80W/K Cabinet Heat ExchangerIntroduction

Cabinet heat exchanger, also known as cabinet cooler, is a device designed to regulate the temperature inside the casing of electrical or electronic equipment through a heat exchanger.

The main function of a cabinet type heat exchanger is to dissipate the heat generated inside the casing into the surrounding environment. This is achieved through a heat exchange process, which involves transferring heat from the internal air to the external medium, usually air or water.

Working Principle of 80W/K Cabinet Heat Exchanger

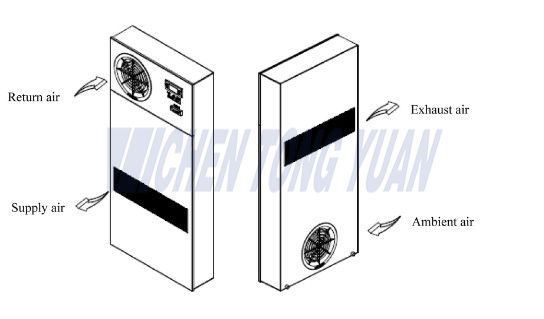

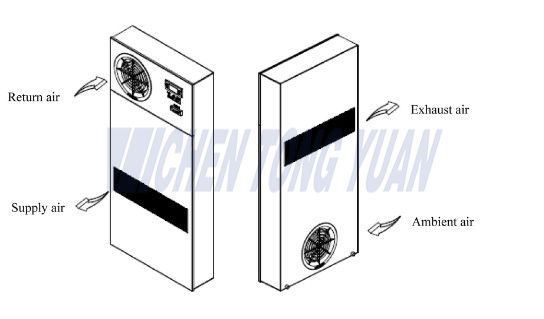

Cabinet heat exchanger is mostly used for enclosed area cooling, CYTECH series is designed especially for mounting in a cabinet. The unit uses ambient air for temperature regulation so it must have access to ambient. The internal temperature of the enclosure is cooled via effective utilization of the ambient air. An air/air counter-current plate heat exchanger is used to transfer the heat. Two centrifuge fans, one for the internal circuit and one for the external circuit provide ventilation.

The cabinet heat exchanger module is designed in such a way that the speed of the external circuit fan is controlled according to temperature, based on the pre-set pattern.

80W/K Cabinet heat exchanger specification parameter

Model | H08NA0E |

Main power supply | 48VDC±20% |

Cooling capacity(rated) | 80W/K |

Power consumption(rated) | 70W |

Heating(Optional) | 1000W(Powered By AC) |

Current (Cooling) | 1.5A |

Operation Temp. Range | -40℃~+60℃ |

Internal circulating airflow | 470m³/h |

Max noise | 65dB(A) |

IP level | IP55 |

Net weight | 17Kg |

More option for cabinet heat exchanger

| Name | Model | Voltage | Cooling capacity(rated)(W/K) | Power consumption(W) | IP Grade | Heater (W)(option) | Internal air flow (m3/h) | Weight(KG) | Noise (dbA) |

| Cabinet Heat Exchanger | H08NA0E | 48VDC±20% | 80 | 70 | IP55,NEMA 4, NEMA 4X | 1000 | 470 | 17 | 65 |

| Cabinet Heat Exchanger | H12NA0E | 48VDC±20% | 120 | 180 | IP55,NEMA 4, NEMA 4X | 1000 | 620 | 32 | 69 |

| Cabinet Heat Exchanger | H18NA0E | 48VDC±20% | 180 | 330 | IP55,NEMA 4, NEMA 4X | 1000 | 980 | 45 | 69 |

| Cabinet Heat Exchanger | H26NA0E | 48VDC±20% | 260 | 400 | IP55,NEMA 4, NEMA 4X | 1000 | 1650 | 65 | 70 |

Advantages of cabinet heat exchanger

Cabinet heat exchanger offers several advantages in managing the temperature within electrical or electronic equipment enclosures:

◆Efficient Heat Dissipation:

Cabinet heat exchanger efficiently dissipate heat generated by electronic components, preventing overheating and ensuring optimal operating temperatures.

◆Energy Efficiency:

Compared to traditional air conditioning systems, cabinet heat exchangers is often more energy-efficient. They only operate when necessary, responding to changes in internal temperatures, which can result in lower overall energy consumption.

◆Compact Design:

Cabinet heat exchangers are typically designed to fit within the confines of equipment enclosures, making them space-efficient. This compact design allows for easy integration into various types of cabinets and enclosures.

◆Closed System Protection:

The cabinet heat exchanger helps maintain a closed and controlled environment within the equipment enclosure. This protection is essential for sensitive electronic components, shielding them from contaminants and external elements.

◆Low Maintenance Requirements:

Cabinet heat exchanger generally have lower maintenance needs compared to traditional air conditioning systems. This can result in reduced downtime and cost savings over the long term.

◆Adaptability to Harsh Environments:

Cabinet Heat Exchanger is designed to regulate temperatures within electrical enclosures, ensuring optimal conditions for sensitive components. Built for harsh industrial environments, the electrical cabinet heat exchanger protects equipment from dust, moisture, and temperature extremes, maintaining operational integrity. Its robust construction makes it ideal for use in environments where equipment reliability is crucial.

◆Quiet Operation:

Cabinet heat exchanger often operate quietly, making them suitable for applications where noise levels need to be minimized. This is especially important in office settings or other environments where noise pollution is a concern.

Application of cabinet heat exchanger

Cabinet heat exchangers are devices designed to regulate and control the temperature within electronic cabinets or enclosures. They are commonly used in various industrial and technological applications to ensure that sensitive electronic components operate within their specified temperature range. Here are some common applications of cabinet heat exchangers:

◆Electronics Cooling:

Cabinet heat exchanger is widely used to cool electronic components, such as servers, power supplies, variable frequency drives (VFDs), and other sensitive equipment housed in cabinets or enclosures.

They help maintain optimal operating temperatures for electronic devices, preventing overheating and ensuring reliable performance.

◆Telecommunications:

Communication equipment, including base stations, routers, and switches, generates heat during operation. Cabinet heat exchanger is employed to dissipate this heat and maintain stable operating conditions.

In outdoor telecom cabinets, these heat exchangers can also protect equipment from external environmental factors while efficiently managing internal temperatures.

◆Industrial Automation:

Control cabinets in industrial settings often house electronics that control machinery and processes. Cabinet heat exchanger plays a crucial role in preventing overheating and ensuring the reliable operation of these control systems.

They help extend the lifespan of electronic components and reduce the risk of downtime due to heat-related issues.

◆Renewable Energy Systems:

In renewable energy applications, such as solar inverters and wind turbine control systems, cabinet heat exchanger is used to dissipate the heat generated during energy conversion and control processes.

They contribute to the efficiency and reliability of renewable energy systems by maintaining optimal operating temperatures.

◆Medical Equipment:

Various medical devices and equipment, such as imaging systems, analytical instruments, and diagnostic equipment, generate heat during operation. Cabinet heat exchanger is employed to regulate temperatures and ensure the proper functioning of these critical devices.

Military and Defense Systems:

Military electronics and defense systems often operate in challenging environments. Cabinet heat exchanger helps manage the heat generated by electronic components in ruggedized enclosures, ensuring the reliability of communication, surveillance, and control systems.

◆Data Centers:

In data center environments, where numerous servers and networking equipment are housed in cabinets or racks, cabinet heat exchanger can be used as part of the overall cooling strategy. They help maintain a controlled environment to prevent equipment overheating and optimize energy efficiency.

In summary, cabinet heat exchanger finds applications in a wide range of industries where maintaining optimal temperatures for electronic components is crucial for reliable and efficient operation. They play a vital role in preventing overheating, reducing energy consumption, and extending the lifespan of sensitive electronic equipment.