains within the desired range.

Key components of a panel air conditioner include the evaporator, condenser, compressor, fans, and thermostat. These units are specifically designed to handle the heat loads generated by electrical components, which can be much higher than that of an average living space.

Types of Panel Air Conditioners (Panel ACs)

Panel air conditioners are available in various types, tailored to different applications:

1. Thermoelectric Panel Air Conditioners (Panel ACs)

Thermoelectric air conditioners (peltier thermoelectric air conditioner) use the Peltier effect to create a temperature difference across a semiconductor, allowing for heat transfer without the need for refrigerants. These units are compact, making them ideal for small enclosures or areas with space constraints. They are also reliable and maintenance-free, as they have no moving parts.

Key Features:

Solid-state cooling technology

No refrigerants or compressors

Silent operation

Suitable for small-scale applications

2. Vapor-Compression Panel Air Conditioners (Panel ACs)

Vapor-compression air conditioners are the most common type of panel air conditioners. They work by compressing refrigerant gas, which is then condensed and evaporated to cool the air within the enclosure. These units are effective for larger enclosures and can handle higher heat loads.

Key Features:

High cooling capacity

Suitable for larger enclosures

Efficient heat dissipation

Requires refrigerants and compressors

3. Passive Heat Exchangers

Passive heat exchangers don’t use active cooling methods like compressors or fans. Instead, they rely on the natural convection of air to transfer heat from the interior of the enclosure to the outside environment. These units are energy-efficient but may not be suitable for high heat load applications.

Key Features:

Energy-efficient with no power consumption

No moving parts, low maintenance

Ideal for moderate cooling needs

Limited to low to moderate heat loads

4. Closed-Loop Air Conditioners

Closed-loop air conditioners are designed to keep the internal environment of an enclosure isolated from the external atmosphere. This prevents contaminants such as dust, dirt, and moisture from entering the enclosure, making them ideal for harsh industrial environments.

Key Features:

Protects against environmental contaminants

Maintains a clean and controlled internal environment

Suitable for industrial and outdoor applications

Higher efficiency and cooling capacity

Closed-Loop Air Conditioners

5. Open-Loop Air Conditioners

Unlike closed-loop systems, open-loop air conditioners draw air from the outside and circulate it through the enclosure. These units are generally used in environments where contaminants are not a concern, and there’s a need for continuous airflow to remove excess heat.

Key Features:

Continuous air circulation

Less protection against contaminants

Suitable for clean and controlled environments

Typically more cost-effective

6. Dual-Loop Air Conditioners

Dual-loop air conditioners combine the features of both closed-loop and open-loop systems. They utilize two separate loops: one for the internal environment and one for external heat dissipation. This ensures optimal cooling while protecting sensitive equipment from contaminants.

Key Features:

Dual-loop system for enhanced protection and cooling

Suitable for environments with high contamination risks

Efficient in heat dissipation

Versatile for various applications

7. Explosion-Proof Panel Air Conditioners (Panel Air Conditioning Units)

Designed for use in hazardous environments, explosion-proof air conditioners are built to prevent sparks or overheating that could ignite flammable substances. They are heavily used in industries such as oil and gas, chemical processing, and mining.

Key Features:

Explosion-proof design for hazardous environments

Meets safety and regulatory standards

Durable and robust construction

High cooling capacity for large enclosures

8. Water-Cooled Panel Air Conditioners (Panel Air Conditioning Units)

Water-cooled panel air conditioners use water as a cooling medium instead of air. These systems are highly efficient and are used in environments where heat dissipation via air is not sufficient. They are ideal for locations with limited airflow or where heat needs to be transferred away from the immediate area.

Key Features:

Efficient cooling through water circulation

Ideal for environments with limited airflow

Suitable for high heat load applications

Requires water source and plumbing

9. Compact Panel Air Conditioners (Panel Air Conditioning Units)

Compact air conditioners are designed for small enclosures where space is limited. They provide efficient cooling in a smaller footprint, making them ideal for tight spaces or applications where minimal intrusion is required.

Key Features:

Small footprint for tight spaces

Efficient cooling in limited space

Easy installation and maintenance

Suitable for small-scale applications

10. Custom-Built Panel Air Conditioners (Panel Air Conditioning Units)

For specialized applications, custom-built panel air conditioners can be designed to meet specific requirements. These units can be tailored in terms of size, cooling capacity, and features to suit unique industrial needs.

Key Features:

Customizable to specific needs

Tailored cooling capacity and features

Ideal for specialized industrial applications

Designed for unique environmental conditions

Industrial vs. Commercial Panel ACs: Industrial panel air conditioners are built to withstand harsh conditions, such as exposure to dust, moisture, and extreme temperatures. Commercial units, while still robust, are generally used in less demanding environments.

Self-Contained Units: These units house all the necessary components in one enclosure, making them easy to install and maintain.

Split Panel Air Conditioners: In these systems, the evaporator and condenser are housed separately, allowing for greater flexibility in installation and improved cooling efficiency.

Key Features of Panel Air Conditioners (Panel AC Units)

Panel air conditioners are distinguished by several key features that make them suitable for protecting sensitive equipment:

High Cooling Capacity

Despite their size, panel air conditioners are capable of delivering high cooling capacities, ensuring that even densely packed enclosures can be kept cool.

Cytech's Panel Air Conditioners (Panel ACs) Cooling Capacity

DC cabinet air conditioner (DC panel ac)

Model | Voltage | Nominal cooling capacity(W) (L35/L35) | Nominal cooling capacity(Btu/hr) (L35/L35) | Power consumption(W)(L35/L35) | IP Grade | Heater (W)(option) | Internal air flow (m3/h) | Refrigerant | Noise (dbA) |

CYDC105-1 | -48VDC(DC-44~-59V) | 500 | 1700 | 180 | IP55,NEMA 4, NEMA 4X | 500 | 150 | R134a | 60 |

CYDC106-1 | -48VDC(DC-44~-59V) | 600 | 2050 | 200 | IP55,NEMA 4, NEMA 4X | 500 | 150 | R134a | 60 |

CYDC110-1 | -48VDC(DC-44~-59V) | 1000 | 3400 | 295 | IP55,NEMA 4, NEMA 4X | 500 | 450 | R134a | 65 |

CYDC115-1 | -48VDC(DC-44~-59V) | 1500 | 5100 | 495 | IP55,NEMA 4, NEMA 4X | 500 | 450 | R134a | 65 |

CYDC120-1 | -48VDC(DC-44~-59V) | 2000 | 6800 | 710 | IP55,NEMA 4, NEMA 4X | 1000 | 700 | R134a | 69 |

CYDC130-1 | -48VDC(DC-44~-59V) | 3000 | 10200 | 1000 | IP55,NEMA 4, NEMA 4X | 1000 | 900 | R134a | 69 |

CYDC140-1 | -48VDC(DC-44~-59V) | 4000 | 13650 | 1350 | IP55,NEMA 4, NEMA 4X | 1000 | 1100 | R134a | 72 |

AC cabinet air conditioner (AC panel ac)

Model | Voltage | Nominal cooling capacity(W) (L35/L35) | Nominal cooling capacity(Btu/hr) (L35/L35) | Power consumption(W)(L35/L35) | IP Grade | Heater (W)(option) | Internal air flow (m3/h) | Refrigerant | Noise (dbA) |

CYAC103-2 | 220VAC | 300 | 1020 | 170 | IP55,NEMA 4, NEMA 4X | 500 | 100 | R134a | 56 |

CYAC104-2 | 220VAC | 400 | 1360 | 215 | IP55,NEMA 4, NEMA 4X | 500 | 110 | R134a | 56 |

CYAC105-2 | 220VAC | 500 | 1700 | 280 | IP55,NEMA 4, NEMA 4X | 500 | 120 | R134a | 56 |

CYAC110-2 | 220VAC | 1000 | 3400 | 430 | IP55,NEMA 4, NEMA 4X | 1000 | 230 | R134a | 62 |

CYAC112-2 | 220VAC | 1200 | 4080 | 498 | IP55,NEMA 4, NEMA 4X | 1000 | 240 | R134a | 62 |

CYAC113-2 | 220VAC | 1300 | 4440 | 532 | IP55,NEMA 4, NEMA 4X | 1000 | 260 | R134a | 63 |

CYAC115-2 | 220VAC | 1500 | 5100 | 600 | IP55,NEMA 4, NEMA 4X | 1000 | 300 | R134a | 63 |

CYAC120-2 | 220VAC | 2000 | 6800 | 745 | IP55,NEMA 4, NEMA 4X | 1000 | 500 | R134a | 63 |

CYAC125-2 | 220VAC | 2500 | 8500 | 846 | IP55,NEMA 4, NEMA 4X | 2000 | 560 | R134a | 63 |

CYAC130-2 | 220VAC | 3000 | 10200 | 1240 | IP55,NEMA 4, NEMA 4X | 2000 | 720 | R134a | 63 |

CYAC135-2 | 220VAC | 3500 | 11900 | 1360 | IP55,NEMA 4, NEMA 4X | 2000 | 1250 | R134a | 63 |

CYAC150-2 | 220VAC | 5000 | 17000 | 2000 | IP55,NEMA 4, NEMA 4X | 2000 | 2300 | R134a | 63 |

Noise Reduction Technology

Many panel air conditioners are equipped with noise reduction features, ensuring that they do not contribute to a noisy work environment.

Compact Design

One of the standout features of panel air conditioners is their compact design. These units are engineered to fit into confined spaces, making them ideal for use in areas where traditional air conditioners would be impractical. Whether it’s in a tight office space, a small server room, or an industrial control panel, the compactness of these units allows for efficient cooling without sacrificing valuable space.

Energy Efficiency

Panel air conditioners are built with energy efficiency in mind. They use advanced technology to optimize power consumption, often consuming less energy than conventional air conditioning units. This efficiency not only reduces operational costs but also minimizes the environmental impact, making panel air conditioners a smart choice for eco-conscious consumers.

Ease of Installation

Another key feature is the ease of installation. Most panel air conditioners come with a plug-and-play design, allowing for quick and hassle-free setup. Whether you’re a business owner needing to cool an equipment enclosure or a homeowner looking to cool a garage, these units can be installed with minimal effort and downtime. Additionally, their maintenance requirements are relatively low, ensuring long-term reliability.

Durability and Longevity

Panel air conditioners are built to last. Made from robust materials designed to withstand harsh conditions, these units often have a longer lifespan compared to traditional air conditioners. Their durability makes them a cost-effective investment, particularly in industrial settings where reliable performance is crucial.

Temperature Control and Precision

Precision is key in environments where specific temperature ranges must be maintained, and panel air conditioners excel in this area. Equipped with advanced thermostat features, these units offer precise temperature control, ensuring consistent cooling even in the most demanding environments. This is particularly important for protecting sensitive equipment from overheating.

Installation Process

The installation of a panel air conditioner requires careful planning to ensure optimal performance. Pre-installation considerations include determining the correct size and capacity for the enclosure, as well as selecting the most suitable installation location to maximize airflow and efficiency.

Benefits of Using Panel Air Conditioners (Panel AC Units)

Improved Equipment Performance: Prevents overheating, extending the lifespan of sensitive equipment.

Cost-Effectiveness: Reduces long-term costs by minimizing downtime and maintenance.

Space-Saving: Compact design makes them perfect for limited spaces without sacrificing cooling efficiency.

Applications of Panel Air Conditioners (Panel AC Units)

Panel air conditioners are used across various industries:

Industrial Settings: They are commonly used in factories and manufacturing plants where high heat loads are generated.

Commercial Environments: In data centers and server rooms, panel air conditioners play a crucial role in keeping servers and other

equipment cool.

Critical Electronic Equipment Protection: They are essential for protecting sensitive equipment in environments such as telecommunications, medical facilities, and military installations.

Factors to Consider When Choosing a Panel Air Conditioner (Panel AC)

When selecting a panel air conditioner, it’s important to consider several factors:

Cooling Capacity Requirements: Ensure that the unit can handle the heat load of the enclosure.

Energy Efficiency Ratings: Look for units with high energy efficiency ratings to reduce operating costs.

Environmental Conditions: Consider the environment where the unit will be installed, including temperature extremes and exposure to dust or moisture.

Budget Considerations: While it’s important to invest in a quality unit, be sure to choose one that fits within your budget.

Maintenance and Troubleshooting

Regular maintenance is essential for keeping a panel air conditioner operating efficiently. This includes tasks such as cleaning or replacing filters, checking refrigerant levels, and inspecting the unit for any signs of wear or damage.

Environmental Impact

Energy Consumption

Panel air conditioners contribute to global energy consumption, but their efficient design helps minimize this impact. Many units are designed to meet strict energy efficiency standards, reducing their overall environmental footprint.

Refrigerant Use and its Effects

The type of refrigerant used in panel air conditioners also affects their environmental impact. Modern units often use refrigerants with lower Global Warming Potential (GWP), which helps reduce their contribution to climate change.

Choosing a Panel Air Conditioner (Panel AC) from a Leading Panel AC Manufacturer

When looking for a panel AC manufacturer, it’s essential to consider factors such as:

Cooling Capacity: Ensure the unit meets the heat load requirements.

Energy Efficiency: Choose units that consume less energy for long-term savings.

Environment Considerations: Select a unit suitable for the environmental conditions where it will be installed.

Budget: While high-quality systems might cost more initially, the long-term savings and reliability make them a worthwhile investment.

Future Trends in Panel Air Conditioners (Panel AC Units)

The future of panel AC manufacturers lies in integrating smarter technologies, such as remote monitoring and smart thermostats, to enhance user experience and energy efficiency. The market is expected to grow as industries increasingly rely on these systems to protect their valuable equipment.

Comparison with Other Cooling Solutions

Panel air conditioners offer several advantages over other cooling solutions, such as traditional air conditioning units and portable air conditioners, particularly in terms of their ability to provide targeted cooling for enclosures.

Leading Brands and Models

When it comes to choosing a panel air conditioner, it’s important to consider models from leading manufacturers, which are known for their reliability and performance. Popular brands include Rittal, Schneider Electric, Pfannenberg and Cytech, each offering a range of models with varying features to suit different needs.

Cost Analysis and Budgeting

While the initial cost of a panel air conditioner may be high, it’s important to consider the long-term savings in terms of reduced equipment downtime and maintenance costs.

FAQs About Panel Air Conditioners (Panel Air Conditioning Units)

How do panel air conditioners (panel air conditioning units) differ from traditional units?

Panel air conditioners are designed specifically for cooling enclosures that house sensitive equipment, whereas traditional units are meant for living spaces.

Are panel ACs energy-efficient?

Yes, modern panel air conditioners are equipped with energy-saving technologies that make them highly efficient.

What is the lifespan of a panel air conditioner (panel ac)?

With proper maintenance, a panel air conditioner can last for many years, often 10-15 years or more.

How much maintenance do they require?

Regular maintenance, including cleaning filters and checking refrigerant levels, is essential to ensure efficient operation.

Can panel air conditioners be used in residential settings?

While they are designed for industrial and commercial use, panel air conditioners can be used in residential settings where specific

equipment needs cooling.

What are the best panel AC manufacturers?

Popular manufacturers include Rittal, Schneider Electric, Pfannenberg, and Cytech known for their quality and reliability.