400W Outdoor Electrical Enclosure Air Conditioner 1360BTU/H Product Video

400W Outdoor Electrical Enclosure Air Conditioner 1360BTU/H Certificate

400W Outdoor Electrical Enclosure Air Conditioner 1360BTU/H Introduction

Outdoor electrical enclosure air conditioner is actively cooling by compressor ,it will remove the heat inside the cabinet to outside. It also can keep the dust and heat outside the cabinet,avoiding problems from using fan. The temperature inside the cabinet can be maintained at an ideal temperature for electrical components which effectively guarantee the stability of the electronic equipment and improves the reliability of the whole system.

400W Outdoor Electrical Enclosure Air Conditioner 1360BTU/H Specifications

1.Technical parameter of electrical enclosure air conditioner

Name | Technical parameter |

Model | AC104-2/A04NA1E |

Main power supply | 1~220VAC±15% 50Hz 1 phase |

Cooling capacity(Rated) | 400W@L35/L35 |

Power consumption(Rated) | 215W@L35/L35 |

Heating capacity(optional) | 500W |

Air flow | 110m3/h |

Cooling current (rated/Max.) | 1.4A/2.5A |

Work temp. range | -40℃~+55℃ |

Noise | 63dB(A) |

IP Grade | IP55,NEMA 4,NEMA 4X |

Net Weight | 15KG |

Refrigerant | R134a |

Note:@L35/L35 is Internal temperature 35℃, ambient temperature 35℃

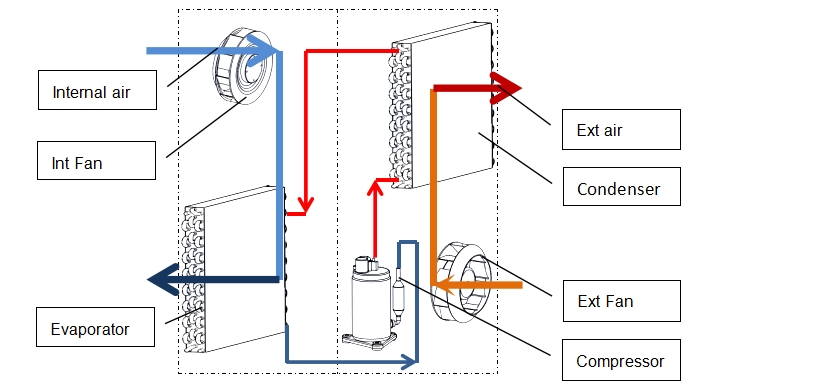

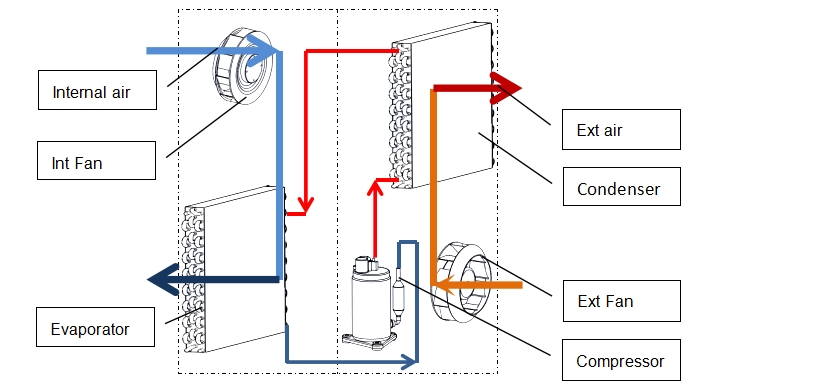

2. Thermal cycle and air flow of electrical enclosure air conditioner

Electrical Enclosure Air Conditioner Cooling Princple: the high-pressure refrigerant liquid in the system enters the evaporator and evaporates to absorb heat of the air in the cabinet, so the air is cooled, and the refrigerant that evaporates into gas in the evaporator is inhaled by the compressor and compressed into the high-pressure and high-temperature refrigerant gas, which enters the condenser and cooled to refrigerant liquid, and then re-enters the evaporator to cool the indoor air, and circulates accordingly.

400W Outdoor Electrical Enclosure Air Conditioner 1360BTU/H Features

◆Electrical enclosure air conditioner also can keep the dust and heat outside the cabinet,avoiding problems from using fan;

◆The temperature inside the cabinet can be maintained at an ideal temperature for electrical components which effectively guarantee the stability of the electronic equipment and improves the reliability of the whole system;

◆Compact structure ,reasonable design and easy maintenance;

◆Digital temperature controller and high precision of temperature control;

◆The Electrical enclosure air conditioner heating function and the hydrogen function is optional;

◆Remote measuring, remote communication, remote control, which can realize multiple automatic protection and comprehensive self-testing function;

◆Dry contact alarm output,NO/NC optional;

◆LED display, all the settings can changed at the field

◆Multiple self-protection design & visible monitoring interface, RS485 communication port (MODBUS-RTU);

◆Fit for harsh condition (T3), R134a refrigerant .

Outdoor Electrical Anclosure Air Conditioner Flexibility

Electrical enclosure air conditioner Cooling capacity ranges from 300w to 5000w

Voltage range :AC220V 50HZ,AC220V 60HZ,60HZ , AC110V60HZ ,DC48V

Electrical enclosure air conditioner is widely used for outdoor telecom cabinets ,battery cabinets,elecric cabinets and industry control cabinets etc.

Remote monitoring system supported, communication protocol is RS485

More option for Electrical enclosure air conditioner

1.220VAC 50HZ Power Electrical Enclosure Air Conditioner

Model | Voltage | Nominal cooling capacity(W) (L35/L35) | Nominal cooling capacity(Btu/hr) (L35/L35) | Power consumption(W)(L35/L35) | IP Grade | Heater (W)(option) | Internal air flow (m3/h) | Refrigerant | Noise (dbA) |

CYAC103-2 | 220VAC 50Hz | 300 | 1020 | 170 | IP55,NEMA 4, NEMA 4X | 500 | 100 | R134a | 56 |

CYAC104-2 | 220VAC 50Hz | 400 | 1360 | 215 | IP55,NEMA 4, NEMA 4X | 500 | 110 | R134a | 56 |

CYAC105-2 | 220VAC 50Hz | 500 | 1700 | 280 | IP55,NEMA 4, NEMA 4X | 500 | 120 | R134a | 56 |

CYAC110-2 | 220VAC 50Hz | 1000 | 3400 | 430 | IP55,NEMA 4, NEMA 4X | 1000 | 230 | R134a | 62 |

CYAC112-2 | 220VAC 50Hz | 1200 | 4080 | 498 | IP55,NEMA 4, NEMA 4X | 1000 | 240 | R134a | 62 |

CYAC113-2 | 220VAC 50Hz | 1300 | 4440 | 532 | IP55,NEMA 4, NEMA 4X | 1000 | 260 | R134a | 63 |

CYAC115-2 | 220VAC 50Hz | 1500 | 5100 | 600 | IP55,NEMA 4, NEMA 4X | 1000 | 300 | R134a | 63 |

CYAC120-2 | 220VAC 50Hz | 2000 | 6800 | 745 | IP55,NEMA 4, NEMA 4X | 1000 | 500 | R134a | 63 |

CYAC125-2 | 220VAC 50Hz | 2500 | 8500 | 846 | IP55,NEMA 4, NEMA 4X | 2000 | 560 | R134a | 63 |

CYAC130-2 | 220VAC 50Hz | 3000 | 10200 | 1240 | IP55,NEMA 4, NEMA 4X | 2000 | 720 | R134a | 63 |

CYAC135-2 | 220VAC 50Hz | 3500 | 11900 | 1360 | IP55,NEMA 4, NEMA 4X | 2000 | 1250 | R134a | 63 |

CYAC150-2 | 220VAC 50Hz | 5000 | 17000 | 2000 | IP55,NEMA 4, NEMA 4X | 2000 | 2300 | R134a | 63 |

220VAC 60HZ Power Electrical Enclosure Air Conditioner

Model | Voltage | Nominal cooling capacity(W) (L35/L35) | Nominal cooling capacity(Btu/hr) (L35/L35) | Power consumption(W)(L35/L35) | IP Grade | Heater (W)(option) | Internal air flow (m3/h) | Refrigerant | Noise (dbA) |

CYAC103-2 | 220VAC 60Hz | 300 | 1020 | 170 | IP55,NEMA 4, NEMA 4X | 500 | 100 | R134a | 56 |

CYAC104-2 | 220VAC 60Hz | 400 | 1360 | 215 | IP55,NEMA 4, NEMA 4X | 500 | 110 | R134a | 56 |

CYAC105-2 | 220VAC 60Hz | 500 | 1700 | 280 | IP55,NEMA 4, NEMA 4X | 500 | 120 | R134a | 56 |

CYAC110-2 | 220VAC 60Hz | 1000 | 3400 | 430 | IP55,NEMA 4, NEMA 4X | 1000 | 230 | R134a | 62 |

CYAC112-2 | 220VAC 60Hz | 1200 | 4080 | 498 | IP55,NEMA 4, NEMA 4X | 1000 | 240 | R134a | 62 |

CYAC113-2 | 220VAC 60Hz | 1300 | 4440 | 532 | IP55,NEMA 4, NEMA 4X | 1000 | 260 | R134a | 63 |

CYAC115-2 | 220VAC 60Hz | 1500 | 5100 | 600 | IP55,NEMA 4, NEMA 4X | 1000 | 300 | R134a | 63 |

CYAC120-2 | 220VAC 60Hz | 2000 | 6800 | 745 | IP55,NEMA 4, NEMA 4X | 1000 | 500 | R134a | 63 |

CYAC125-2 | 220VAC 60Hz | 2500 | 8500 | 846 | IP55,NEMA 4, NEMA 4X | 2000 | 560 | R134a | 63 |

CYAC130-2 | 220VAC 60Hz | 3000 | 10200 | 1240 | IP55,NEMA 4, NEMA 4X | 2000 | 720 | R134a | 63 |

CYAC135-2 | 220VAC 60Hz | 3500 | 11900 | 1360 | IP55,NEMA 4, NEMA 4X | 2000 | 1250 | R134a | 63 |

110V 60HZ Power Electrical Enclosure Air Conditioner

Model | Voltage | Nominal cooling capacity(W) (L35/L35) | Nominal cooling capacity(Btu/hr) (L35/L35) | Power consumption(W)(L35/L35) | IP Grade | Heater (W)(option) | Internal air flow (m3/h) | Refrigerant | Noise (dbA) |

CYAC103-2 | 110VAC 60Hz | 300 | 1020 | 170 | IP55,NEMA 4, NEMA 4X | 500 | 100 | R134a | 56 |

CYAC104-2 | 110VAC 60Hz | 400 | 1360 | 215 | IP55,NEMA 4, NEMA 4X | 500 | 110 | R134a | 56 |

CYAC105-2 | 110VAC 60Hz | 500 | 1700 | 280 | IP55,NEMA 4, NEMA 4X | 500 | 120 | R134a | 56 |

CYAC110-2 | 110VAC 60Hz | 1000 | 3400 | 430 | IP55,NEMA 4, NEMA 4X | 1000 | 230 | R134a | 62 |

CYAC112-2 | 110VAC 60Hz | 1200 | 4080 | 498 | IP55,NEMA 4, NEMA 4X | 1000 | 240 | R134a | 62 |

CYAC113-2 | 110VAC 60Hz | 1300 | 4440 | 532 | IP55,NEMA 4, NEMA 4X | 1000 | 260 | R134a | 63 |

CYAC115-2 | 110VAC 60Hz | 1500 | 5100 | 600 | IP55,NEMA 4, NEMA 4X | 1000 | 300 | R134a | 63 |

Other Electrical Enclosure Air Conditioners

How to Choose an Electrical Enclosure Air Conditioner

Selecting the right Electrical Enclosure Air Conditioner is crucial for maintaining the optimal performance of your equipment. Below are key factors to consider when choosing the right electric cabinet air conditioner or outdoor electrical cabinet air conditioner.

1. Acceptable Temperature Range

Ensure the Electrical Enclosure Air Conditioner maintains a temperature that falls within the acceptable range for your equipment. Too high or too low a temperature can cause damage or reduce efficiency.

2. Heat Load

The heat load generated by your equipment determines the cooling capacity needed. Choose an electrical control panel air conditioning unit that matches or exceeds the heat load to avoid overheating.

3. Highest Local Ambient Temperature

Check the highest local ambient temperature in the installation area. The outdoor telecom cabinet air conditioner should be capable of handling extreme environmental conditions to maintain internal cooling performance.

4. Noise Level

Consider the noise level of the Electrical Enclosure Air Conditioner. In sensitive environments, look for units designed to operate quietly to avoid disruptions.

5. Future Expansion

Choose an electrical enclosure air conditioner with extra capacity if you plan for future equipment upgrades or expansions. This will save you from having to replace the unit later.

Standards for Electrical Enclosure Air Conditioners

GB 4208 – Enclosure Protection Class

GB 4706.1 – Safety of electrical appliances

GB9237-2001 – Mechanical refrigerating systems safety

GB/T 17626.8 – Electromagnetic compatibility testing

These standards ensure that your Electrical Enclosure Air Conditioner operates safely and effectively.

Common Faults and Troubleshooting

1. Air Conditioner Not Working

Causes:

Solutions:

2. Insufficient Cooling

Causes:

Solutions:

3. Air Conditioner Stops Suddenly

Causes:

Solutions:

Warranty and Coverage

The Electrical Enclosure Air Conditioner comes with a 12-month warranty from operation start or 18 months from delivery, depending on the agreement. The warranty covers product defects but excludes damage caused by improper use or external factors.

Selecting the right Electrical Enclosure Air Conditioner ensures optimal equipment performance and longevity. Consider your system’s heat load, environmental conditions, and future needs to make the best choice.