Enclosure Air Conditioning 2500W Overview

Keep your sensitive electronics safe from overheating with our 2500W enclosure air conditioning unit. Designed for industrial cabinets, telecom enclosures, and outdoor electrical equipment, this AC system delivers consistent cooling performance, ensuring optimal operation even in extreme temperatures. Its robust construction and energy-efficient design make it an ideal solution for protecting critical equipment.

Key Benefits

High Cooling Capacity: Handles heat loads up to 2500W, keeping electronics safe.

Versatile Applications: Perfect for telecom enclosures, control panels, and electrical cabinets.

Reliable Operation: Maintains stable performance in high-temperature and dusty environments.

Energy Efficiency: Reduces power consumption and operational costs without compromising performance.

Features of the 2500W Cabinet Air Conditioner

Capable of handling up to 2500W heat load, making it suitable for medium to large enclosures.

Energy-Efficient Operation

Equipped with advanced refrigerant technology, this unit minimizes energy use while maximizing cooling efficiency.

Durable and Weather-Resistant

IP55-rated casing protects against dust, rain, and other harsh outdoor elements, ensuring long-term reliability.

Easy Installation and Maintenance

Compact design allows for easy mounting inside cabinets or enclosures, while accessible components simplify routine maintenance.

2500W Enclosure Air Conditioning Technical Parameter

Basic Parameter of this 2500w Electrical Enclosure Air Conditionging

Name | Cabinet air conditioner |

Model | AC125-2 |

Mounting Method | Semi-embedded Mounting |

Power Supply | 220VAC±15% 50Hz/60Hz |

Cooling capacity | 2500W@L35/35 |

Power capacity | 900W@L35/35 |

Cooling capacity | 1400W@L35/55 |

Power capacity | 1150W@L35/55 |

Max Noise Level | 63dB(A) |

IP Grade | IP55 |

Heater | 1000W(Optional) |

Net Weight | 37kg |

Refrigerant | R134a |

Dimensions | 1100*460*188(mm) |

Note:@L35/L35 is Internal temperature 35℃, ambient temperature 35℃

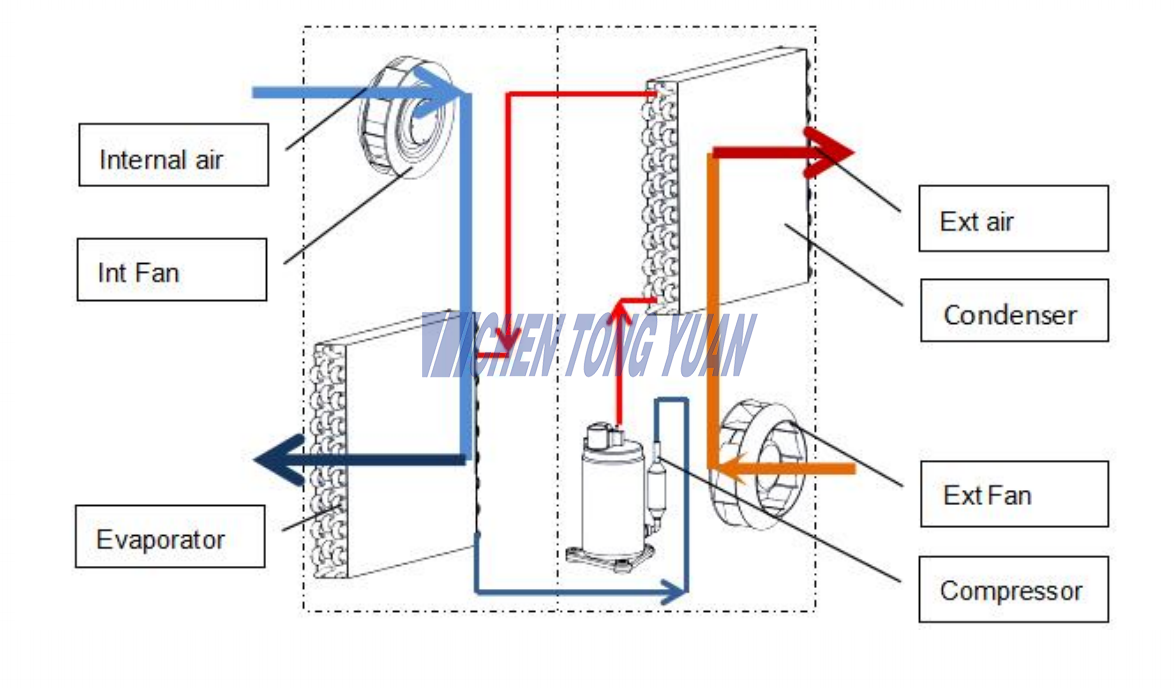

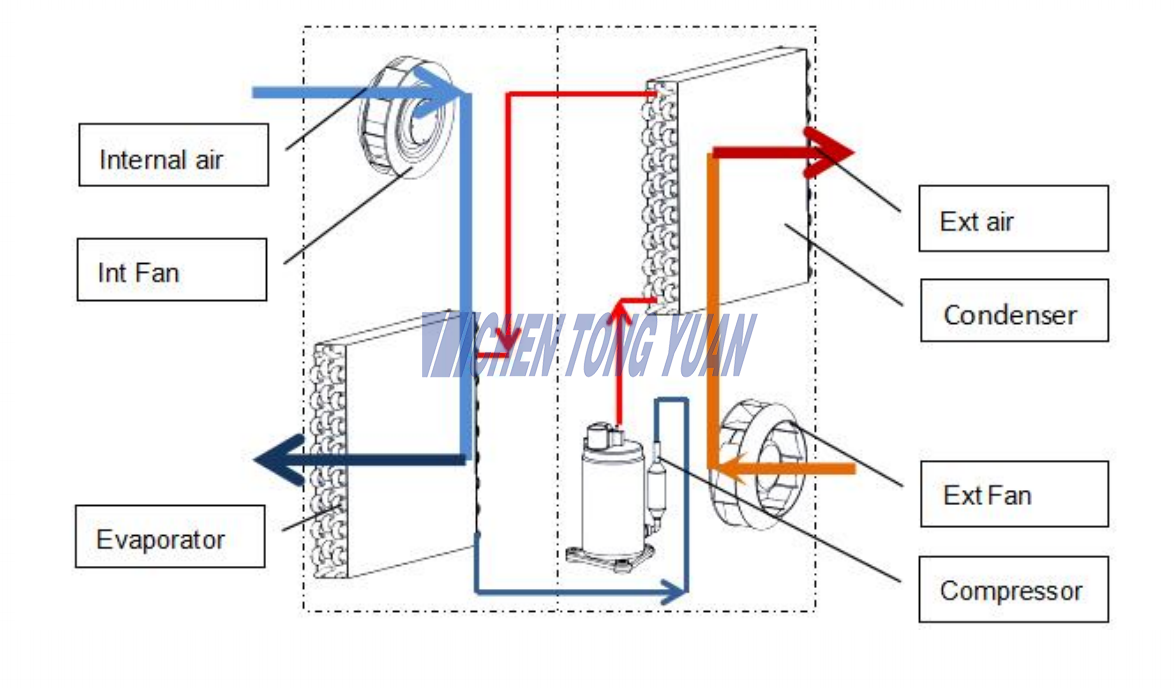

Air flow of Compressed Enclosure Air Conditioning

More options for Enclosure Air Conditioning

220VAC 50HZ Power Enclosure Air Conditioning

Model | Voltage | Nominal cooling capacity(W) (L35/L35) | Nominal cooling capacity(Btu/hr) (L35/L35) | Power consumption(W)(L35/L35) | IP Grade | Heater (W)(option) | Internal air flow (m3/h) | Refrigerant | Noise (dbA) |

CYAC103-2 | 220VAC 50Hz | 300 | 1020 | 170 | IP55,NEMA 4, NEMA 4X | 500 | 100 | R134a | 56 |

CYAC104-2 | 220VAC 50Hz | 400 | 1360 | 215 | IP55,NEMA 4, NEMA 4X | 500 | 110 | R134a | 56 |

CYAC105-2 | 220VAC 50Hz | 500 | 1700 | 280 | IP55,NEMA 4, NEMA 4X | 500 | 120 | R134a | 56 |

CYAC110-2 | 220VAC 50Hz | 1000 | 3400 | 430 | IP55,NEMA 4, NEMA 4X | 1000 | 230 | R134a | 62 |

CYAC112-2 | 220VAC 50Hz | 1200 | 4080 | 498 | IP55,NEMA 4, NEMA 4X | 1000 | 240 | R134a | 62 |

CYAC113-2 | 220VAC 50Hz | 1300 | 4440 | 532 | IP55,NEMA 4, NEMA 4X | 1000 | 260 | R134a | 63 |

CYAC115-2 | 220VAC 50Hz | 1500 | 5100 | 600 | IP55,NEMA 4, NEMA 4X | 1000 | 300 | R134a | 63 |

CYAC120-2 | 220VAC 50Hz | 2000 | 6800 | 745 | IP55,NEMA 4, NEMA 4X | 1000 | 500 | R134a | 63 |

CYAC125-2 | 220VAC 50Hz | 2500 | 8500 | 846 | IP55,NEMA 4, NEMA 4X | 2000 | 560 | R134a | 63 |

CYAC130-2 | 220VAC 50Hz | 3000 | 10200 | 1240 | IP55,NEMA 4, NEMA 4X | 2000 | 720 | R134a | 63 |

CYAC135-2 | 220VAC 50Hz | 3500 | 11900 | 1360 | IP55,NEMA 4, NEMA 4X | 2000 | 1250 | R134a | 63 |

CYAC150-2 | 220VAC 50Hz | 5000 | 17000 | 2000 | IP55,NEMA 4, NEMA 4X | 2000 | 2300 | R134a | 63 |

220VAC 60HZ Power Enclosure Air Conditioning

Model | Voltage | Nominal cooling capacity(W) (L35/L35) | Nominal cooling capacity(Btu/hr) (L35/L35) | Power consumption(W)(L35/L35) | IP Grade | Heater (W)(option) | Internal air flow (m3/h) | Refrigerant | Noise (dbA) |

CYAC103-2 | 220VAC 60Hz | 300 | 1020 | 170 | IP55,NEMA 4, NEMA 4X | 500 | 100 | R134a | 56 |

CYAC104-2 | 220VAC 60Hz | 400 | 1360 | 215 | IP55,NEMA 4, NEMA 4X | 500 | 110 | R134a | 56 |

CYAC105-2 | 220VAC 60Hz | 500 | 1700 | 280 | IP55,NEMA 4, NEMA 4X | 500 | 120 | R134a | 56 |

CYAC110-2 | 220VAC 60Hz | 1000 | 3400 | 430 | IP55,NEMA 4, NEMA 4X | 1000 | 230 | R134a | 62 |

CYAC112-2 | 220VAC 60Hz | 1200 | 4080 | 498 | IP55,NEMA 4, NEMA 4X | 1000 | 240 | R134a | 62 |

CYAC113-2 | 220VAC 60Hz | 1300 | 4440 | 532 | IP55,NEMA 4, NEMA 4X | 1000 | 260 | R134a | 63 |

CYAC115-2 | 220VAC 60Hz | 1500 | 5100 | 600 | IP55,NEMA 4, NEMA 4X | 1000 | 300 | R134a | 63 |

CYAC120-2 | 220VAC 60Hz | 2000 | 6800 | 745 | IP55,NEMA 4, NEMA 4X | 1000 | 500 | R134a | 63 |

CYAC125-2 | 220VAC 60Hz | 2500 | 8500 | 846 | IP55,NEMA 4, NEMA 4X | 2000 | 560 | R134a | 63 |

CYAC130-2 | 220VAC 60Hz | 3000 | 10200 | 1240 | IP55,NEMA 4, NEMA 4X | 2000 | 720 | R134a | 63 |

CYAC135-2 | 220VAC 60Hz | 3500 | 11900 | 1360 | IP55,NEMA 4, NEMA 4X | 2000 | 1250 | R134a | 63 |

110V 60HZ Power Enclosure Air Conditioning

Model | Voltage | Nominal cooling capacity(W) (L35/L35) | Nominal cooling capacity(Btu/hr) (L35/L35) | Power consumption(W)(L35/L35) | IP Grade | Heater (W)(option) | Internal air flow (m3/h) | Refrigerant | Noise (dbA) |

CYAC10 3-2 | 110VAC 60Hz | 300 | 1020 | 170 | IP55,NEMA 4, NEMA 4X | 500 | 100 | R134a | 56 |

CYAC104-2 | 110VAC 60Hz | 400 | 1360 | 215 | IP55,NEMA 4, NEMA 4X | 500 | 110 | R134a | 56 |

CYAC105-2 | 110VAC 60Hz | 500 | 1700 | 280 | IP55,NEMA 4, NEMA 4X | 500 | 120 | R134a | 56 |

CYAC110-2 | 110VAC 60Hz | 1000 | 3400 | 430 | IP55,NEMA 4, NEMA 4X | 1000 | 230 | R134a | 62 |

CYAC112-2 | 110VAC 60Hz | 1200 | 4080 | 498 | IP55,NEMA 4, NEMA 4X | 1000 | 240 | R134a | 62 |

CYAC113-2 | 110VAC 60Hz | 1300 | 4440 | 532 | IP55,NEMA 4, NEMA 4X | 1000 | 260 | R134a | 63 |

CYAC115-2 | 110VAC 60Hz | 1500 | 5100 | 600 | IP55,NEMA 4, NEMA 4X | 1000 | 300 | R134a | 63 |

Other Cabinet Cooling Solutions

How to Choose Enclosure Air Conditioning?

Selecting the right Outdoor Enclosure Air Conditioning system is crucial for ensuring optimal performance and longevity of your electrical equipment. When choosing an electrical cabinet cooling system, several factors must be considered to meet the specific needs of your equipment and environment.

Acceptable Temperature Range for Your Equipment

Every piece of electrical equipment has a defined operating temperature range. When selecting an Outdoor Electrical Enclosure Air Conditioning unit, it's essential to ensure that the unit can maintain a stable temperature within the acceptable range for your equipment.

Heat Load of Equipment

The cooling capacity required is directly related to the heat load generated by your equipment. Ensure that the electrical cabinet cooling unit you choose can handle the heat output of your equipment. Overloading the system can lead to inefficient cooling and potential equipment failure.

The Highest Local Ambient Temperature

Consider the maximum ambient temperature in the location where the Outdoor Electrical Enclosure Air Conditioning system will be installed. The cooling system must be designed to handle these conditions efficiently. Systems that operate in high-temperature environments should be able to manage this load without compromising performance.

Noise Level

Depending on where the electrical cabinet cooling unit is installed, the noise level may be an important consideration. In noise-sensitive environments, selecting a quieter unit is crucial to minimize disruption. Make sure to check the noise specifications of your chosen system.

Future Expansion

As your equipment grows, so will its cooling needs. Consider the possibility of future expansion when selecting your Outdoor Electrical Enclosure Air Conditioning system. Choose a system that offers flexibility for scaling up in terms of both capacity and configuration.