The Cytech 120W/K air-to-air enclosure heat exchanger is engineered to deliver efficient, closed-loop cooling for outdoor telecom cabinets, power distribution boxes, battery energy storage systems (BESS), and industrial control panels. With a compact panel-mounted design and IP-rated protection, it ensures stable cabinet temperatures while preventing dust, moisture, and contaminants from entering the enclosure.

Designed for long operating life and maintenance-free performance, this 120W/K model is ideal for harsh outdoor environments where reliability is critical.

Download datasheet of 120w/k Enclosure heat exchanger

120wk enclosure heat exchanger datasheet .pdf

120wk enclosure heat exchanger datasheet .pdf

Application Case of plate enclousre heat exchanger

Key Features of the 120W/K Enclosure Heat Exchanger

◆High Cooling Efficiency (120W/K Performance)

The unit delivers 120 watts per kelvin of thermal transfer capacity, helping maintain a safe internal temperature even when outdoor ambient heat fluctuates.

◆Closed-Loop, Contamination-Free Cooling

Air inside the cabinet is completely isolated from the outdoor environment.

This prevents:

dust

humidity

sand

corrosive gases

A perfect solution for sensitive telecom and electrical electronics.

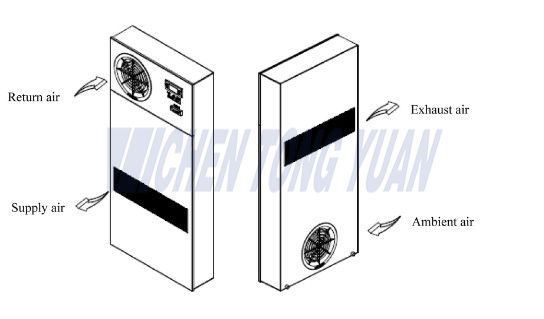

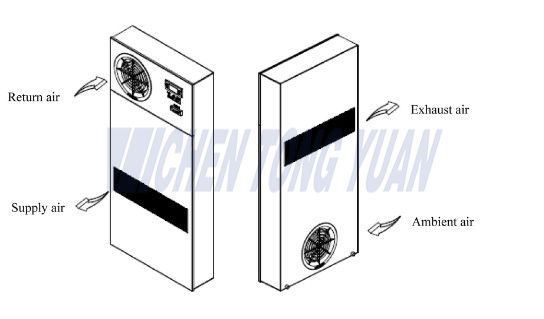

◆Panel-Mounted, Space-Saving Design

The slim profile allows flexible installation on:

◆Maintenance-Free Operation

No filters are required, and no refrigerants are used.

The system runs quietly with low energy consumption and minimal service needs.

◆Built for Harsh Outdoor Environments

With IP-rated protection and corrosion-resistant materials, the heat exchanger withstands:

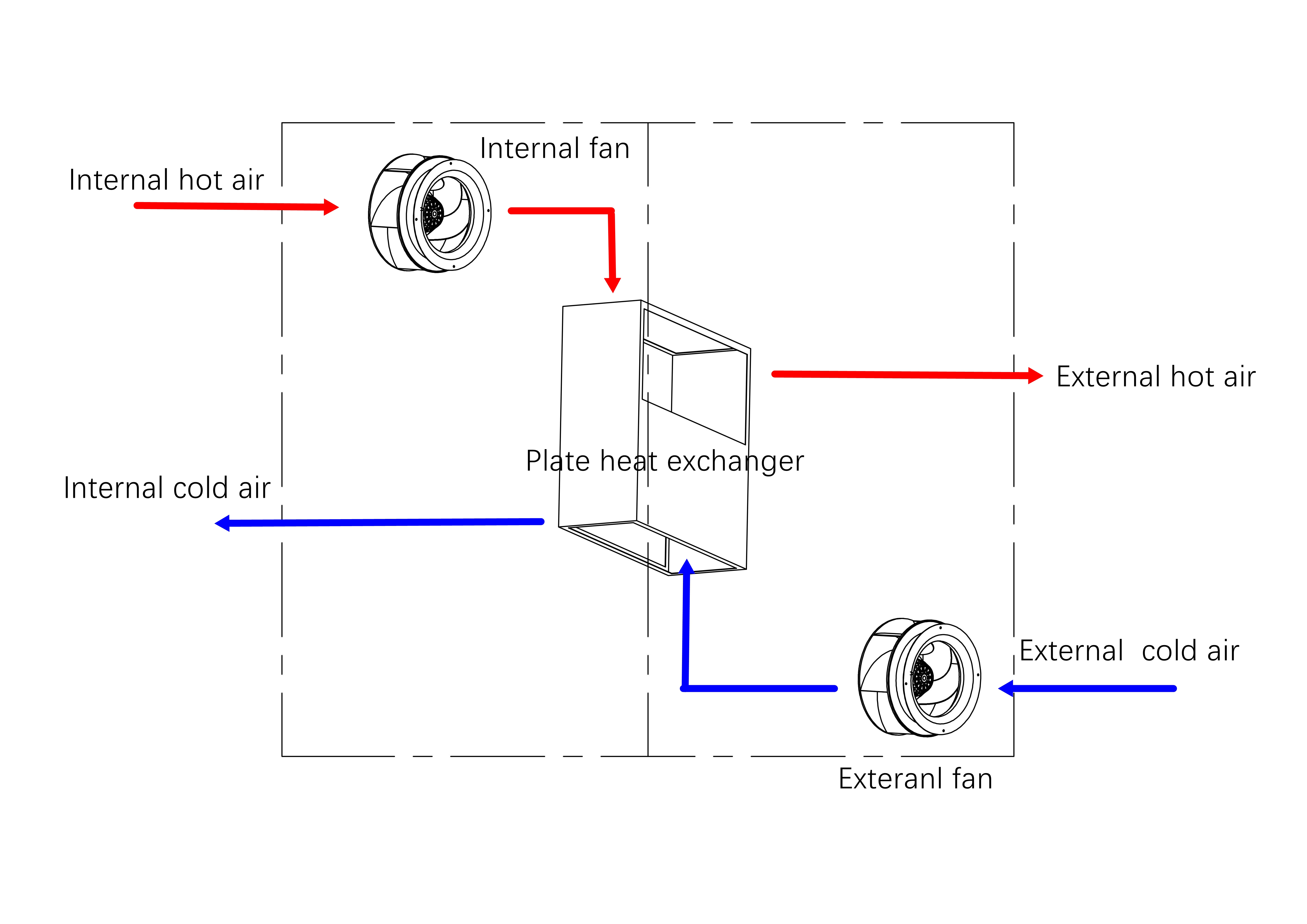

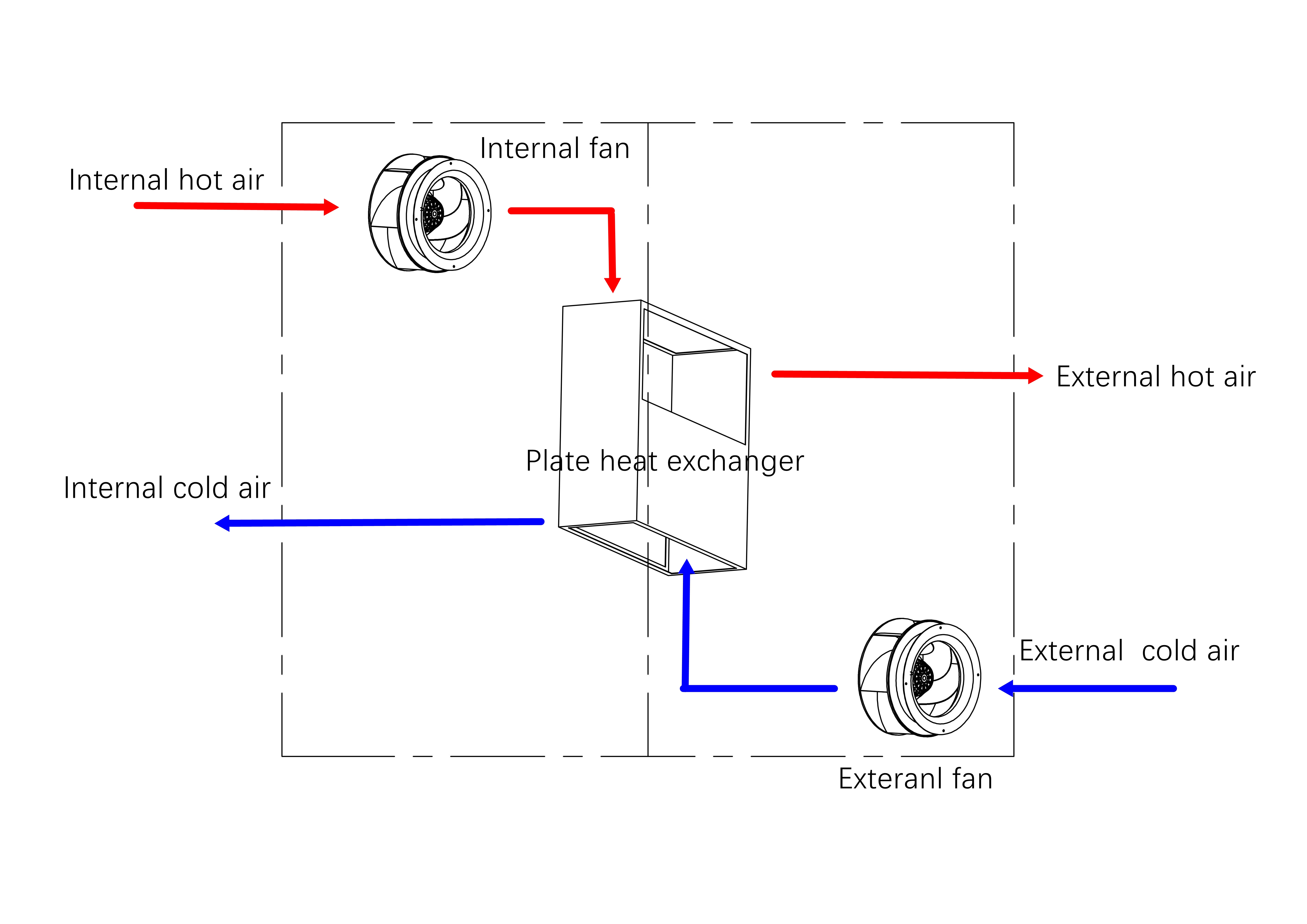

Airflow of 120w/k Enclosure Heat Exchanger

An air/air counter-current plate heat exchanger is used to transfer the heat. Two centrifuge fans, one for the internal circuit and one for the external circuit provide ventilation.

The enclosure heat exchanger module is designed in such a way that the speed of the external circuit fan is controlled according to temperature, based on the pre-set pattern.

120W/K Enclosure Heat Exchanger Technical Specification

| Name | Enclosure Heat Exchanger |

| Cooling Type | Air-to-Air, Closed Loop |

Model | H12NA0E |

| Material | Galvanized steel/ss304/aluminium |

Main power supply | 48VDC±20% (AC/DC options) |

Cooling capacity(rated) | 120W/K |

Power consumption(rated) | 180W |

Heating(Optional) | 1000W(Powered By AC) |

Current (Cooling) | 4.0A |

Operation Temp. Range | -40℃~+60℃ |

Internal circulating airflow | 620m³/h |

| Mounting method | Panel Mounted |

Max noise | 69dB(A),Low-noise axial fans |

IP level | IP55 |

Net weight | 32Kg |