High-Efficiency 220W/K Heat Pipe Cabinet Cooling Solution

The 220W/K heat pipe enclosure heat exchanger is engineered for stable and energy-efficient thermal management in outdoor telecom cabinets, power distribution enclosures, industrial control panels, battery cabinets, and communication base stations.

Using advanced passive heat pipe technology, the system delivers reliable heat transfer performance with low power consumption, long lifecycle, and minimal maintenance.

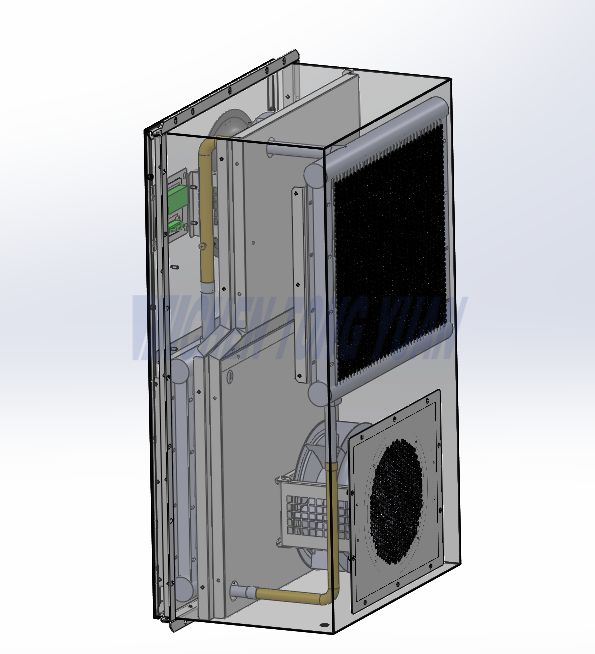

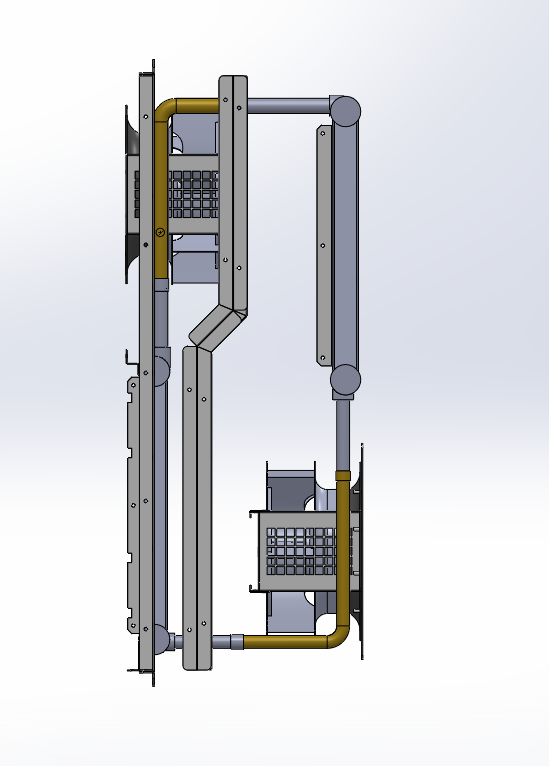

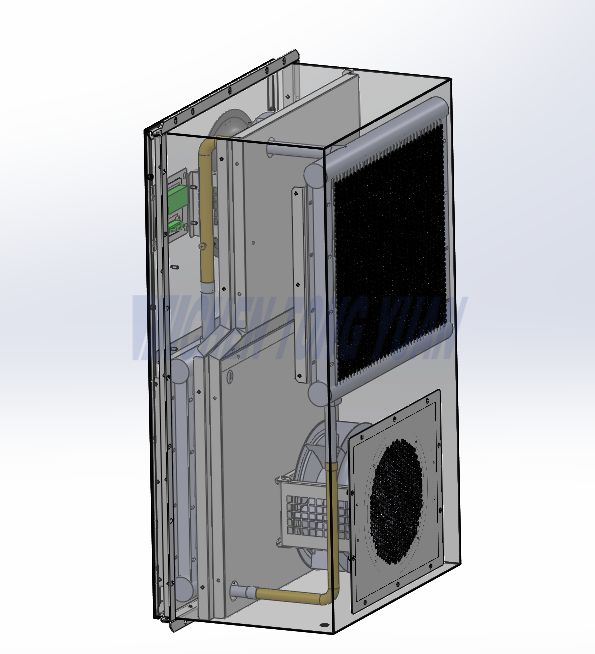

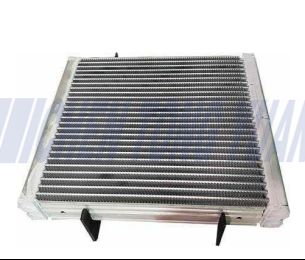

▼heat pipe cross section 3D view ▼

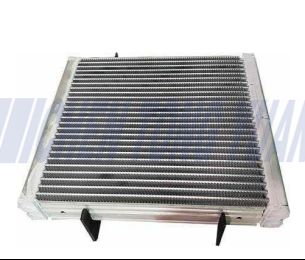

There is no compressor,but heat pipe with Microchannel heat exchange core

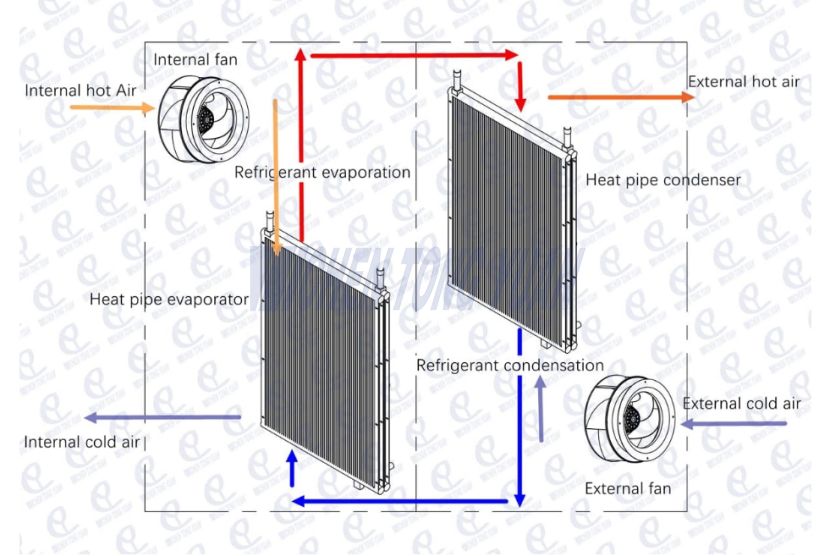

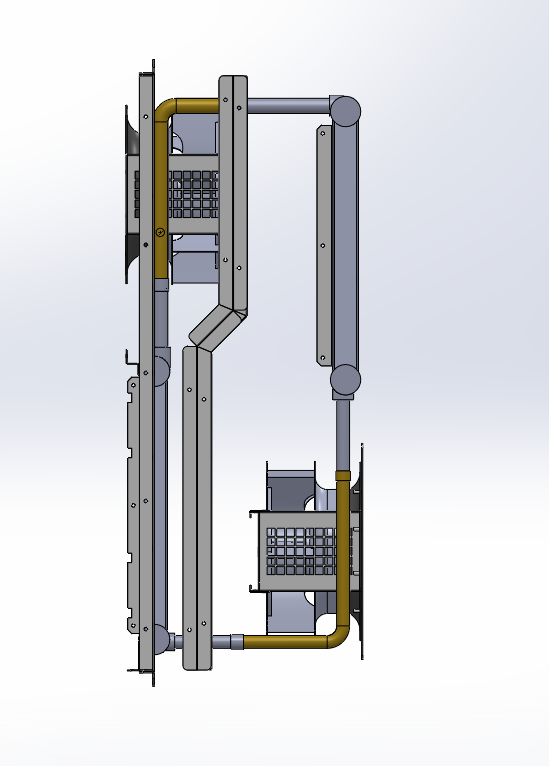

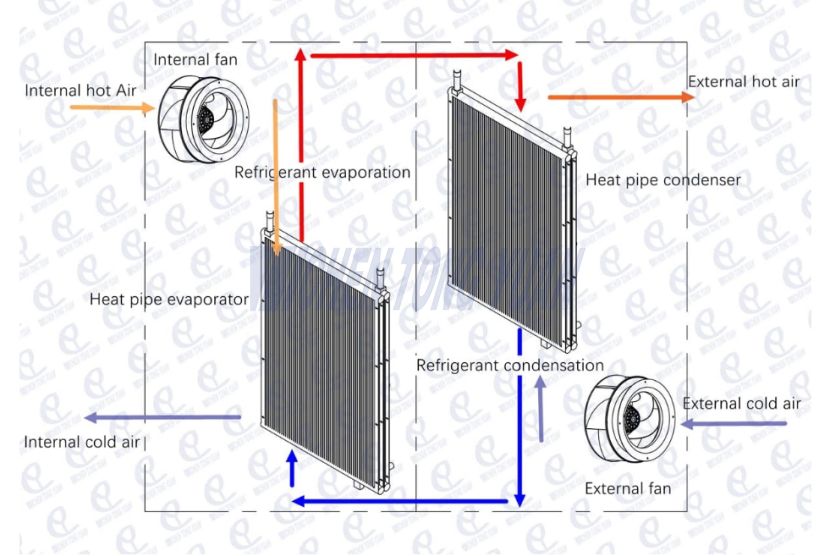

220W/K Heat Piple Electrical Enclosure Heat Exchanger Thermal cycle and air flowing diagram

The waste heat generated from the internal equipment will be absorbed by the refrigerant

through the evaporator and dissipate to the ambient by the condenser of external side.

Why Choose the 220W/K Heat Pipe Heat Exchanger

Closed-Loop Cooling for Harsh Outdoor Environments

Prevents dust, moisture, oil mist, salt spray, and corrosive pollutants from entering the cabinet

Ideal for IP65 outdoor telecom cabinets and roadside enclosures

High Thermal Performance (220W/K)

Energy-Saving & Long Service Life

Ultra-low energy consumption

Very low failure rate due to passive heat transfer mechanism

Minimal maintenance required

Wide Operating Temperature Range

Easy Installation & Integration

220W/K Heat Pipe Enclosure Heat Exchanger – Core Parameters

Model | H22NA0E / H22HA0E |

Main power supply | 48VDC±20%,220V AC (options) |

Cooling capacity(rated) | 220W/K |

Power consumption(rated) | 180W Ultra-low (passive heat transfer) |

Heating(Optional) | 500W(Powered By AC) |

Current (Cooling) | 3.75A/4.1A |

Operation Temp. Range | -40℃~+65℃ |

Max noise | 69dB(A) |

Communication

| Rs485 option |

| Installation | panel mounted/door mounted |

Alarm output

| Dry contact |

IP level | IP65 |

Net weight | 30Kg |

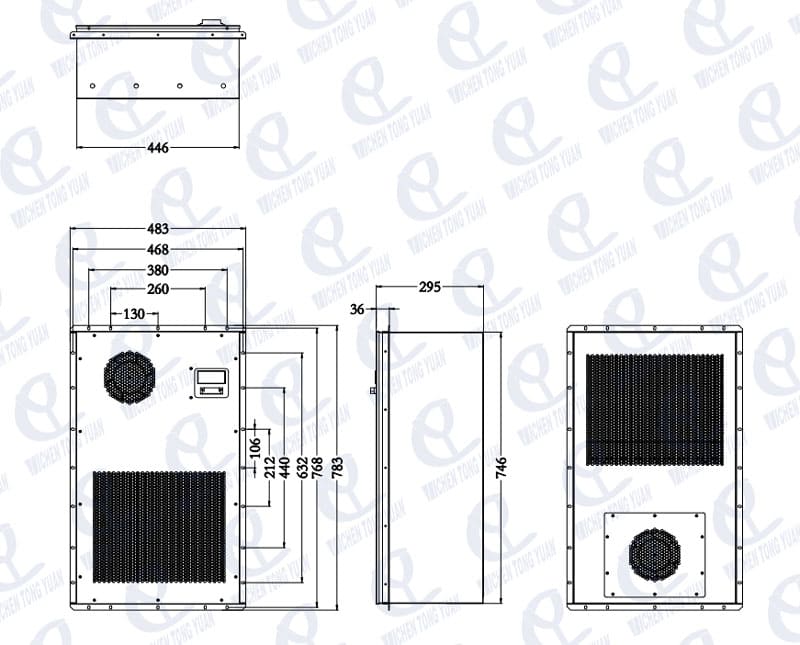

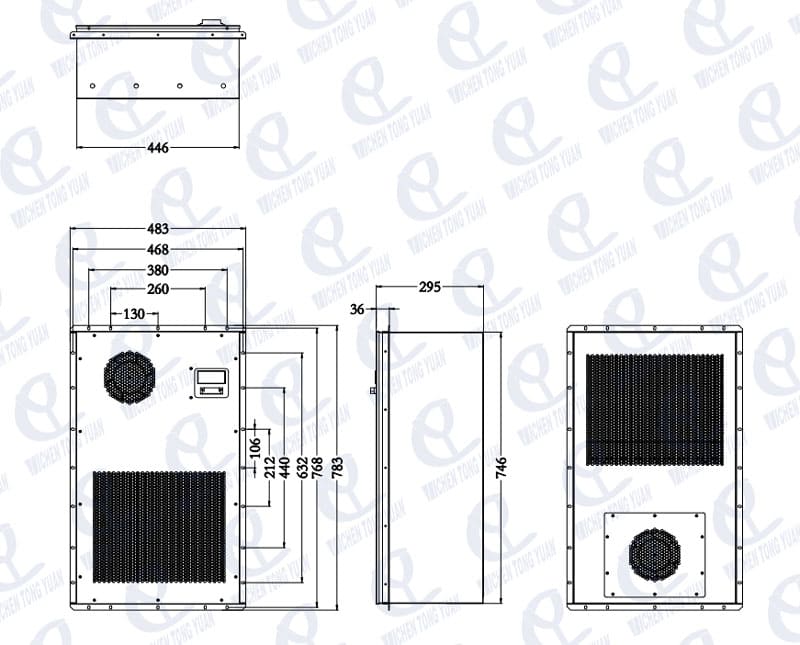

220W/K Electrical Enclosure Heat Exchanger Outer Dimension

220W/K Electrical Enclosure Heat Exchanger Installation and wiring

220W/K Electrical Enclosure Heat Exchanger Wiring

Equipped with a display LED in internal side of product, can display running, alarm information and parameter

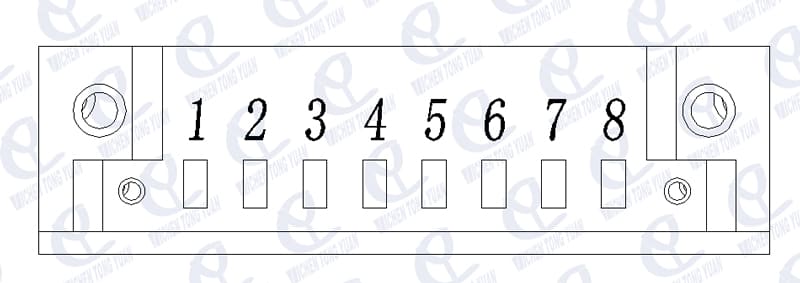

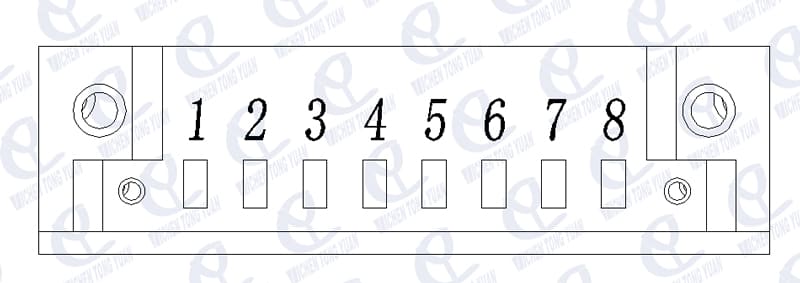

220W/K Electrical Enclosure Heat Exchanger Definition of electrical terminal

Symbol | Definition | Symbol | Definition |

ALR-NO | Alarm output-NO | PE | Grounding wire |

ALR-COM | Alarm output-COM | - | DC power- Negative |

ALR-NC | Alarm output-NC | + | DC power- Positive |

RS485- | Communication port B- |

|

|

RS485+ | Communication port A+ |

|

|