2050BTU/H Outdoor Electrical Enclosure Air Conditioner Product Introduction Video

2050BTU/H Outdoor Electrical Enclosure Air Conditioner Certificate

600W 2050BTU/H DC Powered Outdoor Electrical Enclosure Air Conditioner Introduction

DC powered electrical enclosure air conditioner is actively cooling by compressor ,it will remove the heat inside the cabinet to outside. It also can keep the dust and heat outside the cabinet,avoiding problems from using fan. The temperature inside the cabinet can be maintained at an ideal temperature for electrical components which effectively guarantee the stability of the electronic equipment and improves the reliability of the whole system.

600W 2050BTU/H DC Powered Outdoor Electrical Enclosure Air Conditioner Feature

Name | Technical parameter |

Model | DC106-1/A06NA0E |

Main power supply | -48VDC(-DC44~-59V) |

Cooling capacity(Rated) | 600W@L35/L35 2080btu/h@L35/L35 |

Power consumption(Rated) | 200W@L35/L35 |

Heating capacity(optional) | 500W |

Air flow | 150m3/h |

Cooling current (rated/Max.) | 4.2A/6.0A |

Work temp. range | -40℃~+55℃ |

Noise | 69dB(A) |

IP Grade | IP55,NEMA 4,NEMA 4X |

Net Weight | 14KG |

Refrigerant | R134a |

Note:@L35/L35 is Internal temperature 35℃, ambient temperature 35℃

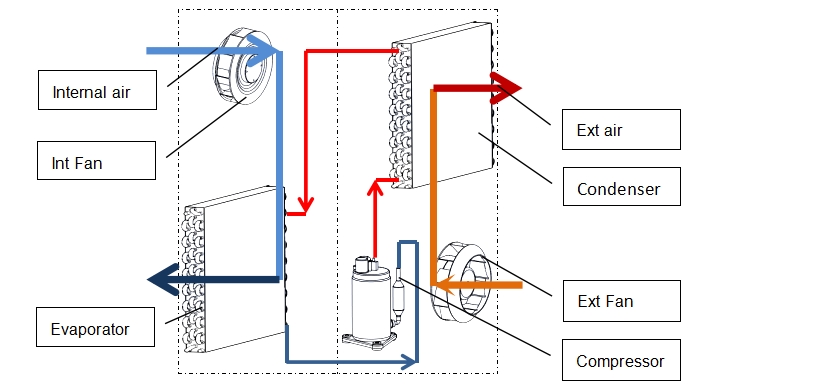

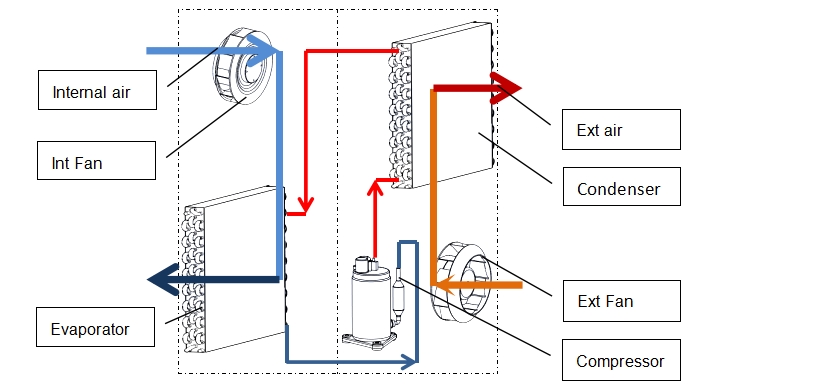

Thermal Cycle & Air Flow of 600W 2050BTU/H DC Powered Outdoor Electrical Enclosure Air Conditioner

DC Powered Outdoor Electrical Enclosure Air Conditioner Cooling Principle: the high-pressure refrigerant liquid in the system enters the evaporator and evaporates to absorb heat of the air in the cabinet, so the air is cooled, and the refrigerant that evaporates into gas in the evaporator is inhaled by the compressor and compressed into the high-pressure and high-temperature refrigerant gas, which enters the condenser and cooled to refrigerant liquid, and then re-enters the evaporator to cool the indoor air, and circulates accordingly

600W 2050BTU/H DC Powered Outdoor Electrical Enclosure Air Conditioner Features

◆ It also can keep the dust and heat outside the cabinet,avoiding problems from using fan;

◆ The temperature inside the cabinet can be maintained at an ideal temperature for electrical components which effectively guarantee the stability of the electronic equipment and improves the reliability of the whole system;

◆ Compact structure ,reasonable design and easy maintenance;

◆ Digital temperature controller and high precision of temperature control;

◆ The heating function and the hydrogen function is optional;

◆ Remote measuring, remote communication, remote control, which can realize multiple automatic protection and comprehensive self-testing function;

◆ Dry contact alarm output,NO/NC optional;

◆ LED display, all the settings can changed at the field

◆ Multiple self-protection design & visible monitoring interface, RS485 communication port (MODBUS-RTU);

◆ Fit for harsh condition (T3), R134a refrigerant .

600W 2050BTU/H DC Powered Outdoor Electrical Enclosure Air Conditioner Workshop Video