Product Video

Certificate

Introduction

Outdoor cabinet air conditioner or industrial panel air conditioner is actively cooling by compressor ,it will remove the heat inside the cabinet to outside. It also can keep the dust and heat outside the cabinet,avoiding problems from using fan. The temperature inside the cabinet can be maintained at an ideal temperature for electrical components which effectively guarantee the stability of the electronic equipment and improves the reliability of the whole system.

Small Cabinet Air Conditioner Specifications

1) Technical parameter of small cabinet air conditioner

Name | Technical parameter |

Model | AC103-2/A03NA1E |

Main power supply | 1~220VAC±15% 50Hz 1 phase |

Cooling capacity(Rated) | 300W@L35/L35 |

Power consumption(Rated) | 170W@L35/L35 |

Heating capacity(optional) | 500W |

Air flow | 100m3/h |

Cooling current (rated/Max.) | 1.4A/2.5A |

Work temp. range | -40℃~+55℃ |

Noise | 60dB(A) |

IP Grade | IP55,NEMA 4,NEMA 4X |

Net Weight | 15KG |

Refrigerant | R134a |

Note:@L35/L35 is Internal temperature 35℃, ambient temperature 35℃

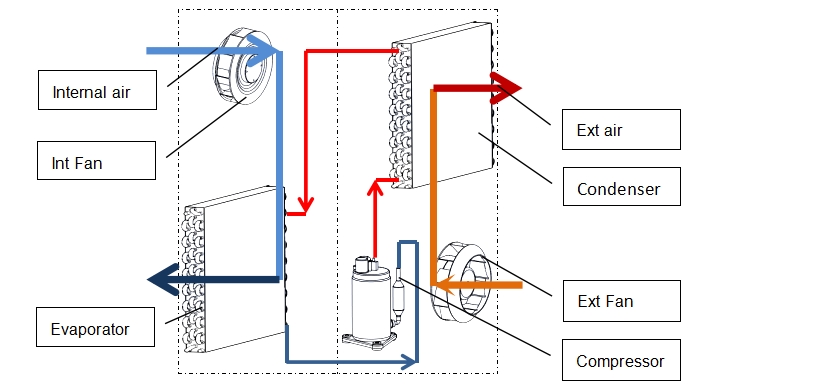

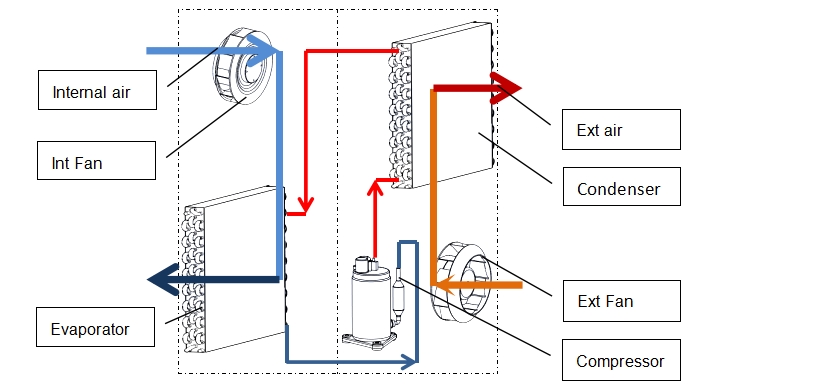

2) Thermal cycle and air flow of small cabinet air conditioner

Cooling: the high-pressure refrigerant liquid in the system enters the evaporator and evaporates to absorb heat of the air in the cabinet, so the air is cooled, and the refrigerant that evaporates into gas in the evaporator is inhaled by the compressor and compressed into the high-pressure and high-temperature refrigerant gas, which enters the condenser and cooled to refrigerant liquid, and then re-enters the evaporator to cool the indoor air, and circulates accordingly

Small cabinet air conditioner features

◆Small cabinet air conditioner also can keep the dust and heat outside the cabinet,avoiding problems from using fan;

◆The temperature inside the cabinet can be maintained at an ideal temperature for electrical components which effectively guarantee the stability of the electronic equipment and improves the reliability of the whole system;

◆Compact structure ,reasonable design and easy maintenance;

◆Digital temperature controller and high precision of temperature control;

◆The heating function and the hydrogen function is optional;

◆Remote measuring, remote communication, remote control, which can realize multiple automatic protection and comprehensive self-testing function;

◆Dry contact alarm output,NO/NC optional;

◆LED display, all the settings can changed at the field

◆Multiple self-protection design & visible monitoring interface, RS485 communication port (MODBUS-RTU);

◆Fit for harsh condition (T3), R134a refrigerant.

Small cabinet air conditioner Flexibility

Cooling capacity ranges from 300w to 5000w

Voltage range :AC220V 50HZ,AC220V 60HZ,60HZ , AC110V60HZ ,DC48V

Widely used for outdoor telecom cabinets ,battery cabinets,elecric cabinets and industry control cabinets etc.

Remote monitoring system supported, communication protocol is RS485

More option for small cabinet air conditioner

1) 220VAC 50HZ power small cabinet air conditioner

Model | Voltage | Nominal cooling capacity(W) (L35/L35) | Nominal cooling capacity(Btu/hr) (L35/L35) | Power consumption(W)(L35/L35) | IP Grade | Heater (W)(option) | Internal air flow (m3/h) | Refrigerant | Noise (dbA) |

CYAC103-2 | 220VAC 50Hz | 300 | 1020 | 170 | IP55,NEMA 4, NEMA 4X | 500 | 100 | R134a | 56 |

CYAC104-2 | 220VAC 50Hz | 400 | 1360 | 215 | IP55,NEMA 4, NEMA 4X | 500 | 110 | R134a | 56 |

CYAC105-2 | 220VAC 50Hz | 500 | 1700 | 280 | IP55,NEMA 4, NEMA 4X | 500 | 120 | R134a | 56 |

CYAC110-2 | 220VAC 50Hz | 1000 | 3400 | 430 | IP55,NEMA 4, NEMA 4X | 1000 | 230 | R134a | 62 |

CYAC112-2 | 220VAC 50Hz | 1200 | 4080 | 498 | IP55,NEMA 4, NEMA 4X | 1000 | 240 | R134a | 62 |

CYAC113-2 | 220VAC 50Hz | 1300 | 4440 | 532 | IP55,NEMA 4, NEMA 4X | 1000 | 260 | R134a | 63 |

CYAC115-2 | 220VAC 50Hz | 1500 | 5100 | 600 | IP55,NEMA 4, NEMA 4X | 1000 | 300 | R134a | 63 |

CYAC120-2 | 220VAC 50Hz | 2000 | 6800 | 745 | IP55,NEMA 4, NEMA 4X | 1000 | 500 | R134a | 63 |

CYAC125-2 | 220VAC 50Hz | 2500 | 8500 | 846 | IP55,NEMA 4, NEMA 4X | 2000 | 560 | R134a | 63 |

CYAC130-2 | 220VAC 50Hz | 3000 | 10200 | 1240 | IP55,NEMA 4, NEMA 4X | 2000 | 720 | R134a | 63 |

CYAC135-2 | 220VAC 50Hz | 3500 | 11900 | 1360 | IP55,NEMA 4, NEMA 4X | 2000 | 1250 | R134a | 63 |

CYAC150-2 | 220VAC 50Hz | 5000 | 17000 | 2000 | IP55,NEMA 4, NEMA 4X | 2000 | 2300 | R134a | 63 |

2)220VAC 60HZ power outdoor cabinet air conditioner

Model | Voltage | Nominal cooling capacity(W) (L35/L35) | Nominal cooling capacity(Btu/hr) (L35/L35) | Power consumption(W)(L35/L35) | IP Grade | Heater (W)(option) | Internal air flow (m3/h) | Refrigerant | Noise (dbA) |

CYAC103-2 | 220VAC 60Hz | 300 | 1020 | 170 | IP55,NEMA 4, NEMA 4X | 500 | 100 | R134a | 56 |

CYAC104-2 | 220VAC 60Hz | 400 | 1360 | 215 | IP55,NEMA 4, NEMA 4X | 500 | 110 | R134a | 56 |

CYAC105-2 | 220VAC 60Hz | 500 | 1700 | 280 | IP55,NEMA 4, NEMA 4X | 500 | 120 | R134a | 56 |

CYAC110-2 | 220VAC 60Hz | 1000 | 3400 | 430 | IP55,NEMA 4, NEMA 4X | 1000 | 230 | R134a | 62 |

CYAC112-2 | 220VAC 60Hz | 1200 | 4080 | 498 | IP55,NEMA 4, NEMA 4X | 1000 | 240 | R134a | 62 |

CYAC113-2 | 220VAC 60Hz | 1300 | 4440 | 532 | IP55,NEMA 4, NEMA 4X | 1000 | 260 | R134a | 63 |

CYAC115-2 | 220VAC 60Hz | 1500 | 5100 | 600 | IP55,NEMA 4, NEMA 4X | 1000 | 300 | R134a | 63 |

CYAC120-2 | 220VAC 60Hz | 2000 | 6800 | 745 | IP55,NEMA 4, NEMA 4X | 1000 | 500 | R134a | 63 |

CYAC125-2 | 220VAC 60Hz | 2500 | 8500 | 846 | IP55,NEMA 4, NEMA 4X | 2000 | 560 | R134a | 63 |

CYAC130-2 | 220VAC 60Hz | 3000 | 10200 | 1240 | IP55,NEMA 4, NEMA 4X | 2000 | 720 | R134a | 63 |

CYAC135-2 | 220VAC 60Hz | 3500 | 11900 | 1360 | IP55,NEMA 4, NEMA 4X | 2000 | 1250 | R134a | 63 |

3)110V 60HZ power outdoor cabinet air conditioner

Model | Voltage | Nominal cooling capacity(W) (L35/L35) | Nominal cooling capacity(Btu/hr) (L35/L35) | Power consumption(W)(L35/L35) | IP Grade | Heater (W)(option) | Internal air flow (m3/h) | Refrigerant | Noise (dbA) |

CYAC103-2 | 110VAC 60Hz | 300 | 1020 | 170 | IP55,NEMA 4, NEMA 4X | 500 | 100 | R134a | 56 |

CYAC104-2 | 110VAC 60Hz | 400 | 1360 | 215 | IP55,NEMA 4, NEMA 4X | 500 | 110 | R134a | 56 |

CYAC105-2 | 110VAC 60Hz | 500 | 1700 | 280 | IP55,NEMA 4, NEMA 4X | 500 | 120 | R134a | 56 |

CYAC110-2 | 110VAC 60Hz | 1000 | 3400 | 430 | IP55,NEMA 4, NEMA 4X | 1000 | 230 | R134a | 62 |

CYAC112-2 | 110VAC 60Hz | 1200 | 4080 | 498 | IP55,NEMA 4, NEMA 4X | 1000 | 240 | R134a | 62 |

CYAC113-2 | 110VAC 60Hz | 1300 | 4440 | 532 | IP55,NEMA 4, NEMA 4X | 1000 | 260 | R134a | 63 |

CYAC115-2 | 110VAC 60Hz | 1500 | 5100 | 600 | IP55,NEMA 4, NEMA 4X | 1000 | 300 | R134a | 63 |

Other outdoor cabinet climate control

How to Choose Control Cabinet Cooling System?

Selecting the right control cabinet cooling system is crucial for maintaining optimal operating conditions. As an air conditioning industry expert, I recommend a systematic approach when evaluating enclosure air conditioning solutions. Whether you opt for robust enclosure ac units, advanced enclosure air conditioners, or a compact small cabinet air conditioner, careful consideration will ensure reliable and efficient performance.

Key Considerations for Selecting an Enclosure Air Conditioning System

By carefully weighing these factors, you can select a cabinet climate control system that meets the specific needs of your equipment and environmental conditions.

Normative Standards for Enclosure Air Conditioning

Compliance with industry standards is essential for safety and reliability. Key normative standards include:

GB 4208 – Enclosure Protection Class

GB 4706.1 – Safety of Household and Similar Electrical Appliances

GB9237-2001 – Mechanical Refrigerating Systems Used for Cooling and Heating – Safety Requirements

GB/T 17626.8 – Electromagnetic Compatibility - Testing and Measurement Techniques - Power Frequency Magnetic Field Immunity Test

These standards ensure that your selected enclosure ac and enclosure air conditioners operate within defined safety and performance parameters.

Common Fault Analysis and Troubleshooting for Enclosure Air Conditioners

| Fault State | Analysis of the Reasons | Solutions |

| High Cabinet Temperature but No Cooling Operation | 1) Power failure or no power.2) Cooling set temperature exceeds cabinet temperature.3) System fault in the enclosure air conditioning unit. | 1) Verify power supply and circuit integrity.2) Adjust cooling settings as required.3) Contact professional maintenance. |

| Air Conditioner Running but Cooling Effect is Poor | 1) Cooling capacity does not match the load.2) Excessively high ambient temperature.3) Other system faults. | 1) Consider upgrading or adding another enclosure ac.2) Ensure the unit is used within its specified range.3) Seek professional maintenance. |

| Sudden Shutdown Despite Normal Electrical System | 1) Cabinet temperature has reached or exceeded the cooling set point.2) Additional system faults. | 1) Readjust the cooling set temperature based on operational needs.2) Contact professional maintenance for further diagnostics. |

Warranty for Outdoor Enclosure Air Conditioners

Warranty Period

The product guarantee period is typically 12 months from the time the product begins operation or up to 18 months from the delivery date, depending on the contractual agreement.

Warranty Coverage

During the warranty period, any faults attributed to quality issues with the enclosure air conditioning solution will be repaired free of charge, provided that the product label is available. However, the warranty does not cover:

Failures occurring after the warranty period expires.

Inability to provide the product label (usually affixed to the nameplate).

Faults resulting from abnormal environmental conditions or improper installation, maintenance, or operation.

Issues not directly caused by equipment failure, including those from external equipment or software interference.

Damage due to unauthorized disassembly or modifications.

Failures caused by force majeure events such as fires, earthquakes, floods, or similar incidents.

In summary, a well-chosen control cabinet cooling system—whether it is an enclosure air conditioning solution, an enclosure ac unit, or a small cabinet air conditioner—ensures that your equipment operates safely and efficiently while also providing room for future expansion.