Effectively managing heat is crucial for a wide range of industries, particularly where electrical and industrial systems generate significant waste heat. Among the various methods to tackle this challenge, thermosyphon technology stands out as an innovative, eco-friendly solution. Thermosyphons combine phase-change cooling principles with gravity to create an efficient, closed-loop system for thermal management. This article provides a detailed look at how thermosyphons work, their integration with heat exchangers, and the many advantages they offer.

Understanding Thermosyphons and Heat Exchangers

What Are Heat Exchangers (HEXs)?

Heat exchangers are systems designed to transfer heat between two or more fluids without mixing them. Common in industries like HVAC, power generation, and electronics cooling, heat exchangers optimize energy use by recycling or dissipating thermal energy.

What Are Thermosyphons?

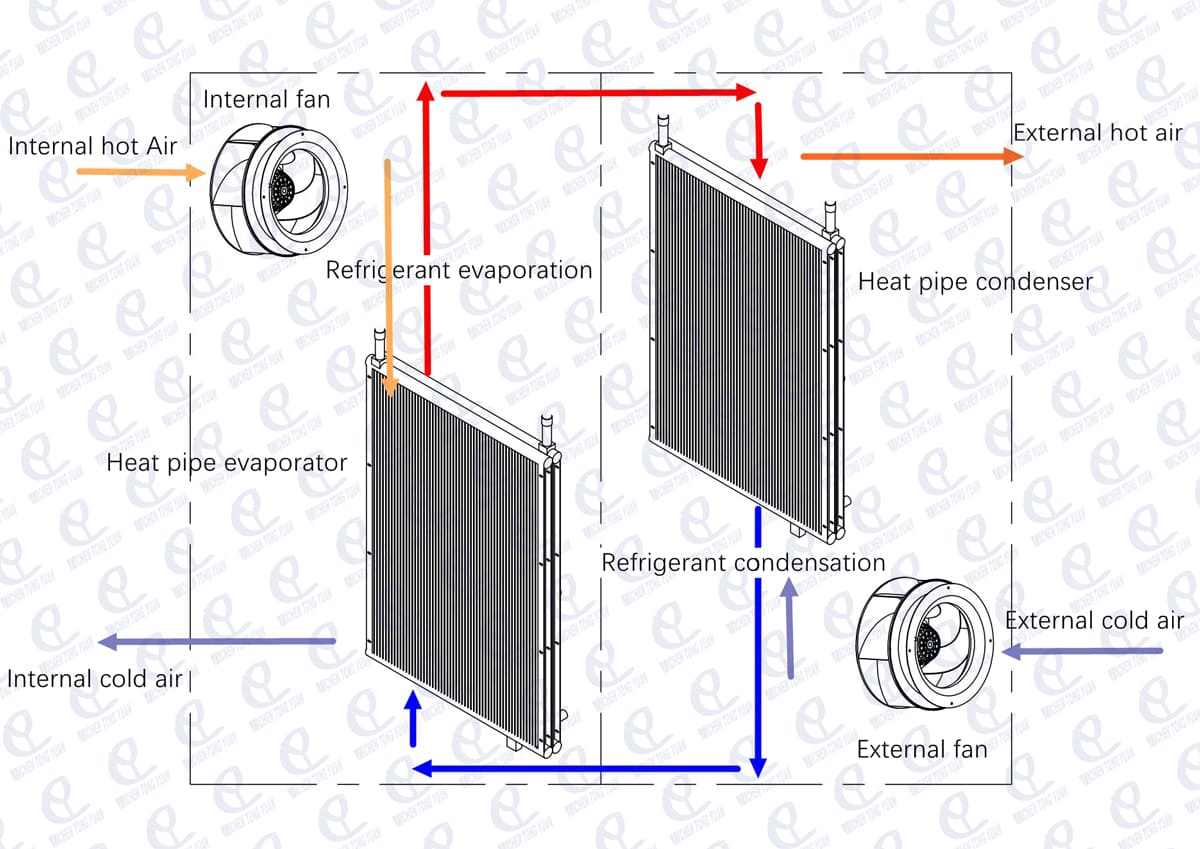

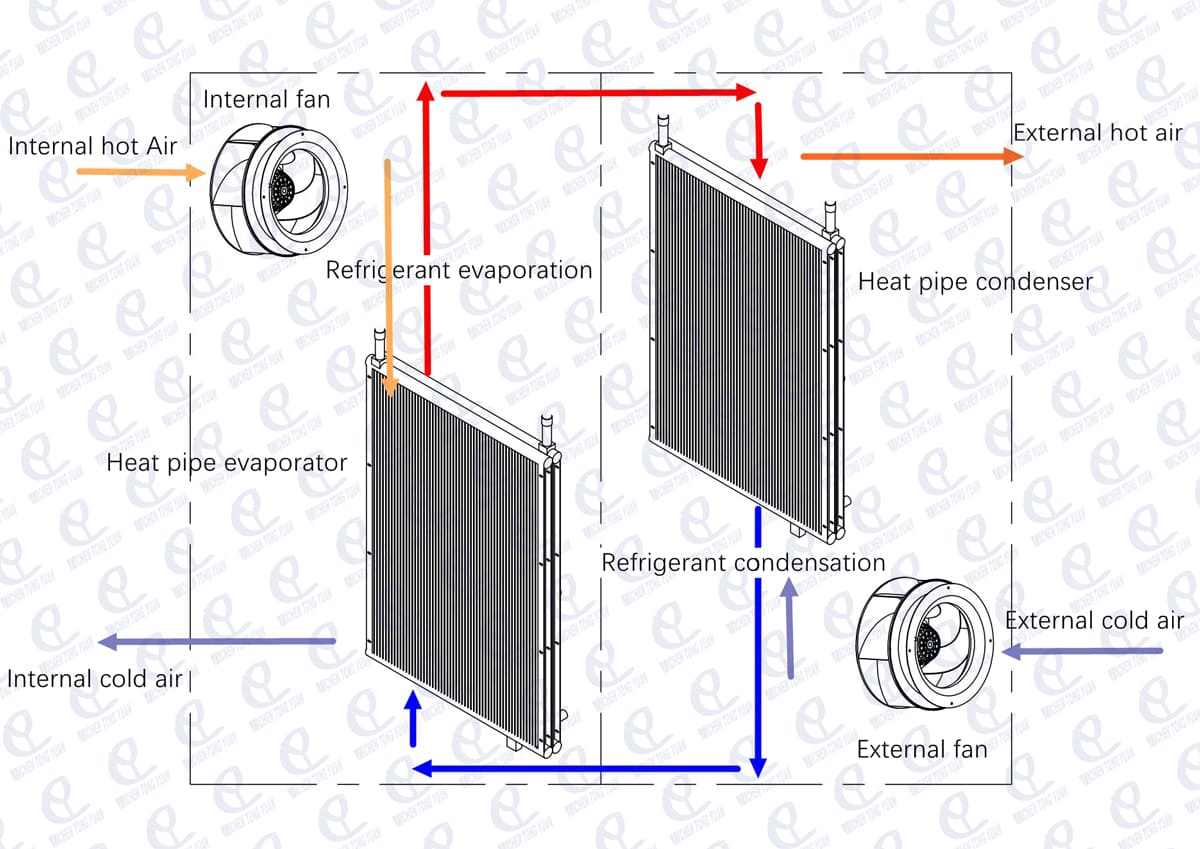

Thermosyphons are passive heat transfer devices that rely on the principles of phase-change cooling and gravity. They function without mechanical pumps, making them both efficient and reliable. The technology features three main components:

Evaporator Section: Absorbs heat and vaporizes the working fluid.

Adiabatic Section: Transports vapor with minimal heat loss.

Condenser Section: Releases heat and condenses vapor back into liquid.

The Science Behind Thermosyphon Heat Transfer

1. Phase-Change Cooling

At the heart of thermosyphon functionality is phase-change cooling, a process where a fluid absorbs or releases latent heat during evaporation and condensation:

Heat Absorption and Vaporization: The working fluid in the thermosyphon's evaporator section absorbs heat from the source. As it heats up, the fluid vaporizes, transitioning from liquid to vapor. This process occurs without a significant rise in temperature due to the fluid's latent heat of vaporization.

Heat Transport: The vaporized fluid rises through the adiabatic section, where it is transported to the condenser without significant thermal loss.

Condensation and Heat Release: At the condenser section, the vapor releases its absorbed heat to the surroundings or a cooling medium (e.g., air or water). This loss of energy causes the vapor to condense back into liquid form.

Gravity-Driven Return: The denser liquid flows back to the evaporator under the influence of gravity, completing the cycle.

2. Natural Convection and Gravity

Thermosyphons rely on natural convection currents to transport heat. The difference in density between the vapor and liquid phases, combined with gravity, ensures continuous circulation of the working fluid. This passive mechanism eliminates the need for mechanical circulation, reducing energy consumption and maintenance requirements.

3. Latent Heat Advantage

The utilization of latent heat during phase changes allows thermosyphons to transfer large quantities of heat with minimal temperature gradients, enhancing their efficiency compared to conventional conduction or convection-based systems.

Phase-Change Cooling: The Core Principle

Thermosyphons rely on phase-change cooling, which utilizes the latent heat of vaporization to transfer heat. This process involves:

Heat Absorption: The liquid working fluid in the evaporator absorbs heat from the heat source, such as electrical components or industrial machinery.

Evaporation: Upon absorbing sufficient heat, the liquid evaporates, transitioning into vapor without a significant temperature increase.

Heat Release: The vapor travels to the condenser, where it releases heat to the surroundings or a secondary fluid. This causes the vapor to condense back into liquid.

Gravity-Driven Return: The liquid flows back to the evaporator via gravity, restarting the cycle.

This self-sustaining system continues as long as waste heat is present, making thermosyphons highly efficient and reliable.

How Heat Exchangers (HEXs) Utilize Thermosyphons

Thermosyphons enhance the performance of heat exchangers by leveraging their ability to handle high heat loads with minimal energy input. Key features include:

1. Efficient Heat Transfer

Thermosyphons efficiently transfer heat using natural convection and gravity. The absence of moving parts eliminates energy-intensive components like pumps, reducing operational energy consumption.

2. Closed-Loop Design

The working fluid operates within a sealed system, ensuring no leaks or losses over time. This eliminates the need for regular refilling or maintenance.

3. Versatile Applications

Thermosyphon heat exchangers are used across industries for tasks such as cooling electrical systems, recovering industrial waste heat, and enhancing the efficiency of renewable energy systems.

Benefits of Thermosyphons in Heat Exchangers (HEXs)

Thermosyphon-based heat exchangers provide several unique advantages:

Energy Efficiency

By eliminating external power sources for fluid circulation, thermosyphons significantly reduce energy consumption. This makes them cost-effective and environmentally friendly.

Low Maintenance Requirements

The closed-loop design minimizes wear and tear, reducing the need for scheduled maintenance or unexpected repairs. This ensures continuous operation with minimal downtime.

Reliable Operation

Thermosyphons function effectively under a wide range of operating conditions. Their passive nature ensures reliability even in remote or demanding environments.

Eco-Friendly

With no moving parts and an optimized thermal cycle, thermosyphons have a smaller carbon footprint compared to conventional cooling systems.

Compact Design

The absence of mechanical components allows for a lightweight and compact design, enabling easy integration into existing systems.

Applications of Thermosyphon Technology

Thermosyphon heat exchangers find use in numerous industries, including:

1. Industrial Heat Recovery Systems

Thermosyphons capture and recycle waste heat from industrial processes, reducing energy wastage and operating costs.

2. Electronics Cooling

In data centers and electronics, thermosyphons effectively dissipate heat, maintaining optimal operating temperatures and preventing overheating.

3. HVAC Systems

Thermosyphon technology enhances the efficiency of HVAC systems by improving heat exchange processes in heating and cooling applications.

4. Renewable Energy

Thermosyphons are integral to solar thermal systems and geothermal energy setups, where efficient heat management is critical.

Design Considerations for Thermosyphon Heat Exchangers (Thermosyphon HEXs)

Creating a highly efficient thermosyphon-based heat exchanger (Thermosyphon HEX) involves attention to several design factors:

Material Selection: Use materials with high thermal conductivity and resistance to corrosion for durability.

Working Fluid Compatibility: Select fluids that match the system’s operating temperature range to maximize efficiency.

Orientation: Ensure proper alignment for gravity-driven fluid circulation.

Efficiency Enhancements: Incorporate fins or advanced coatings to improve heat transfer rates.

Challenges and Innovations in Thermosyphon Technology

Challenges

Despite their advantages, thermosyphons face limitations such as sensitivity to orientation (gravity-dependent operation) and reduced effectiveness in low-temperature gradients.

Innovations

Recent advancements aim to overcome these challenges:

Nanotechnology in Working Fluids: Enhanced thermal properties through nanofluids.

Smart Monitoring Systems: IoT-enabled sensors for real-time performance tracking.

Advanced Materials: Improved durability and heat transfer through innovative alloys.

Frequently Asked Questions

1. What is the primary benefit of thermosyphons in heat exchangers?

Thermosyphons provide efficient, passive heat transfer with minimal energy consumption.

2. How does the working fluid in a thermosyphon contribute to heat transfer?

The fluid absorbs heat during evaporation and releases it during condensation, driving the heat transfer process.

3. Are thermosyphon systems suitable for all heat exchangers?

Yes, but they are most effective in systems where gravity can facilitate fluid circulation.

4. Do thermosyphons require maintenance?

Their closed-loop design minimizes maintenance needs, as no refilling or moving parts are involved.

5. What industries benefit the most from thermosyphon technology?

Industries like electronics, HVAC, renewable energy, and manufacturing benefit significantly from thermosyphon-based heat exchangers.

Conclusion

Thermosyphons have revolutionized heat exchanger technology, offering an eco-friendly, efficient, and reliable solution to thermal management challenges. Their wide-ranging applications across industries highlight their importance in modern engineering. By leveraging phase-change cooling and gravity, thermosyphons provide an innovative approach to optimizing energy use and reducing environmental impact.