6800BTU/H 2000W AC NEMA 4X Electrical Enclosure Air Conditionier Product Video

6800BTU/H 2000W AC NEMA 4X Electrical Enclosure Air Conditioner Certificate

6800BTU/H 2000W AC NEMA 4X Electrical Enclosure Air Conditioner Introduction

Electrical Enclosure Air Conditionier also called electrical cabinet air conditioning is actively cooling with compressor, and it will remove the heat inside the cabinet to outside. It also can keep the dust and heat outside the cabinet, avoiding problems from using fan. The inside cabinet can be maintained at an ideal temperature for electrical components which effectively guarantees the stability of the electronic equipment and improves the reliability of the whole system.

6800BTU/H 2000W AC Nema 4X Electrical Enclosure Air Conditionier Feature

◆ This series of electrical cabinet ac units can be widely used for outdoor telecom cabinets, battery cabinets,electric cabinets and industry control cabinets etc.

◆ The protective level of internal and external circulation is IP55, which can protect cabinet to avoid moisture, dust, water. The air conditioner can also be indoor or outdoor installed.

◆ This system is suitable for high/low temperature working conditions of 55 ℃/-40 ℃.

◆ Digital temperature controller and high precision of temperature control.

6800BTU/H 2000W AC NEMA 4X Electrical Enclosure Air Conditionier Specification Parameter

Name | Electrical Enclosure Air Conditioner |

Model | AC120-2 |

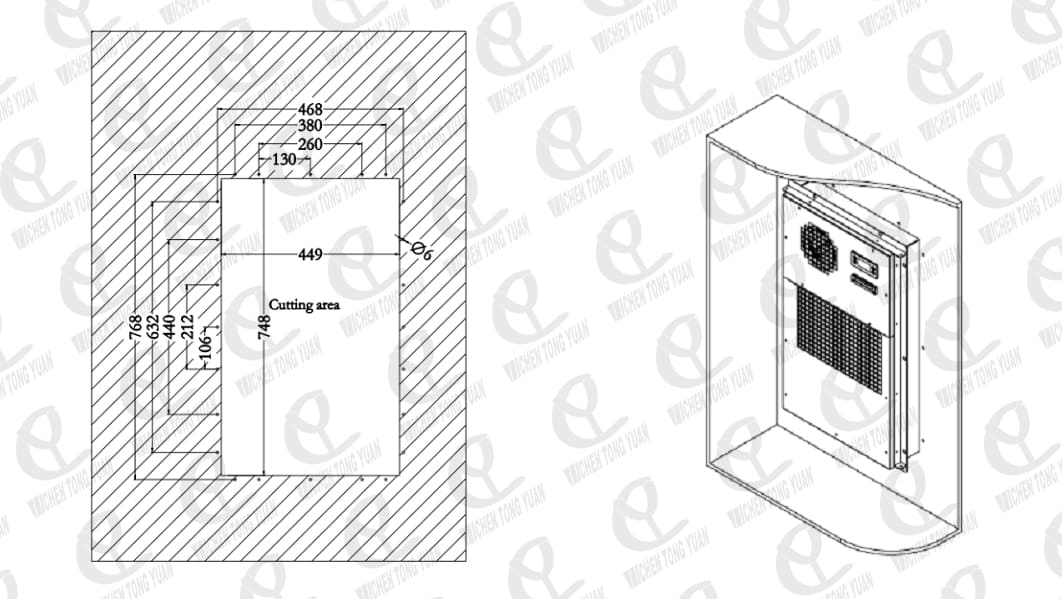

Mounting Method | Semi-embedded Mounting |

Power Supply | 220VAC±15% 50Hz/60Hz |

Cooling capacity | 2000W@L35/35 |

Power capacity | 780W@L35/35 |

Cooling capacity | 1200W@L35/55 |

Power capacity | 1050W@L35/55 |

Max Noise Level | 63dB(A) |

IP Grade | IP55 |

Heater | 1000W(Optional) |

Net Weight | 33kg |

Refrigerant | R134a |

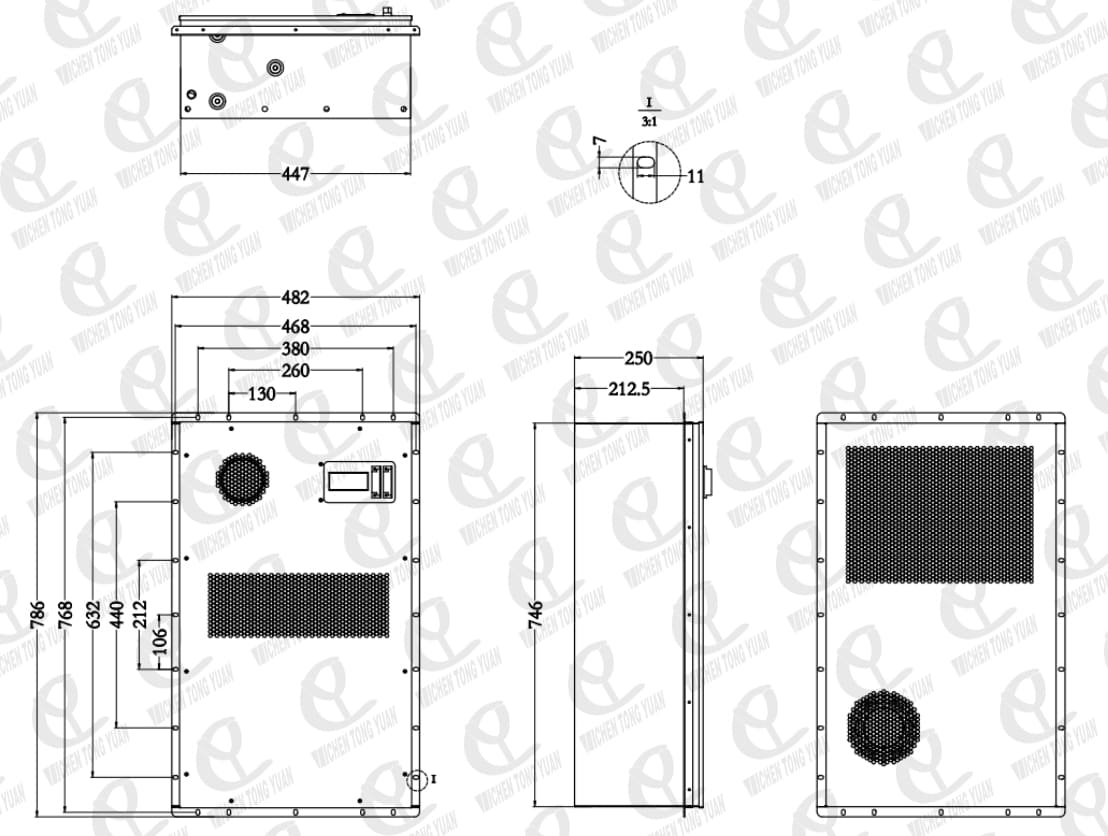

Dimensions | 786*482*250(mm) |

Note: The air conditioner has the function of power-on automatic start-up. Normally, no manual adjustment is needed.

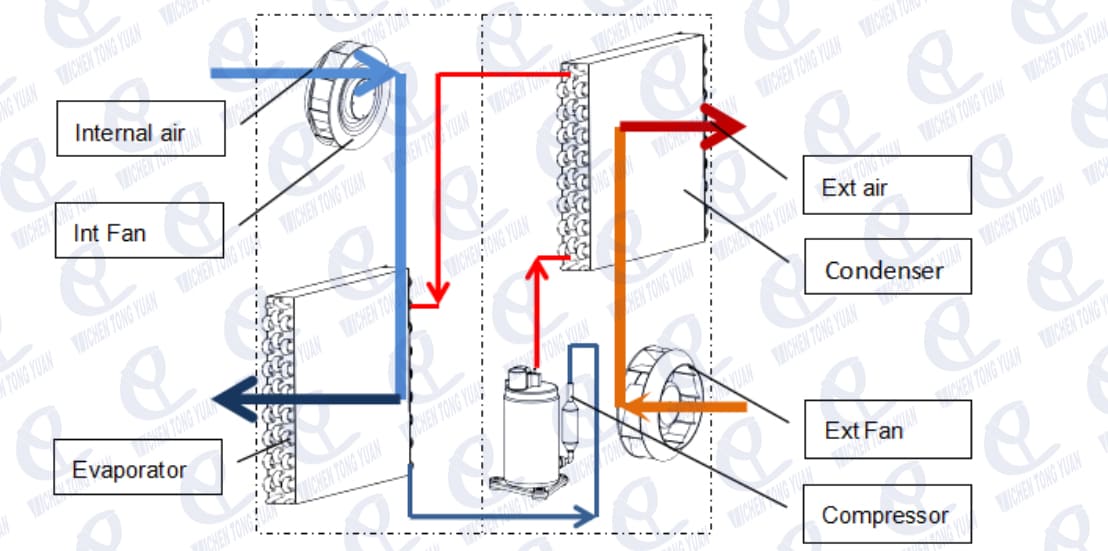

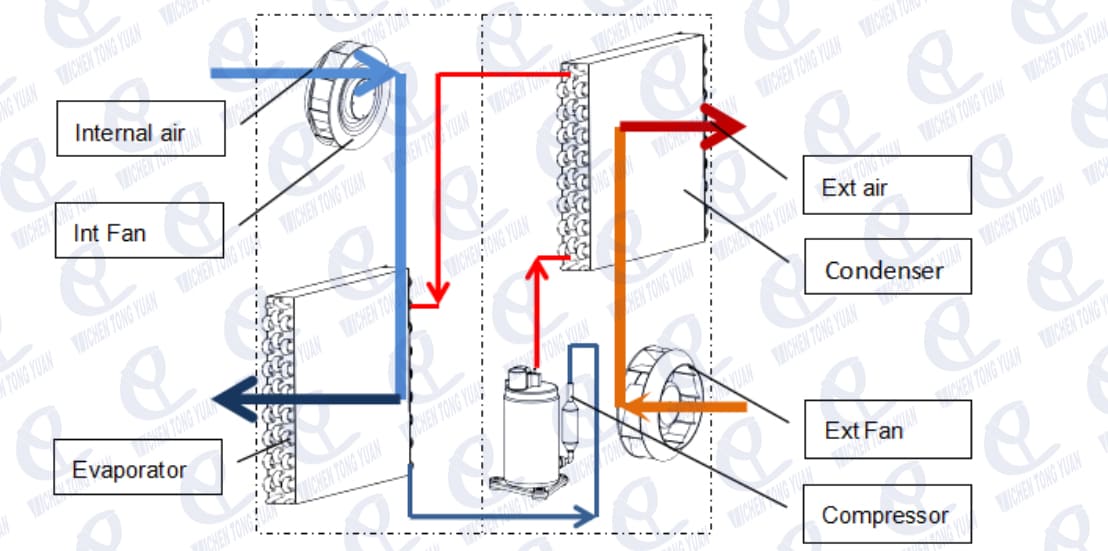

6800BTU/H 2000W AC NEMA4X Electrical Enclosure Air Conditionier Thermal cycle and air flowing

Electrical Enclosure Cooling: the high-pressure refrigerant liquid in the system enters the evaporator and evaporates to absorb heat of the air in the cabinet, so the air is cooled, and the refrigerant that evaporates into gas in the evaporator is inhaled by the compressor and compressed into the high-pressure and high-temperature refrigerant gas, which enters the condenser and cooled to refrigerant liquid, and then re-enters the evaporator to cool the indoor air, and circulates accordingly

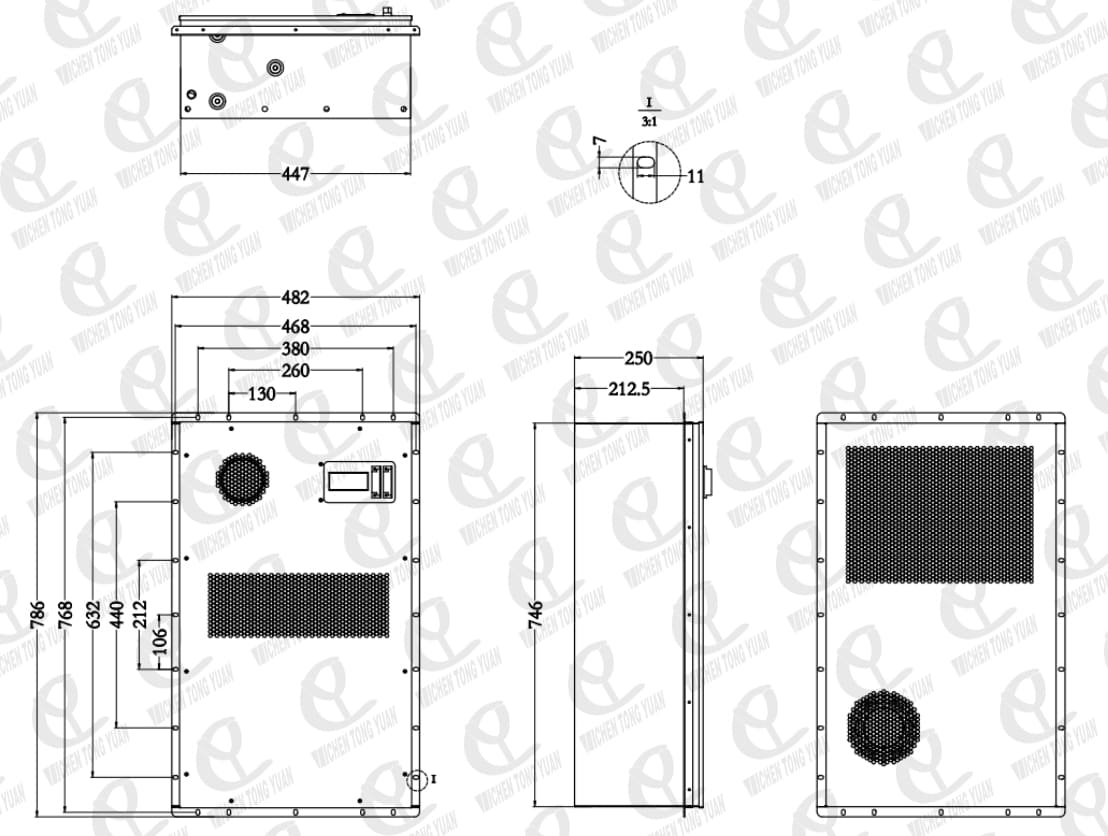

6800BTU/H 2000W AC Nema 4X Electrical Enclosure Air Conditioner Outer Dimension

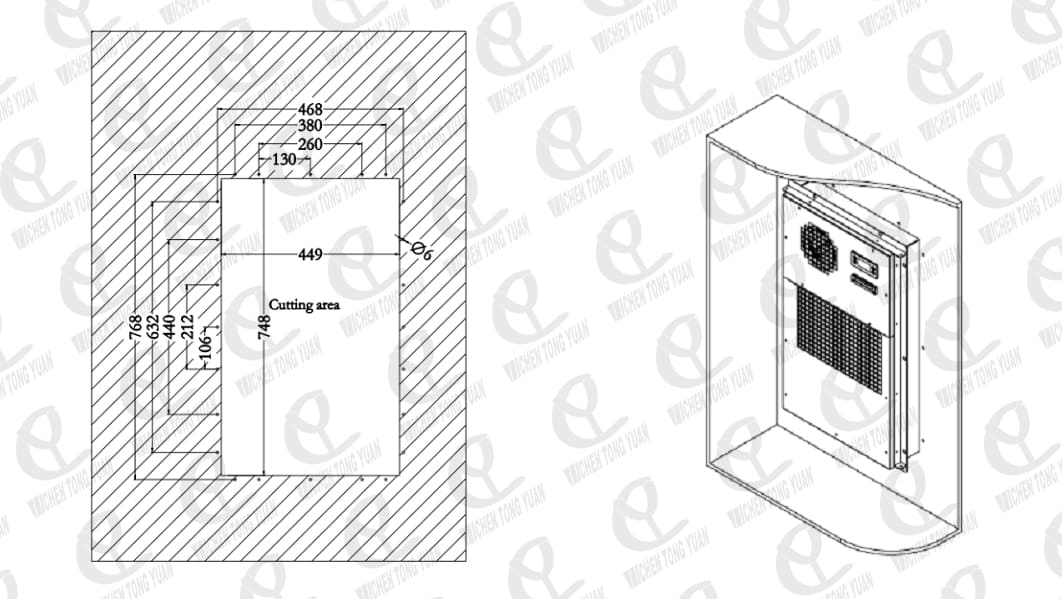

6800BTU/H 2000W AC Nema 4X Electrical Enclosure Air Conditioner Installation and wiring

Please design and install the product according to the installation holes drawings below

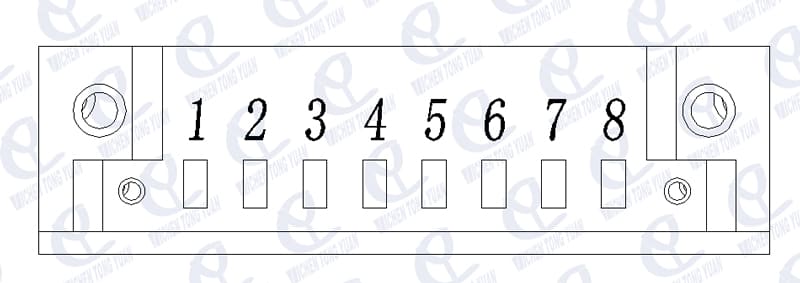

6800BTU/H 2000W AC Nema 4X Electrical Enclosure Air Conditioner Wiring

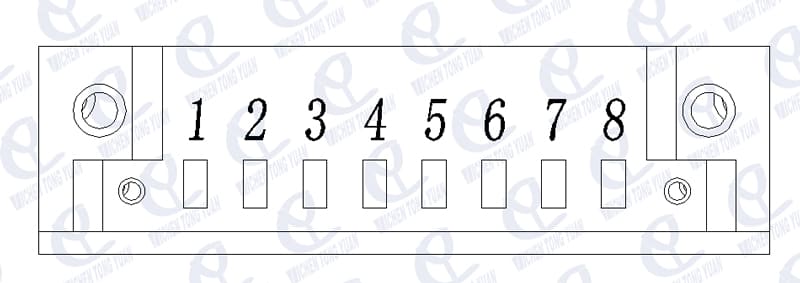

Equipped with a display LED in internal side of product, can display running, alarm information and parameter

Definition of Electrical Terminal

No. | Symbol | Definition | No. | Symbol | Definition |

1 | L | AC power-L line | 6 | ALR-NC | Alarm output-NC |

2 | N | AC power- N line | 7 | ALR-COM | Alarm output-COM |

3 | PE | Protective earthing wire | 8 | ALR-NO | Alarm output-NO |

4 | RS485- | Communication port B- |

|

|

|

5 | RS485+ | Communication port A+ |

|

|

|

Attention:

▶ It is strictly prohibited to turn the air conditioner upside down or lie flat during transportation or handling.

▶ Install vertically and make sure the polarity of wiring is correct and firm.

▶ To avoid objects blocking the air circulation at the inlet and outlet of internal and external circulation.

▶ If the protective cover is added, the vent area of the cover shall not be less than that of the air conditioner.