Advantages of Air-to-Air Enclosure Heat Exchanger: A Deep Dive into Efficient Cooling Solutions

As experts in the air conditioning industry, we recognize the growing importance of optimizing temperature regulation in electrical and electronic equipment enclosures. The Air-to-Air Enclosure Heat Exchanger provides an innovative, energy-efficient solution, addressing the unique cooling challenges faced by these sensitive environments. Here's a closer look at the key advantages of using an Air-to-Air Enclosure Heat Exchanger:

1. Efficient Heat Dissipation

The Air-to-Air Enclosure Heat Exchanger excels in dissipating the heat generated by internal electronic components. By transferring excess heat to the ambient air outside the enclosure, it ensures that the internal environment remains at optimal operating temperatures, preventing overheating and maintaining the performance and longevity of the equipment.

2. Energy Efficiency

Compared to traditional air conditioning systems, Air-to-Air Enclosure Heat Exchanger offers superior energy efficiency. These systems are designed to operate only when needed, adjusting their cooling response based on real-time internal temperature changes. This dynamic operation leads to reduced energy consumption, providing cost savings and promoting sustainability in the long term.

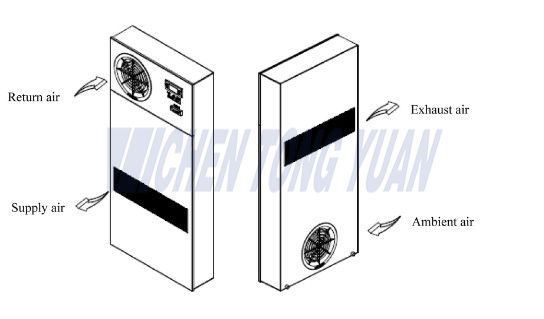

3. Compact Design

One of the standout features of the Air-to-Air Enclosure Heat Exchanger is its compact design. These units are specifically engineered to fit within the constrained space of electrical enclosures, allowing for seamless integration into various cabinets. This space-saving design is ideal for applications where maximizing internal space is critical, without compromising on cooling effectiveness.

4. Closed System Protection

The Air-to-Air Enclosure Heat Exchanger offers vital protection to sensitive electronic components by maintaining a sealed, controlled environment. This is crucial for preventing contaminants, dust, and other external elements from entering the enclosure, which could potentially compromise the functionality and reliability of the equipment. The closed-loop system creates a barrier, ensuring the integrity of your electronics.

5. Low Maintenance Requirements

Another significant advantage of Air-to-Air Enclosure Heat Exchanger is their low maintenance needs. Unlike traditional air conditioning systems, which require regular servicing and component replacements, these heat exchangers are designed to operate with minimal upkeep. This results in fewer maintenance-related disruptions, reduced downtime, and long-term operational cost savings.

6. Adaptability to Harsh Environments

The robustness of the Air-to-Air Enclosure Heat Exchanger makes it suitable for a wide range of environmental conditions, including harsh industrial settings. Whether it's dealing with high dust levels, extreme temperatures, or other challenging factors, these heat exchangers are built to maintain consistent cooling performance, ensuring equipment reliability in even the most demanding environments.

7. Quiet Operation

Unlike many traditional cooling systems, Air-to-Air Enclosure Heat Exchanger operates quietly, making them perfect for applications where noise reduction is a priority. Whether in offices, control rooms, or other noise-sensitive environments, these heat exchangers maintain a low decibel level while effectively managing heat dissipation.

Conclusion

The Air-to-Air Enclosure Heat Exchanger is a highly efficient, adaptable, and low-maintenance cooling solution for electronic equipment. Its energy-saving design, compact nature, and protection capabilities make it an invaluable asset in ensuring the longevity and optimal performance of sensitive components. Whether in industrial or office settings, the Air-to-Air Enclosure Heat Exchanger represents a forward-thinking approach to maintaining temperature regulation in enclosures.