Advantages of Control Panel Air Conditioner

Control Panel Air Conditioner is essential for maintaining optimal operating conditions for electrical and electronic components inside control panels. Here are the key advantages of control panel ac:

1. Temperature Regulation

Control Panel Air Conditioner effectively regulates temperature, preventing overheating of sensitive electronic components, which can lead to system failures or reduced performance.

Benefits:

2. Prevention of Dust and Contaminants

Control Panel AC helps keep dust, dirt, and other airborne contaminants out of the control panel, ensuring clean internal conditions and extending the lifespan of components.

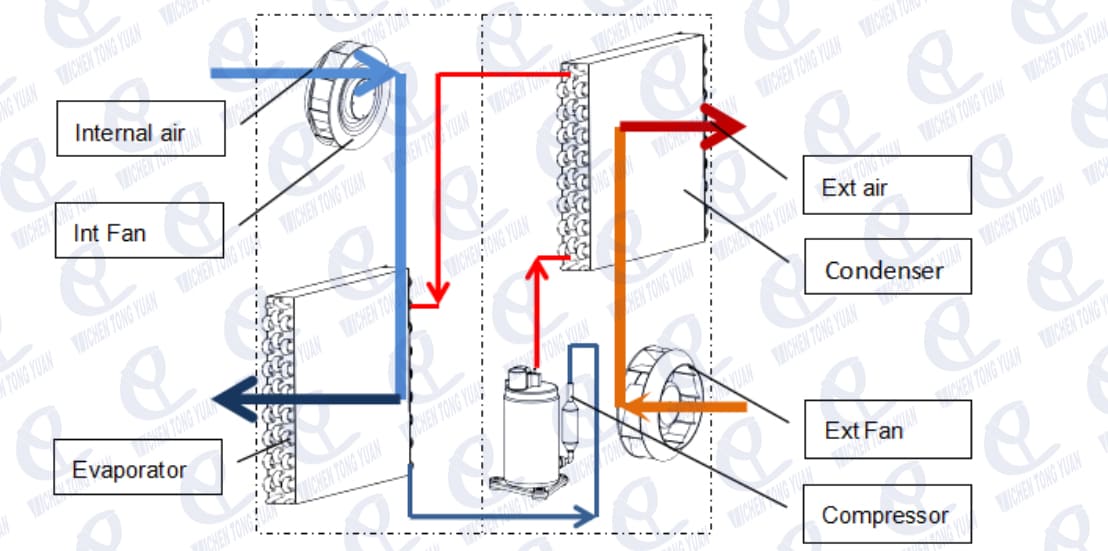

How It Works:

3. Humidity Control

By managing humidity levels inside the panel, Control Panel Air Conditioner reduces the risk of moisture-related issues such as corrosion, short circuits, and condensation buildup.

Why It Matters:

4. Extended Equipment Lifespan

Maintaining a stable temperature and humidity level helps reduce wear and tear on electrical components, leading to longer operational life and lower maintenance costs.

Long-Term Benefits:

5. Enhanced Energy Efficiency

Modern Control Panel Air Conditioner units are designed with energy-efficient features that help reduce power consumption while maintaining optimal cooling performance.

Key Features:

6. Improved System Reliability

A consistent and controlled cooling environment ensures that Control Panel Air Conditioner functions efficiently without unexpected shutdowns, improving overall system reliability and uptime.

Impact on Reliability:

7. Protection Against External Environmental Factors

For control panels installed in harsh environments, Control Panel Air Conditioner provides a protective barrier against extreme temperatures, humidity, and contaminants like oil, chemicals, and industrial fumes.

Protection Features:

8. Reduced Maintenance and Downtime

By preventing overheating and contamination, Control Panel Air Conditioner reduces the frequency of maintenance and unexpected failures, minimizing costly downtime.

Why It Matters:

9. Customizable Control Panel Cooling Solutions

Many Control Panel Air Conditioner models come in various sizes, cooling capacities, and configurations to meet specific industrial requirements, ensuring optimal performance for different applications.

Available Options:

Conclusion

Control Panel Air Conditioner plays a crucial role in maintaining the efficiency and longevity of electrical systems. By providing temperature regulation, humidity control, and protection from contaminants, Control Panel Air Conditioner ensures reliable and uninterrupted operation, making it a valuable investment for industrial and commercial applications.