Key Features

260wk heat exchanger datasheet.pdf

260wk heat exchanger datasheet.pdf

Energy-Efficient Closed-Loop Cooling

Transfers heat using a counter-current plate heat exchanger, without mixing internal & external air.

Maintains cabinet protection while ensuring effective heat dissipation.

Ideal replacement for traditional enclosure air conditioners to reduce energy consumption.

Designed for Harsh Outdoor Environments

External and internal fans feature IP55/IP65/NEMA 4/4X protection, preventing dust, water, and debris ingress.

Suitable for telecom towers, roadside cabinets, renewable energy systems, railway cabinets, and more.

Stable Performance Across Extreme Temperatures

Operates efficiently in –40°C to +60°C outdoor conditions.

Suitable for desert, coastal, tropical, and high-altitude installation sites.

Low Maintenance & Long Lifespan

Intelligent Fan Speed Control

External fan automatically adjusts speed based on cabinet temperature.

Reduces power consumption and noise during low heat loads.

Ensures efficient cooling when internal temperature rises.

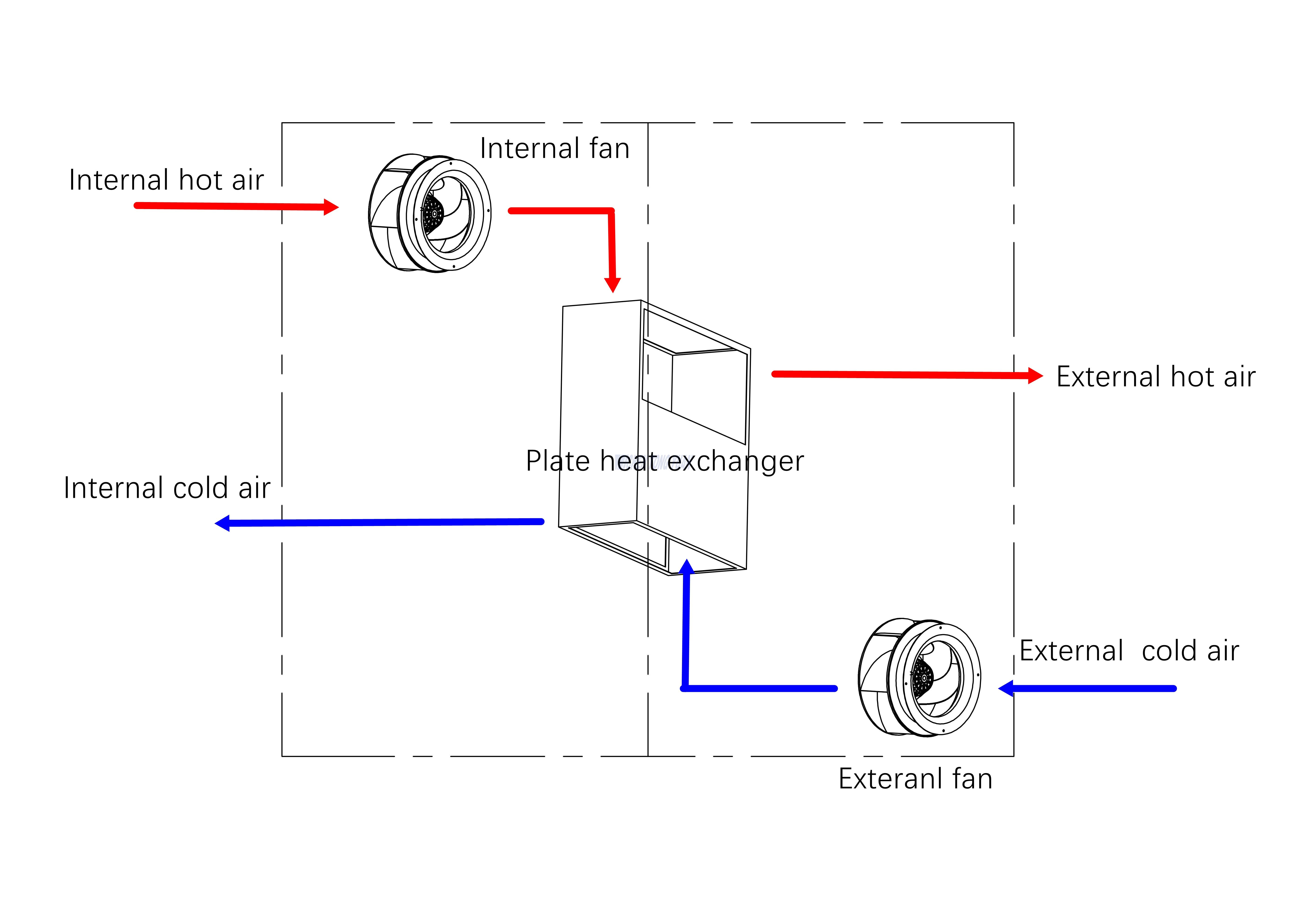

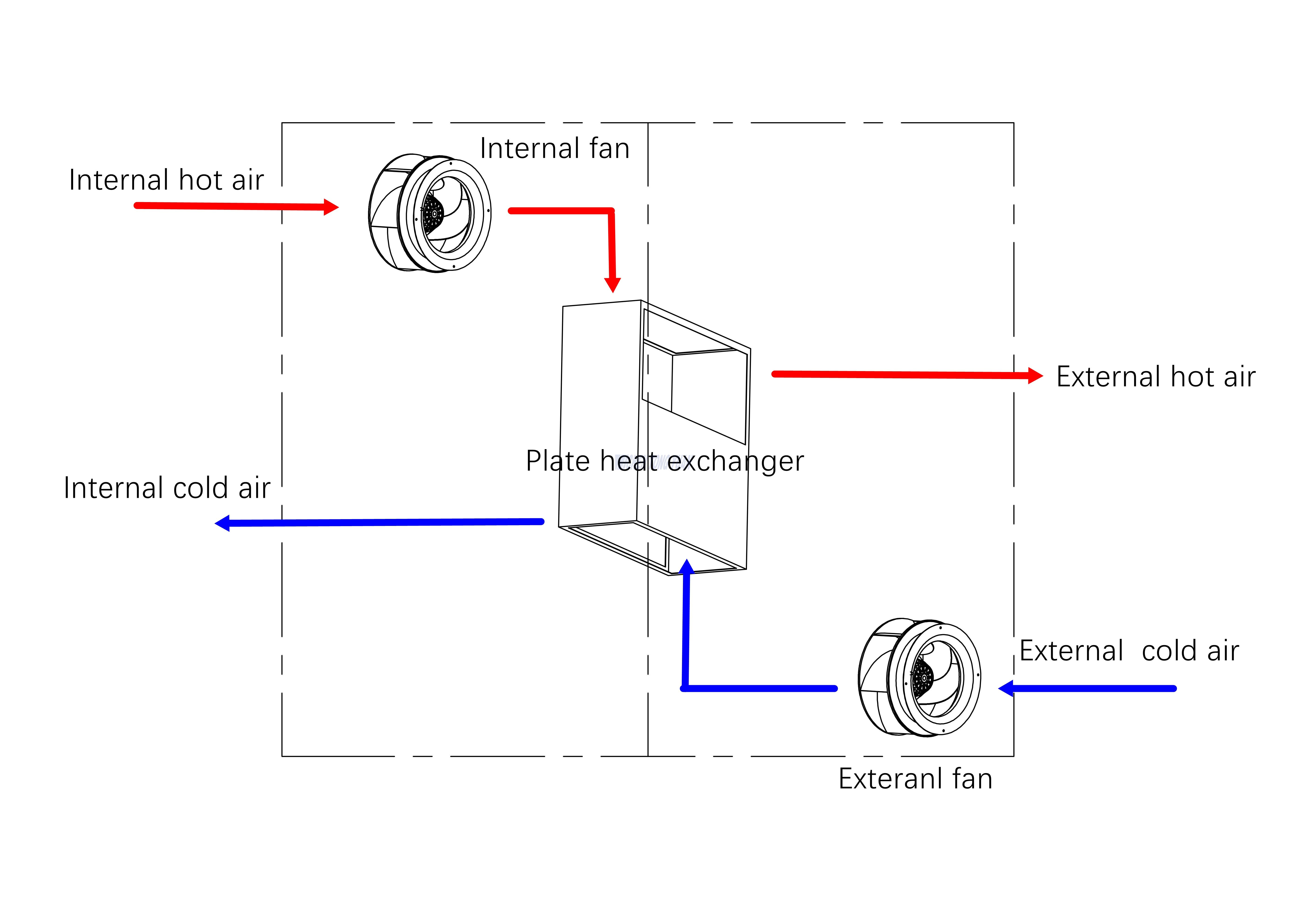

How the Air-to-Air Heat Exchanger Works

Closed-Loop, Dual-Fan Structure

◆Internal Circulation Fan:

Continuously draws warm air from inside the cabinet and passes it through the heat exchanger core.

◆External Ambient Fan:

Pulls outside air through the external channel to absorb heat and reject it into the environment.

◆Counter-Current Plate Heat Exchanger Core:

High-efficiency plate design

Two separated air pathways

Heat transfers through the aluminum plates

Internal airflow never contacts outdoor air, protecting sensitive electronics

Smart Temperature Regulation

As cabinet temperature increases → fan speed increases

As temperature decreases → fan slows down to save energy

This ensures:

Thermal cycle and air flowing

260W/K Enclosure Air-to-Air Heat Exchanger Technical Specification

| Name | Enclosure Air to Air Heat Exchanger |

Model | H26NA0E |

Main power supply | 48VDC±20% |

Cooling capacity(rated) | 260W/K |

Power consumption(rated) | 400W |

Heating(Optional) | 1000W(Powered By AC) |

Current (Cooling) | 4.0A |

Operation Temp. Range | -40℃~+60℃ |

Internal circulating airflow | 1650m³/h |

Max noise | 70dB(A) |

IP level | IP55, IP65, NEMA 4, NEMA 4X |

| Working Principle | Counter-current plate heat exchanger + dual fans |

| Installation | Door-mounted / side-mounted |

Net weight | 65Kg |

Optional customized voltage, airflow, and installation sizes available.